Battery lock and locking method

A battery lock and battery technology, which is applied in charging stations, electric vehicles, transportation and packaging, etc., can solve problems such as failure of connection parts to rotate, failure of battery lock, locking and unlocking, etc., and achieve the effect of precise rotation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Taking an electric truck as an example, the battery box is placed on the vehicle body of the electric truck. In order to prevent the battery box from moving on the vehicle body, a battery lock needs to be used to lock the battery box to the vehicle body. Existing battery locks generally screw the screw into the nut to lock the battery box. Due to the possible deviation in the placement of the battery box on the car body, there may be inaccurate butt joints of the thread heads when the threads are screwed together. As a result, the threads are worn during the screwing process, and even stagnation occurs, which prevents normal screwing, resulting in failure of locking.

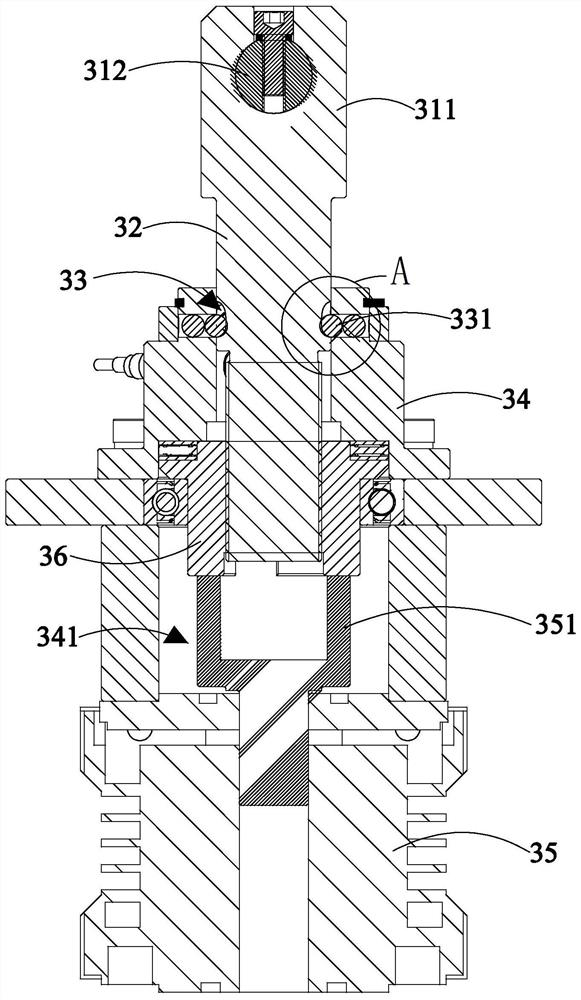

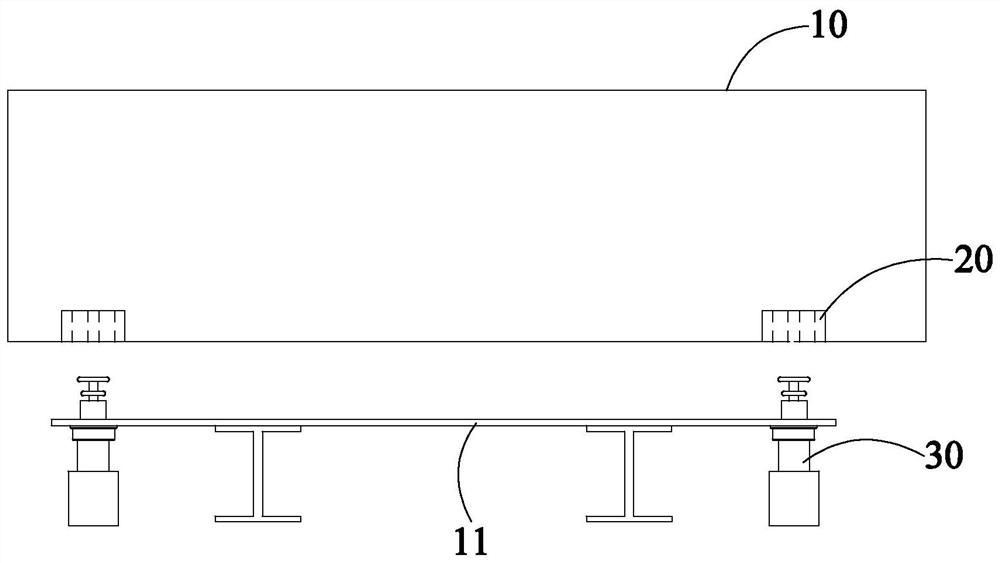

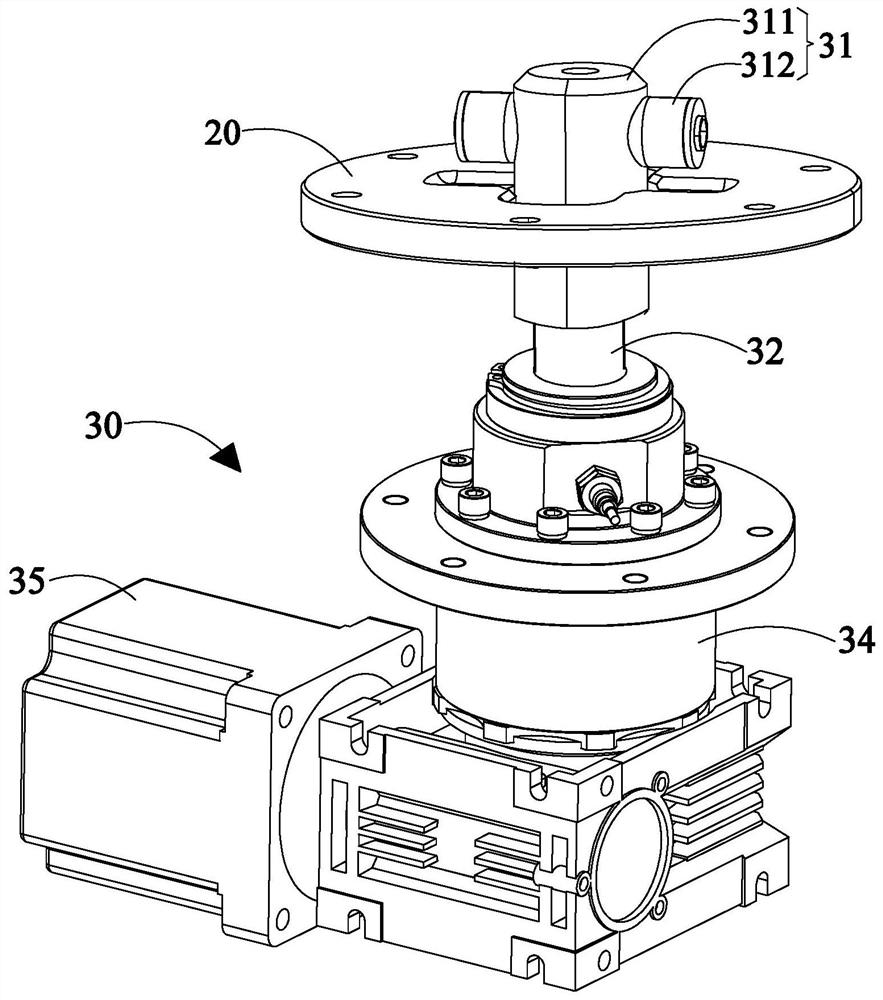

[0056] figure 1 It is a structural schematic diagram of Embodiment 1 of the battery lock in the power exchange system. Such as figure 1 As shown, the battery lock is used to lock the battery box 10 to the fixing part 11 , wherein the fixing part 11 can be a vehicle body, a battery rack or other parts fo...

Embodiment 2

[0083] Figure 9 It is a schematic structural diagram of the battery lock in Embodiment 2, Figure 10 It is a schematic sectional structure diagram of the battery lock in embodiment 2. Such as Figure 9 with Figure 10 As shown, the difference between Embodiment 2 and Embodiment 1 lies in that the positions of the first clamping part and the second clamping part of the clamping assembly are reversed. In Embodiment 2, the entry channel 21 of the first clamping part and the bearing Part is connected to the connecting piece 32 of the lock body 30 . The structure of the first clamping member is the same as that of Embodiment 1, and will not be repeated here. Correspondingly, the second clamping member of the clamping assembly (ie Figure 9 T-bar structure shown) is connected to the lock head 20. Wherein, the structure of the second clamping member is the same as that of Embodiment 1, and will not be repeated here.

[0084] In addition, the difference between Embodiment 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com