Dovetail groove guide rail locking device and mounting and adjusting method

A dovetail groove and anti-loosening technology, applied in the field of guide rail transmission, can solve the problems of difficulty in adjusting the size of the friction force, potential safety hazards, affecting the transmission accuracy of the dovetail groove guide rail pair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

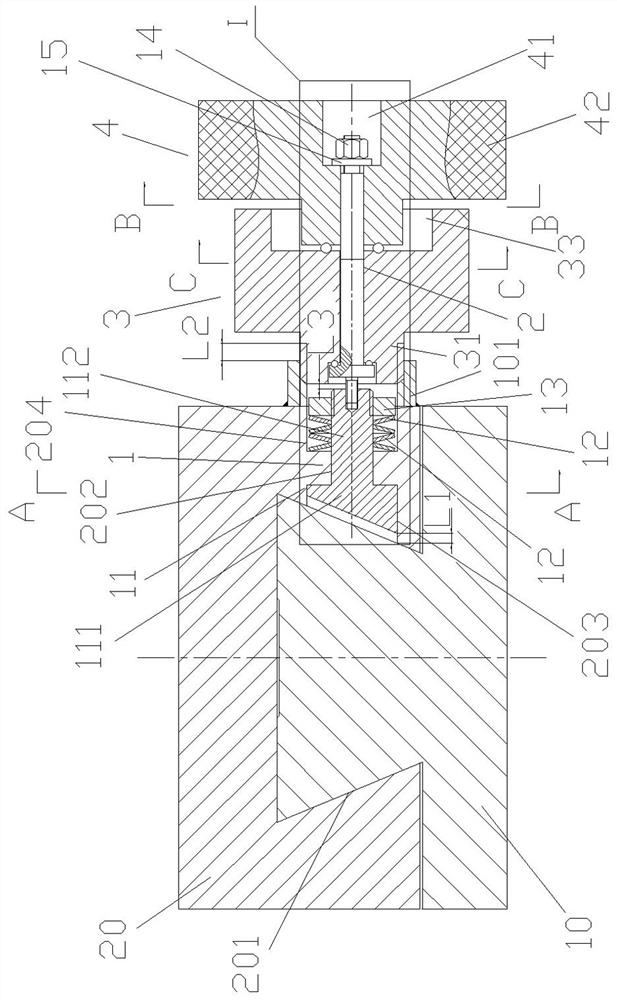

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

[0024] In the description of the present invention, terms such as "upper", "lower", "left", "right", "front", "rear", etc. indicating directions are based on the directions shown in the drawings, or are merely for the purpose of simplifying the description. , rather than indicating or implying that Ben must have a particular orientation.

[0025] Such as figure 1 As shown, the installation type of the dovetail guide rail pair in this embodiment is the type under the dovetail block 20 on the dovetail body 10, and the present invention can also be used for the installation type under the dovetail body 10 on the dovetail block 20.

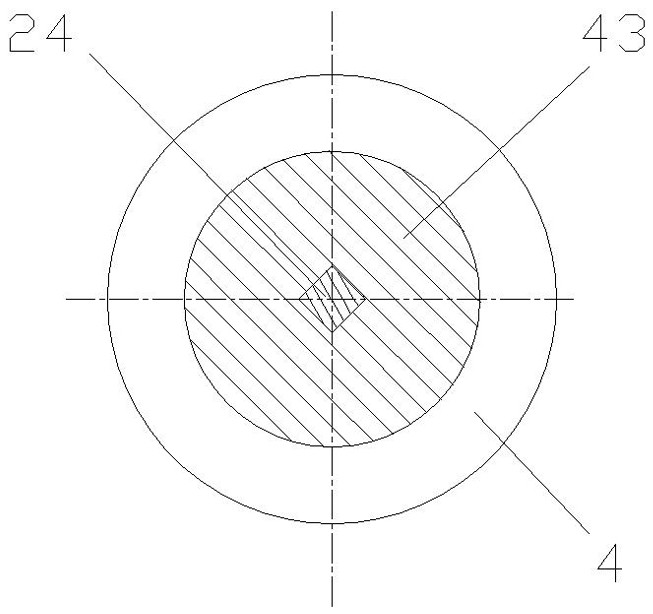

[0026] Such as Figure 1 to Figure 5 As shown, this embodiment includes a piston mechanism 1, a rotating shaft 2, a coarse adjustment nut 3 and a fine adjustment hand wheel 4 installed inside and outside one side of the dovetail tank body 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com