Feeding mechanism and feeding method of double-faced adhesive tape attaching machine for touch screen

A technology of feeding mechanism and double-sided tape, applied in thin material handling, object supply, winding strips, etc., can solve the problems of suction cup assembly not being able to suck, sucking unstable, reducing work efficiency and yield rate, etc. The effect of adhesion, reducing the sticking area, improving work efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

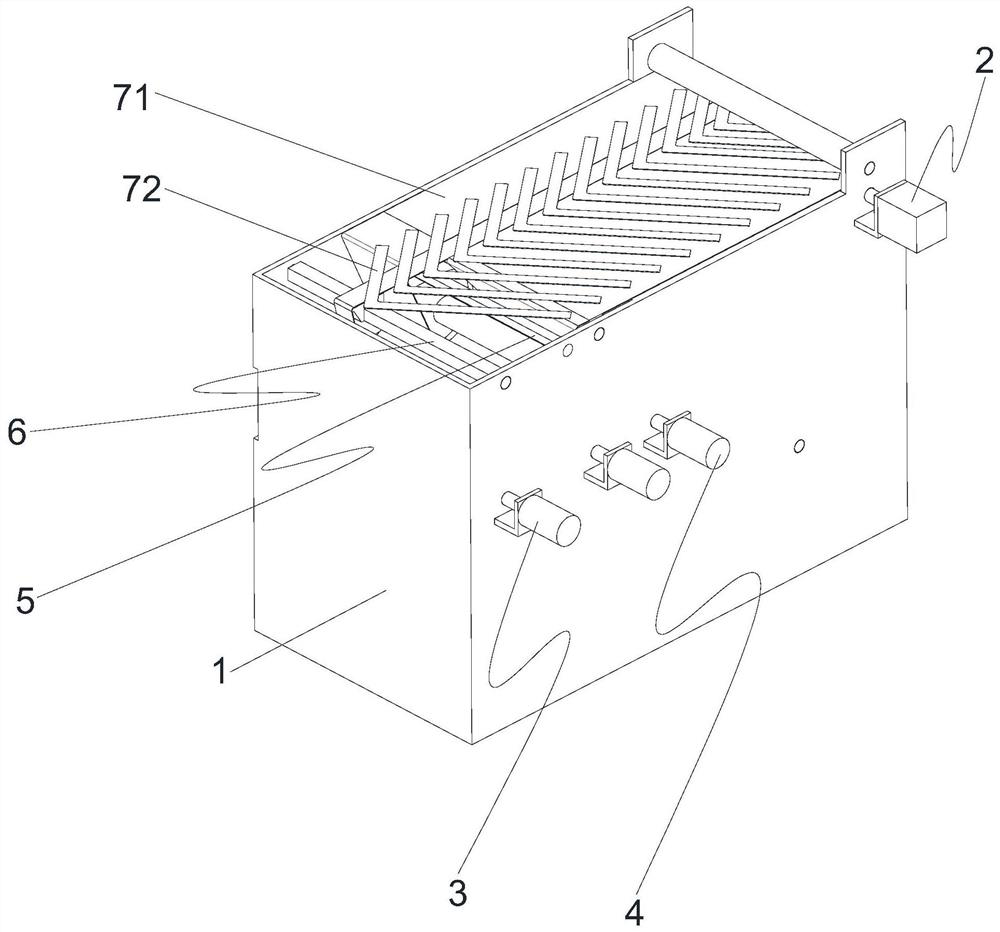

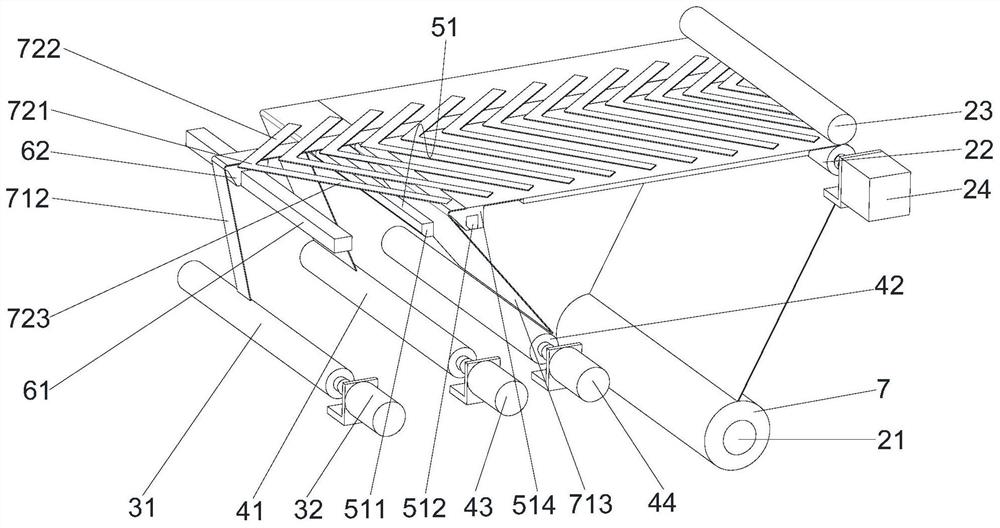

[0034] Such as Figure 1-Figure 3 As shown, a feeding mechanism of a double-sided adhesive laminating machine for a touch screen includes a frame 1, and an unwinding assembly 2, a first roll assembly 3, and a second roll assembly respectively arranged on the frame 1 Assembly 4, first guide assembly 5 and second guide assembly 6; the second roll paper assembly and the first roll paper assembly are arranged in front of the unwinding assembly 2 in turn; the first guide assembly 5 and the second guide assembly 6 are arranged in turn The front of the unwinding assembly 2 is correspondingly matched with the second roll assembly and the first roll assembly 3 respectively. Preferably, both the first guide assembly 5 and the second guide assembly 6 are located above the first paper roll assembly 3 and the second paper roll assembly 4 . When in use, the unwinding assembly 2 is used to install a film 7 and control the unwinding of the film 7; the film 7 includes a release paper 71 and a...

Embodiment 2

[0045] Under the same idea, the present invention also provides a feeding method for a double-sided adhesive laminating machine for a touch screen, comprising the following steps:

[0046] (1) The film is installed on the unwinding assembly, the film includes a release paper and an L-shaped double-sided tape pasted on the release paper; the release paper includes the first paper distributed sequentially along its width direction section, the second paper section and the third paper section; the L-shaped double-sided adhesive tape includes an angle section which is arranged forward and fits the second paper section and is respectively arranged at both ends of the angle section and a first extension section and a second extension section attached to the first paper section and the third paper section respectively;

[0047] (2) Connect the first paper section and the third paper section to the first guide assembly and then respectively connect them to the second roll paper assemb...

Embodiment 3

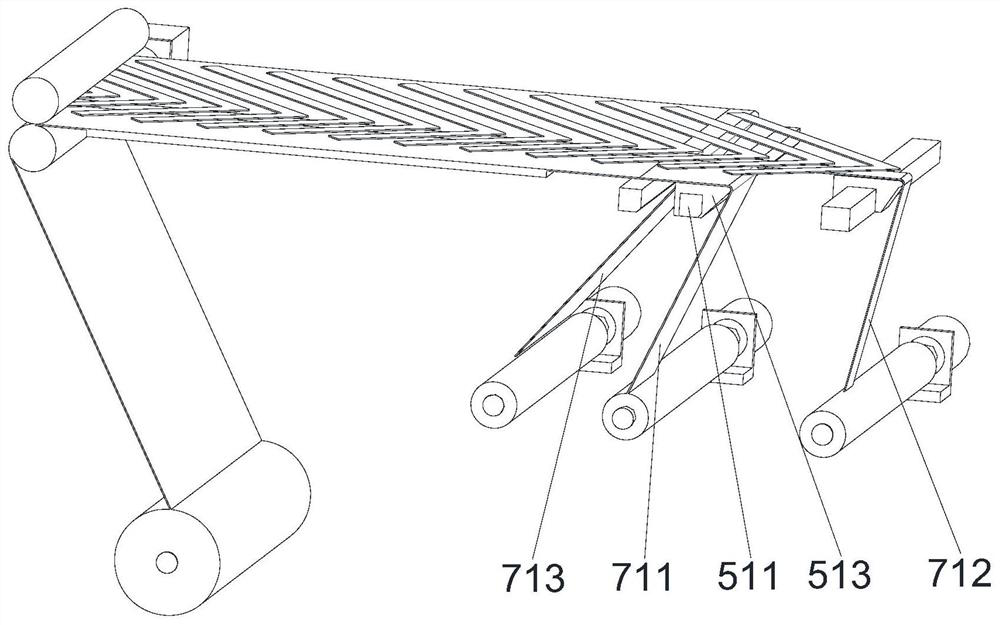

[0055] Such as Figure 4-Figure 6 as shown,

[0056] The difference between this embodiment and Embodiment 1 is that, in this embodiment, the first guide assembly 5 only includes the first guide beam 51, and the second guide assembly 6 only includes the second guide beam 61, and the first Both the first guide beam 51 and the second guide beam 61 are cylindrical, and the first guide beam 51 and the second guide beam 61 are horizontally arranged in parallel. The first paper segment 711 and the third paper segment 713 are respectively connected to the first guide beam 51 and then respectively connected to the second roll paper assembly 4, while the second paper segment 712 is connected to the second guide beam 61 and then connected to the second roll assembly 4 A roll of paper assembly 3 on. Of course, the feeding mechanism in this embodiment also has other structures, but they are all the same as those in Embodiment 1, and will not be described in detail here. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com