Pipeline type phase change heat reservoir with replaceable heat storage units and working method of pipeline type phase change heat reservoir

A heat storage and pipeline-type technology, which is applied in the field of pipeline-type phase change heat storage, can solve the problems of wide application scenarios, difficult operation, complex structure, etc., and achieve the goals of wide application scenarios, reduced ground space occupation, and reduced construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

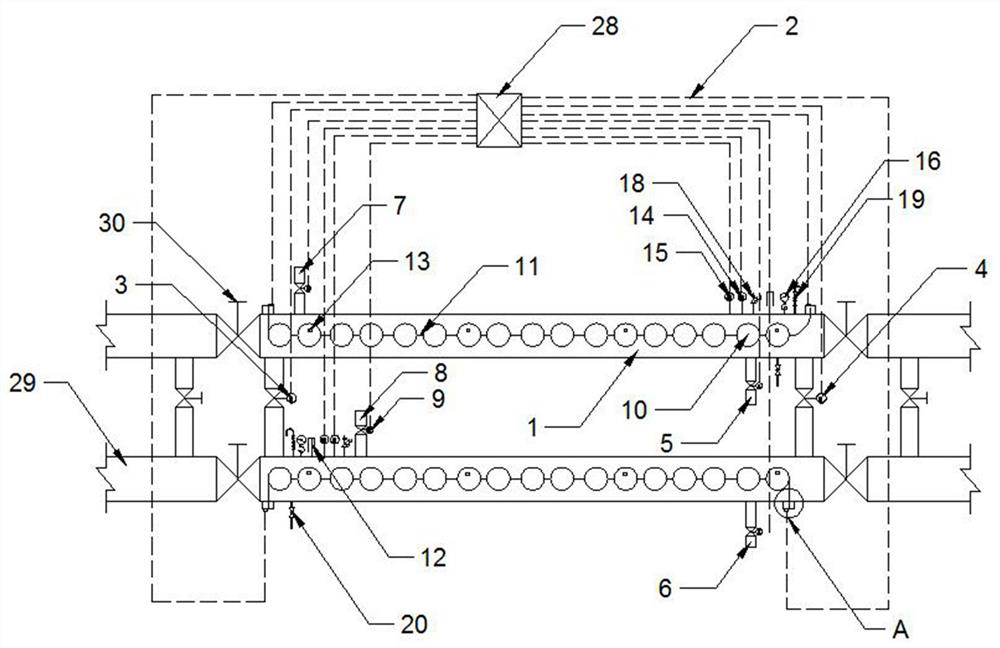

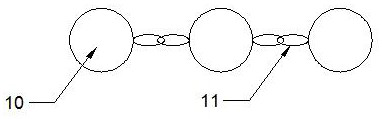

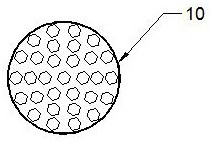

[0033] Embodiment 1, a pipe-type phase-change heat storage with a replaceable heat storage unit, installed on the delivery pipeline 1 of the heat supply network, such as figure 1As shown, it includes a receiving control unit, a heat storage and release unit, a heat storage and release valve assembly, and an induction unit. The reception control unit is connected to the heat storage and release unit, the heat storage and release valve assembly, and the induction unit through the control line 2 , the heat storage and release unit is set in the delivery pipeline 1 and the heat storage and release unit is connected to the delivery pipeline 1 through a movable connection assembly, the heat storage and release valve assembly and the induction unit are both arranged on the delivery pipeline 1 and the heat storage and release The valve assembly matches the heat storage and release unit. When heat storage is required, the heat source end is connected to the heat storage and release val...

Embodiment 2

[0052] Example 2, such as Figure 6 As shown, a working method of a pipe-type phase-change heat storage with a replaceable heat storage unit, using the pipe-type phase-change heat storage with a replaceable heat storage unit in Example 1 for heat storage and exchange for the user end heat, including the following steps:

[0053] S1. Start the heat storage procedure. The heat storage inlet 5 and the heat storage outlet 6 are connected to the heat source. The construction personnel open the on-off valve 9 of the heat storage inlet 5 and the on-off valve 9 of the heat storage outlet 6 through the receiving controller 27. The first connecting valve 3 closes the second connecting valve 4, the low-temperature water in the delivery pipeline 1 continuously enters the heat source end for heat exchange and then returns to the delivery pipeline 1, and the high-temperature water after heat exchange exchanges heat with the heat storage and heat release unit to store the heat In the heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com