Test sample and tensile fixture for thermal simulation testing machine

A technology for testing samples and testing machines, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, reducing greenhouse gases, etc. And full contact, avoid high temperature, avoid the effect of fracture failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

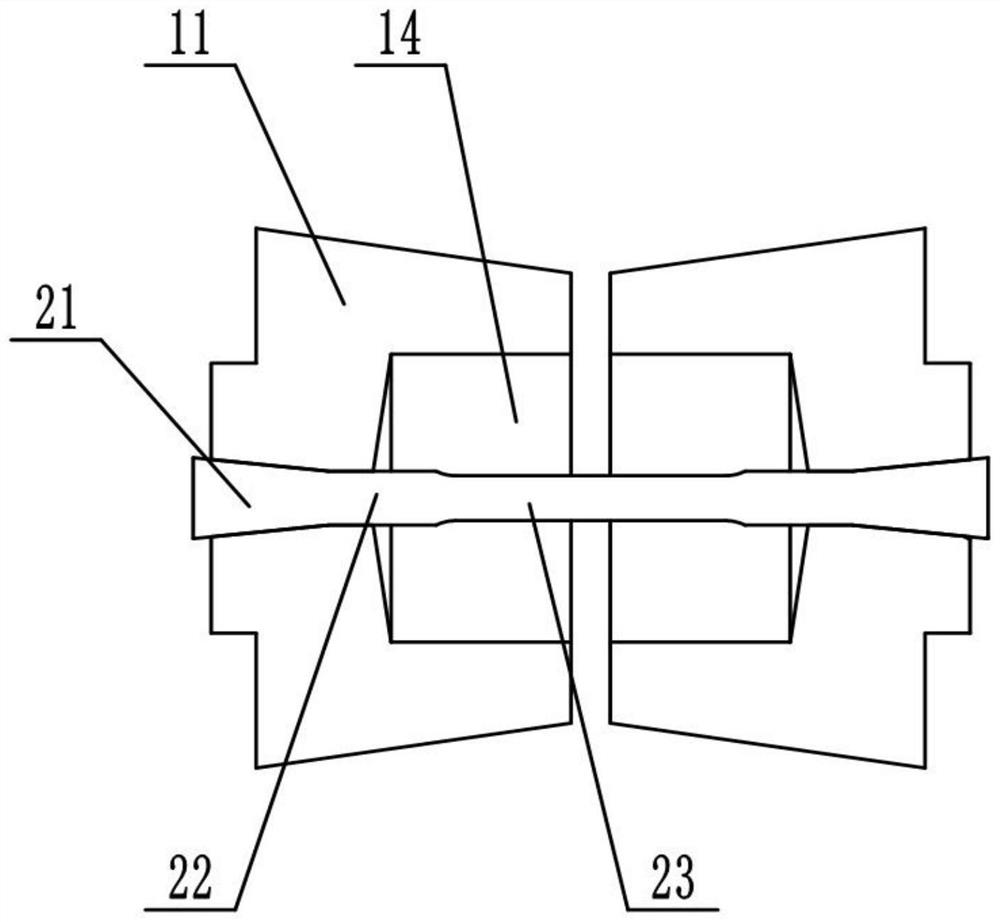

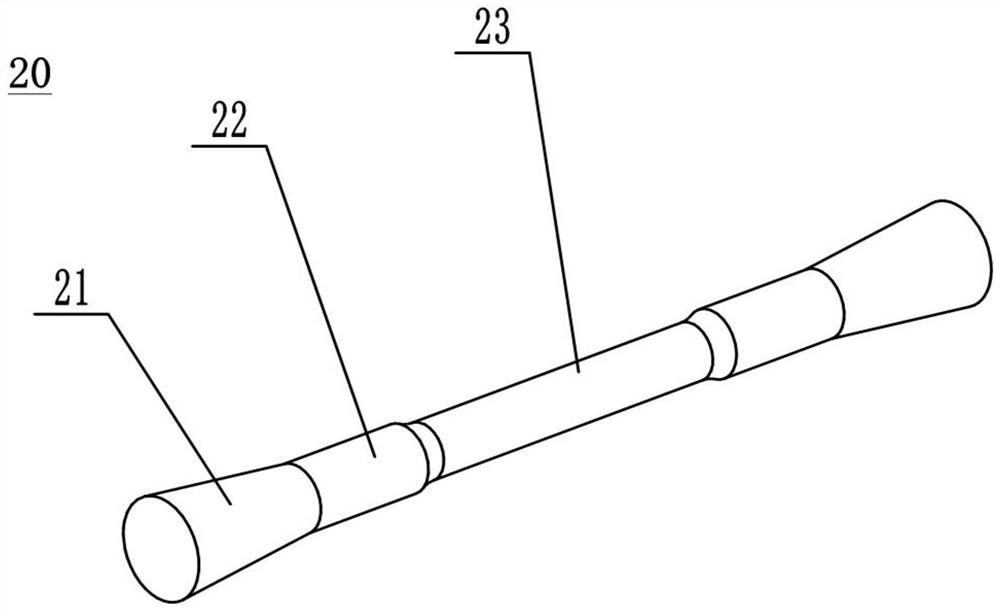

[0028] like Figure 1-Figure 3 As shown, the present embodiment provides a test sample 20 for a thermal simulation testing machine, including a parallel section 23 and two clamping transition sections, the two clamping transition sections are respectively fixed at both ends of the parallel section 23, and the clamping transition section It is used to be clamped by the clamp, and the clamp transition section can stretch the parallel section 23 under the drive of the clamp, and then perform a thermal tensile test on the test sample 20 for the thermal simulation testing machine. The two clamp transition sections The ends close to each other never touch the inner wall of the clamping piece, that is, the end of the clamping transition section close to the parallel section 23 protrudes into the uniform temperature cavity of the clamping piece, thereby ensuring that both ends of the parallel section 23 are located at the uniform temperature. In the cavity, to ensure the uniform heati...

Embodiment 2

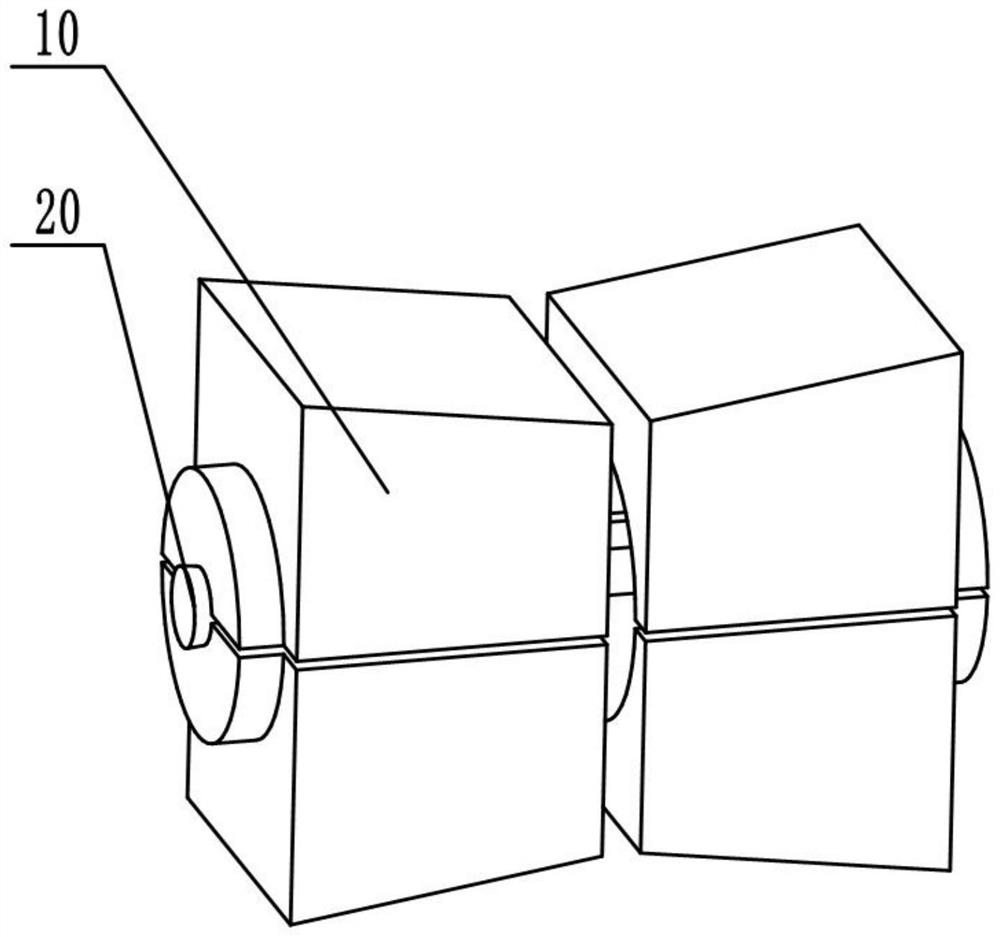

[0033] like Figure 1-Figure 2 as well as Figure 4 As shown, this embodiment provides a tensile fixture 10 for a thermal simulation testing machine, which is used to clamp the test sample 20 for a thermal simulation testing machine in Embodiment 1, including two sets of clamps, two sets of clamps They are respectively used to clamp the two clamping transition sections, and the two sets of clamping pieces are respectively used to electrically connect the positive pole and the negative pole of the thermal simulation testing machine to form a circuit through which the current passes, and provide current through the thermal simulation testing machine to realize utilization The resistance heating method heats the test sample 20 for the thermal simulation testing machine, and the two sets of clamps are used to clamp the test sample 20 for the thermal simulation testing machine under the action of the test end of the thermal simulation testing machine to provide a stable clamping fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com