Non-welding type piezoelectric vibrator connecting device and ultrasonic flow detection device adopting same

A technology for piezoelectric vibrators and connecting devices, which is applied in the directions of measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc. It can solve problems such as difficult replacement of piezoelectric vibrators, achieve good contact contact, improve economy and Environmentally friendly and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] refer to Figure 5-8, this embodiment provides a non-welded piezoelectric vibrator connection device, including a screw cap 8, a sleeve 12, and a piezoelectric vibrator seat 14;

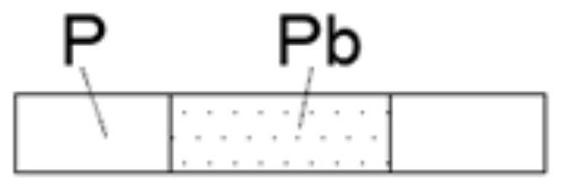

[0048] The screw cap 8 is provided with a screw cap inner cavity 81, and the screw cap inner cavity 81 is provided with a screw cap inner cavity stepped surface 82, and one end of the sleeve 12 is inserted into the screw cap inner cavity 81 and is offset against the screw cap inner cavity stepped surface 82 , the other end of the casing 12 is fixedly connected to the piezoelectric vibrator seat 14;

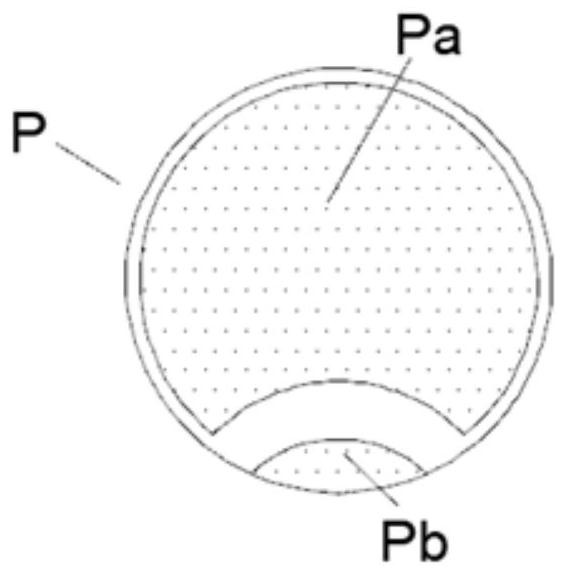

[0049] The piezoelectric vibrator base 14 is provided with an annular cavity 140, which is used for embedded installation of the piezoelectric vibrator 100, and the annular cavity 140 is provided with a stepped surface 143 of the annular cavity, through which the stepped surface 143 of the annular cavity is offset against the piezoelectric vibrator 100. Limiting the piezoelectric vibrator 100;

...

Embodiment 2

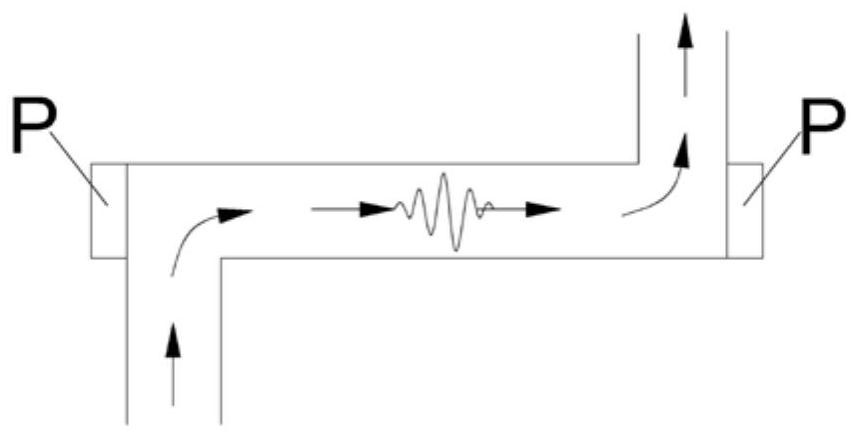

[0065] refer to Figure 9 , this embodiment provides an ultrasonic flow detection device, including the non-welded piezoelectric vibrator connection device described in Embodiment 1, and also includes a sensor housing 120, the sensor housing 120 has a hollow flow path for the fluid medium circulation, the two sides of the sensor housing 120 are oppositely provided with a first installation pipe 123 and a second installation pipe 124, and a non-welded piezoelectric vibrator connection device is respectively installed in the first installation pipe 123 and the second installation pipe 124; The piezoelectric vibrator connection device presses the piezoelectric vibrator 100 on the wall of the sensor housing 120, and the coupling agent is coated between the piezoelectric vibrator 100 and the wall of the sensor housing 120.

[0066] Specifically, external threads are provided on the outside of the screw cap 8, and internal threads matching the external threads are provided in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com