Oil fume purification all-in-one machine

An oil fume purification and all-in-one machine technology, which is applied in the field of oil fume purification, can solve the problems of the all-in-one machine oil suction fume wind pressure loss attenuation, limited improvement, and low oil suction efficiency, so as to solve the problem of wind pressure loss attenuation, improve suction, and improve filtration. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

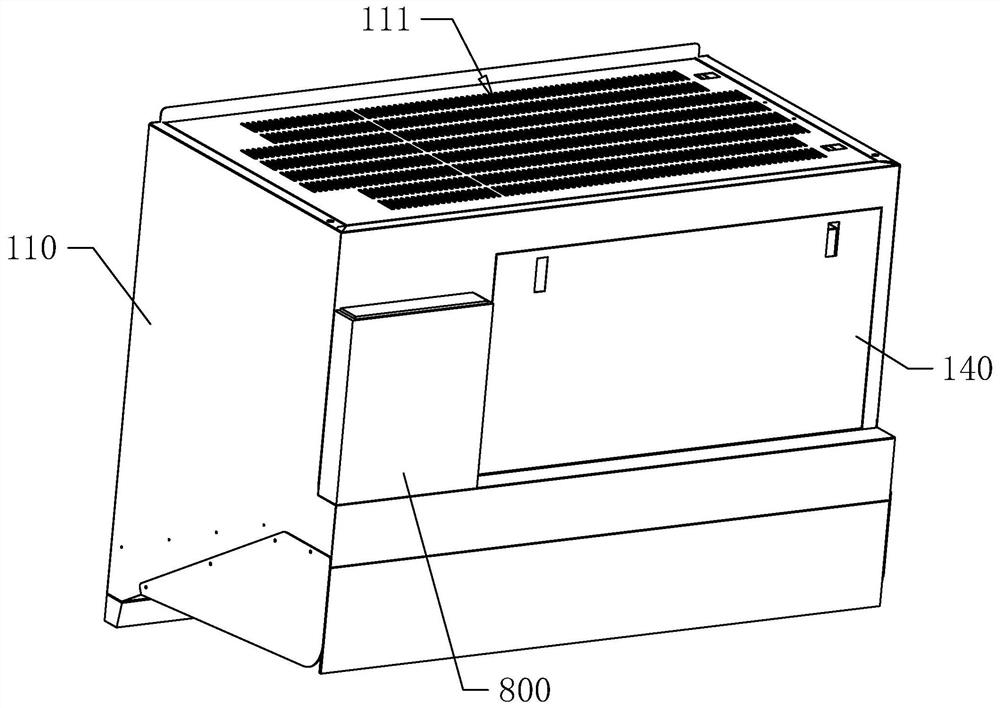

[0052] Example 1: A kind of oil purification one, such as figure 1 with figure 2 As shown, including the chassis 100, the chassis 100 includes an upper wind turbine 110 and a smoking cover 120 disposed lower in the lower portion of the wind turbine 110, and the top of the wind turbine 110 is provided with an exhaust port 111, and a sugar cover 120 is provided with a suction port. 121.

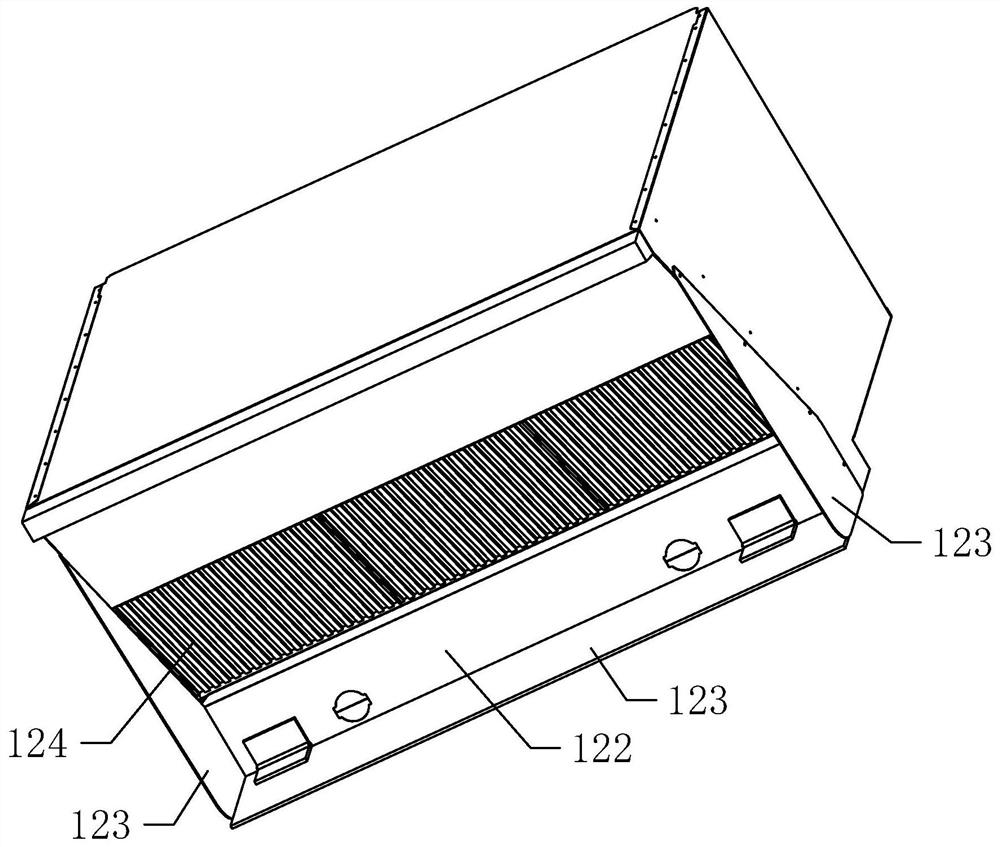

[0053] Refer image 3 The smoking shade 120 includes a main board 122 and a three-stop plate 123, and one end of the main board 122 is connected to the bottom of the winding chassis 110, and the other end is tilted upwardly connects the bottom of the front of the wind in the winder box 110. One end portion of the front connection of the wind in the winder box 110 is provided with a horizontal setting for mounting the light or the like.

[0054] The intake port 121 is provided on the main board 122, and the intake port 121 is detachably attached to the front oil-fat filter 124, and the oil fat filter...

Embodiment 2

[0089] Example 2: Such as Figure 10 As shown, the difference in the outer casing of the boost filter fan 200 is fixed to the outer casing of the booster filter fan 200, and the mounting plate 710 and the boost filter fan 200 housing vertical setting, mounting plate 710 Temperature sensor 700 is installed.

[0090] The temperature sensor 700 is configured to detect the temperature of the fume gas in the intake of the booster filter fan, and transmit the corresponding detection signal. When the detection temperature is less than or equal to the preset temperature, the boost pump does not start the atomizing nozzle 600 does not spray water When the detection temperature is greater than the preset temperature, the detection signal triggers the booster pump start, and the atomizing head 600 begins water. Among them, it is also possible to set it to the detection temperature than the preset temperature, the boost pump is not activated, greater than or equal to the preset temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com