Noise reduction device for on-site maintenance of gas turbine

A gas turbine, on-site maintenance technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of noise reduction, large on-site space, and large impact, and achieve the effects of convenient implementation, simple structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

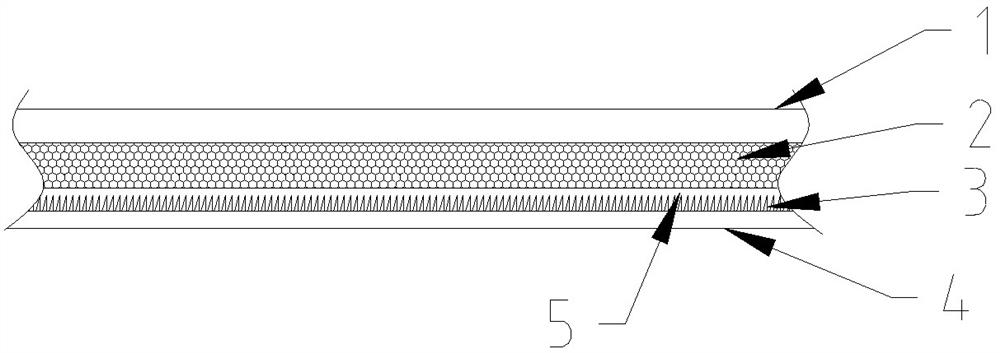

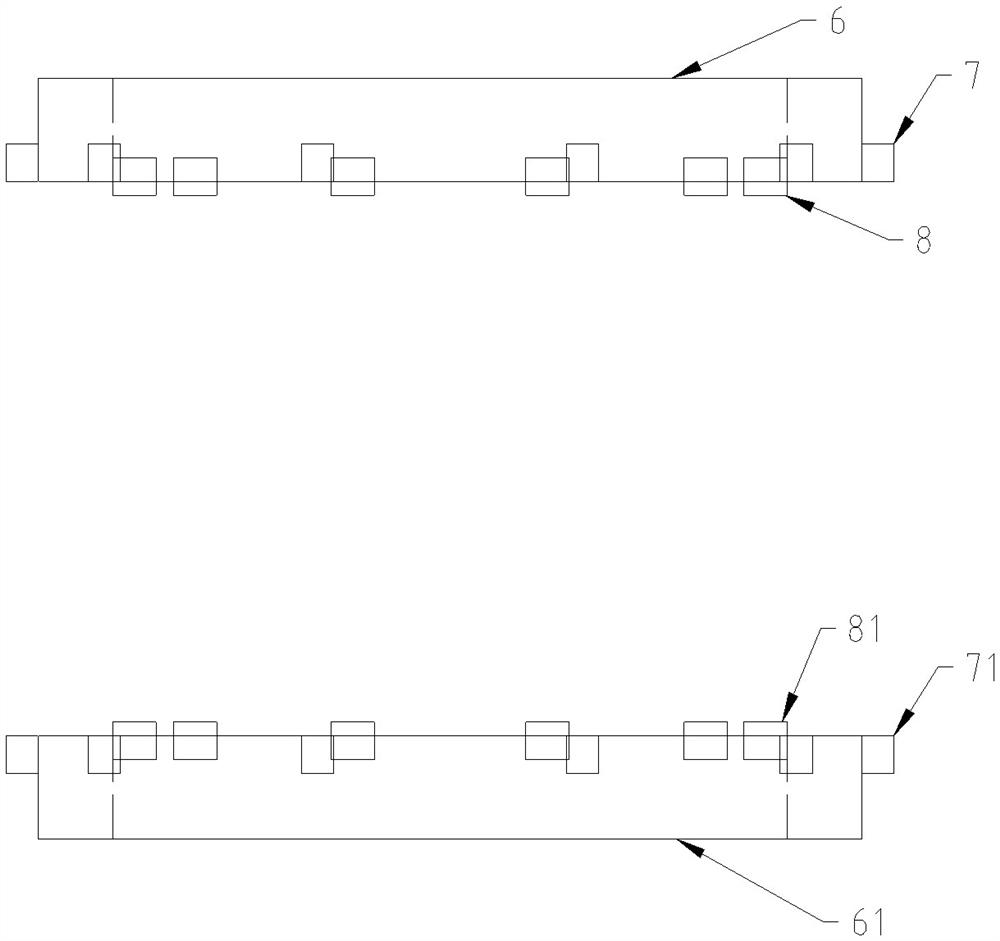

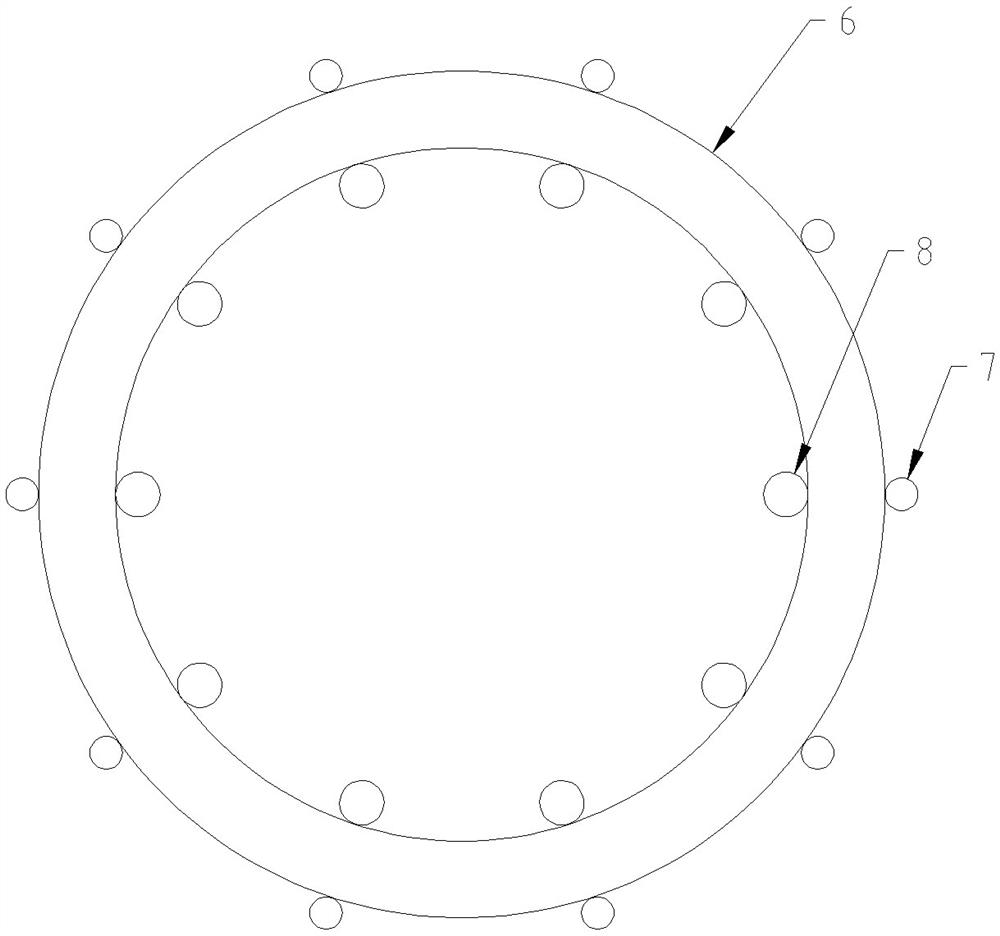

[0026] like Figure 1-4 The shown noise reduction device for on-site maintenance of a gas turbine includes a noise reduction blanket, the noise reduction blanket is arranged on the outer surface of the noise source, and the noise reduction blanket at least includes a gas-liquid mixing layer 1, a honeycomb layer 2, a vibration-absorbing Column 3, flexible layer 4, damping layer 5, the flexible layer 4 is the contact surface between the noise reduction blanket and the outer surface of the noise source, the flexible layer 4, the damping layer 5, the honeycomb layer 2, and the gas-liquid mixing layer 1 in sequence Arranged adjacently, the damping layer 5 is provided with a vibration-absorbing column 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com