Spline connecting structure for rear hub and rear flywheel of field bicycle

A technology of connecting structure and rear flywheel, applied in the direction of wheel hub, vehicle parts, transportation and packaging, etc., can solve the problem of slip wire and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

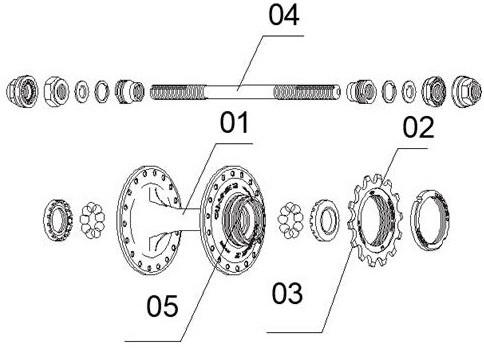

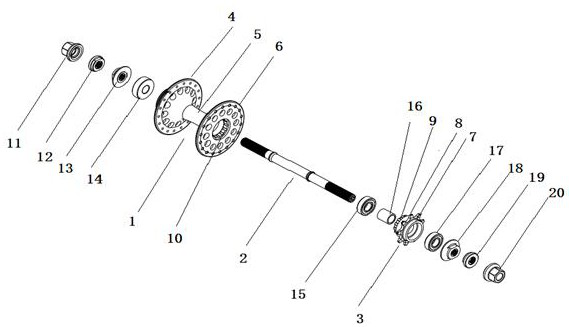

[0030] A spline connection structure between the rear hub and the rear flywheel of a track bicycle according to the present invention, please refer to Figure 1 to Figure 3 , the track bicycle includes a rear hub 1, a shaft 2 and a rear flywheel 3, the rear hub 1 and the rear flywheel 3 are sleeved on the shaft 2, and the two ends of the shaft 2 pass through a left nut 11 and a right nut 20 Fixed on the track bicycle frame, the rear hub 2 and the rear flywheel 3 are connected by splines. Existing track bikes such as figure 1 As shown, the rear hub 01 and the rear flywheel 02 are fixedly connected by threading. This connection method has the following problems. First, the rear hub 01 needs to be equipped with a rear adapter 05, and the adapter 05 is provided with threads. Then the adapter seat 05 is screwed into and fixedly connected with the rear flywheel 02, that is, the rear hub 01 is screwed into and fixedly connected with the rear flywheel 02. The setting of the adapter ...

Embodiment 2

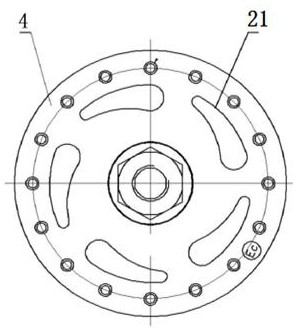

[0035] In this embodiment, the same technical features as in Embodiment 1 will not be repeated. The difference between this embodiment and Embodiment 1 is: a spline connection structure between the rear hub and the rear flywheel of a track bicycle of the present invention. Please refer to Figure 1 to Figure 2 , the rear hub 1 includes a front hub face 4, a hub shaft 5 and a rear hub face 6, the front hub face 4, hub shaft 5 and rear hub face 6 are integrally formed, and the front hub face 4 is fixed to one end of the hub shaft 5, The rear hub face 6 is fixed on the hub shaft 5, the part of the hub shaft 5 in front of the rear hub face 6 is the other end of the hub shaft 5, and an external spline 9 is arranged on the outer surface of the other end of the hub shaft 5, so that The other end of the hub shaft 5 is splined to the rear flywheel 3. The above structure specifically limits the spline structure of the rear hub 2 . Different from Embodiment 1, in this embodiment, an ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com