Single-electrode-plugging-prevention socket

A socket and single-pole technology, applied in the direction of preventing contact with live contacts, electrical components, coupling devices, etc., can solve the problems of complex socket structure, difficult plugging and unplugging, short service life, etc., to improve the safety of electricity consumption, Improve sliding stability and avoid accidental electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

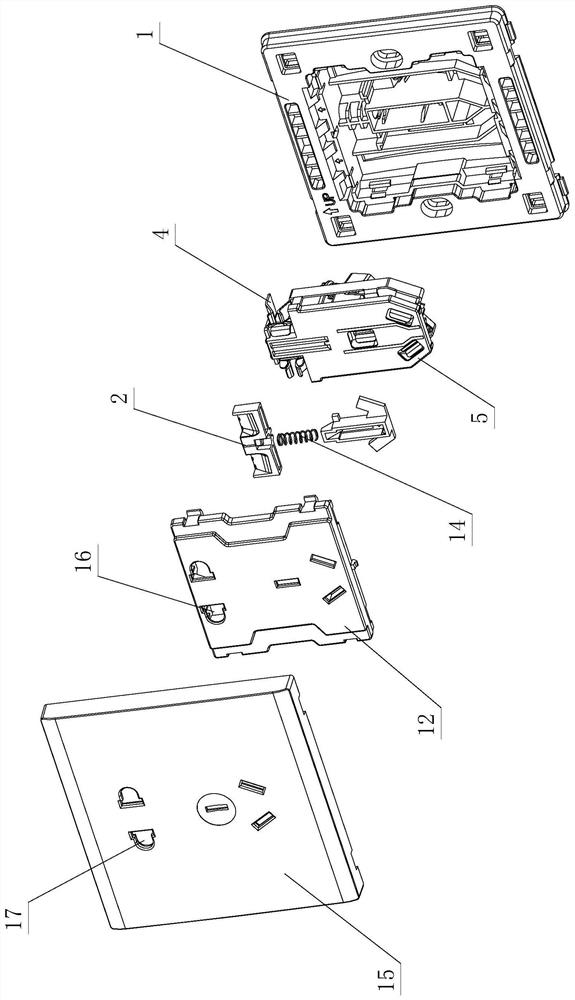

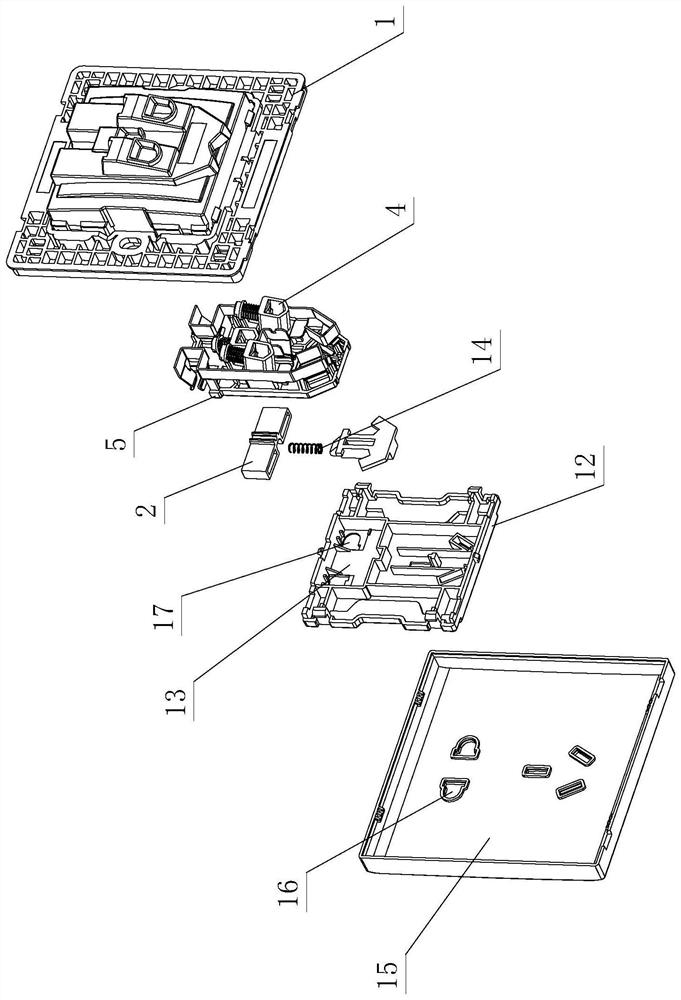

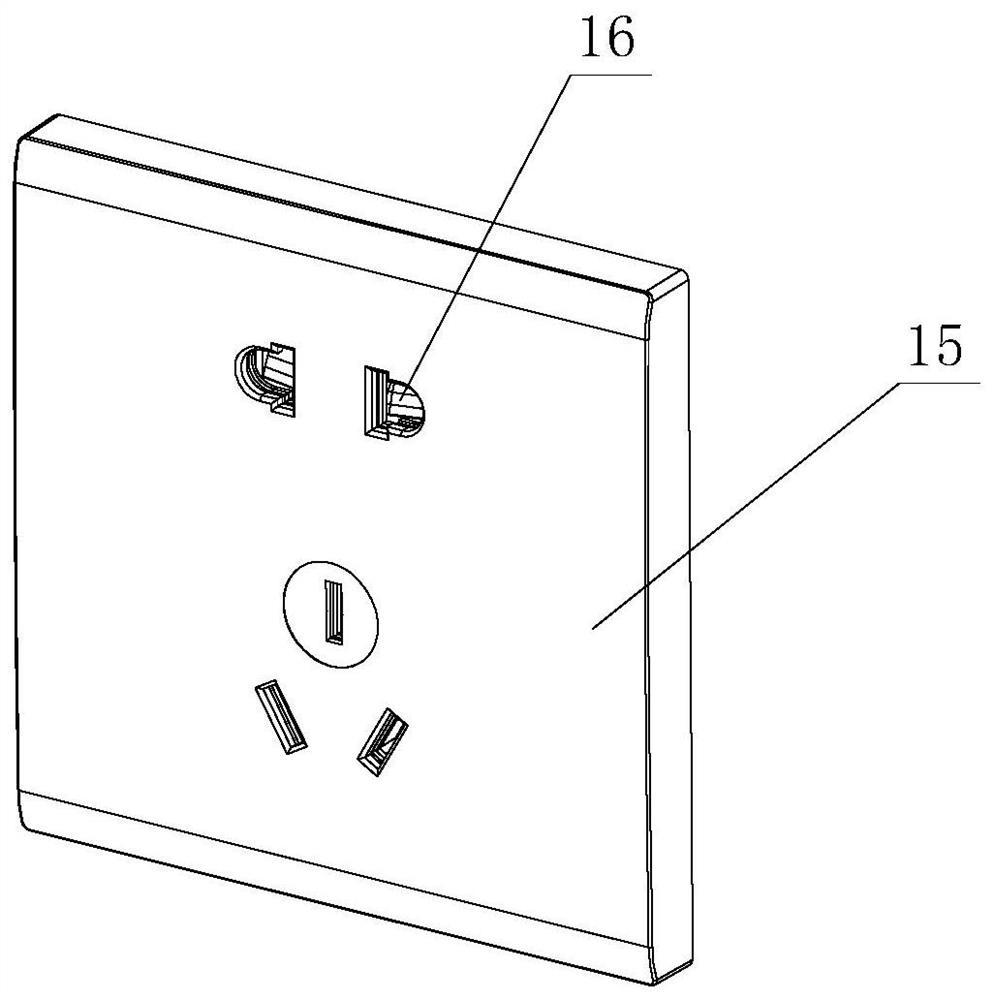

[0044] see Figure 1-Figure 14 , the single-pole anti-insert socket includes a base 1, a panel 12, a slider 2 and an electrode socket 4 are arranged on the base 1; an assembly cavity 13 is provided on the panel 12, and a positioning protrusion 21 is provided on the assembly cavity 13 The slider 2 is arranged on the assembly cavity 13, and a sliding part 8 is arranged on it, and the two sides of the slider 2 are respectively provided with a driving slope 3; the guide part 5 is provided with a sliding fitting part 9, and the sliding fitting Corresponding electrode sockets 4 on both sides of the upper part of the part 9 are respectively provided with notches 6 , and the notches 6 on both sides are respectively provided with positioning steps 7 .

[0045] The slider 2 slides on the sliding fitting part 9 through the sliding part 8 in anti-deflection mode w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com