Door lock structure and garbage compression box

A technology of door lock structure and locking structure, which is applied in the direction of trash cans, garbage collection, household appliances, etc., and can solve the problem of difficulty in meeting the locking strength and sealing requirements of the front door and the box body, troublesome operation, lock tongue and lock body Weak strength and other problems, to achieve the effect of improving reliability and sealing, saving labor and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

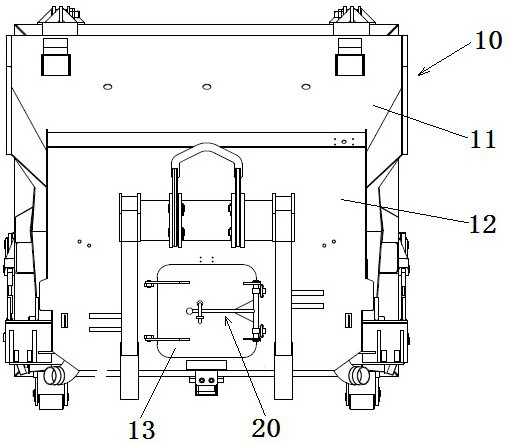

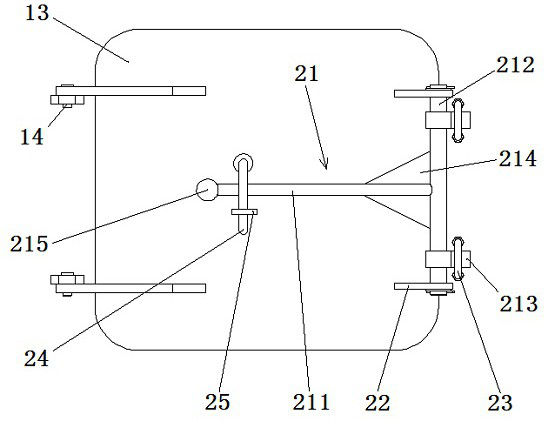

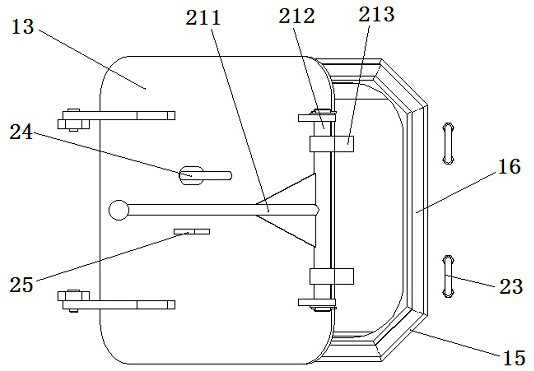

[0075] Embodiment 1 of the garbage compression box in the present invention: the garbage compression box of this embodiment is placed in the garbage transfer station for use, and can be lifted by the hook-arm truck and moved with the hook-arm truck. like figure 1 As shown, the garbage compression box 10 includes a box body 11 for accommodating garbage. The top of the box body is provided with an entrance for the garbage to enter the box body. to compress. At the end of the shovel movement stroke, there is an outlet for the garbage to be discharged from the box. The hydraulic system driving the shovel movement in the body is inspected and maintained. The side wall 12 corresponding to the inspection port is hinged with a front door 13 for blocking the inspection port through a hinge 14. The part of the side wall 12 close to the front door 13 forms a joint with the front door 13. The door panel fits the door frame.

[0076] Since the front door 13 needs to ensure good sealing,...

Embodiment 2

[0090] Embodiment 2 of the garbage compression box in the present invention: the difference from the above embodiments is that in this embodiment, the rotation axis of the hinge seat in the door lock structure is perpendicular to the rotation axis of the front door, specifically, the left side of the front door It is hinged with the box body, and the hinge axis extends in the up and down direction, and hinge seats are arranged on the upper and lower sides of the front door, and a lever is installed in each of the hinge seats on the upper and lower sides, and the lever extends in the up and down direction, and the front door is simultaneously controlled by two There are two sets of the first locking structure and the second locking structure corresponding to the lever, and the second locking structure is respectively installed on the side wall of the box at the position above and below the front door. place. When locking the front door, it is necessary to simultaneously block a...

Embodiment 3

[0091] Embodiment 3 of the garbage compression box in the present invention: the difference from the above embodiment is that in this embodiment, the lever includes a rotating shaft that cooperates with the hinge seat, and the outer peripheral surface of the rotating shaft is connected with a rod body that overhangs from the back. The rod body facing the first locking structure is the operation unlocking end of the lever, and the rod body extending toward the second locking structure is the hooking locking end of the lever. At this time, it is not limited to adopting a plurality of dead bolts in the lever as the lever. Scheme for hooking the locking end.

[0092] Embodiment 4 of the garbage compression box in the present invention: the difference from the above-mentioned embodiment is that in this embodiment, the lever includes a rotating shaft that cooperates with the hinge seat, and the rotating shaft is provided with a long rod as an operation unlocking end, and as a hook D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com