Integrated inductor automatic feeding and paint stripping optical screening machine

A technology of automatic feeding and screening machine, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of inconvenient production and processing, rising process costs, affecting production efficiency, etc., to save costs and shorten the process chain , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

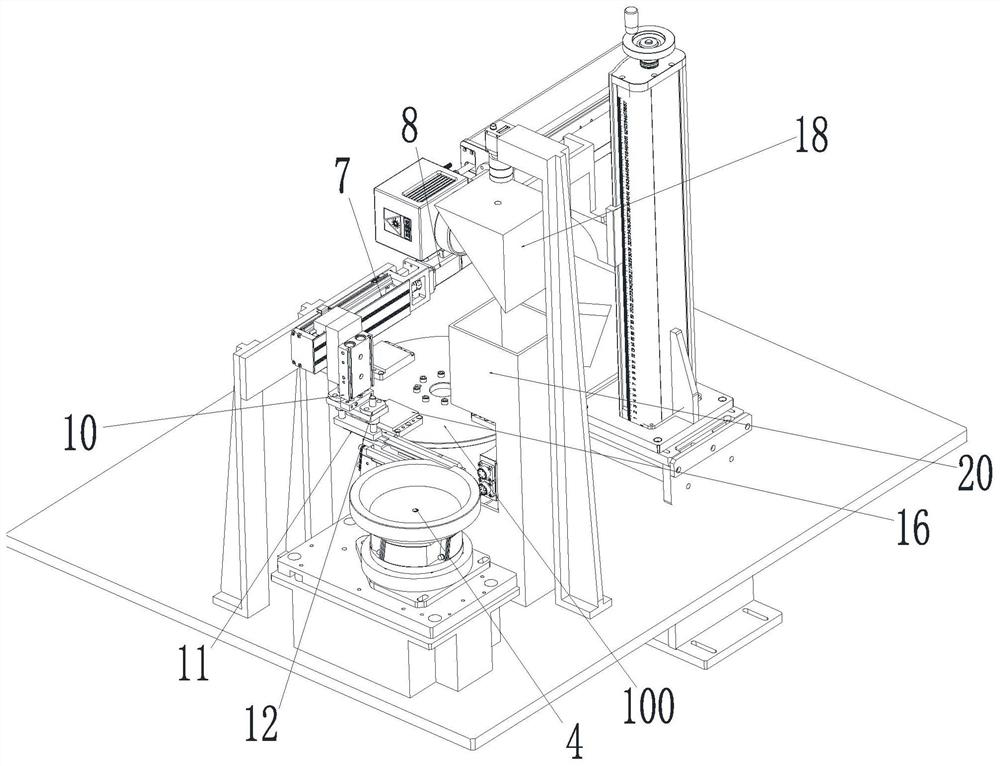

[0031] Please refer to the attached Figure 1-5 , an integrated inductance automatic feeding and paint stripping optical screening machine according to the present invention, comprising a first turntable 100, a feeding mechanism 200, an inductance paint stripping assembly 300, a product push guide mechanism 400, a second turntable 500, a visual screening The detection system 600 and the material distribution and receiving mechanism 700; the first turntable 100 has a plurality of rotatable jigs 16 for carrying inductance; the feeding mechanism 200 is arranged on one side of the first turntable, It is used to feed the inductance to the jig 16 of the first turntable 100 in a row; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com