Auxiliary material adding equipment for food production

A technology of using auxiliary materials and equipment, which is applied in the field of adding auxiliary materials to equipment for food production. It can solve problems such as unsmooth discharge effect and hygiene problems, and achieve the effect of keeping clean, avoiding hygiene problems, and avoiding unsmooth discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

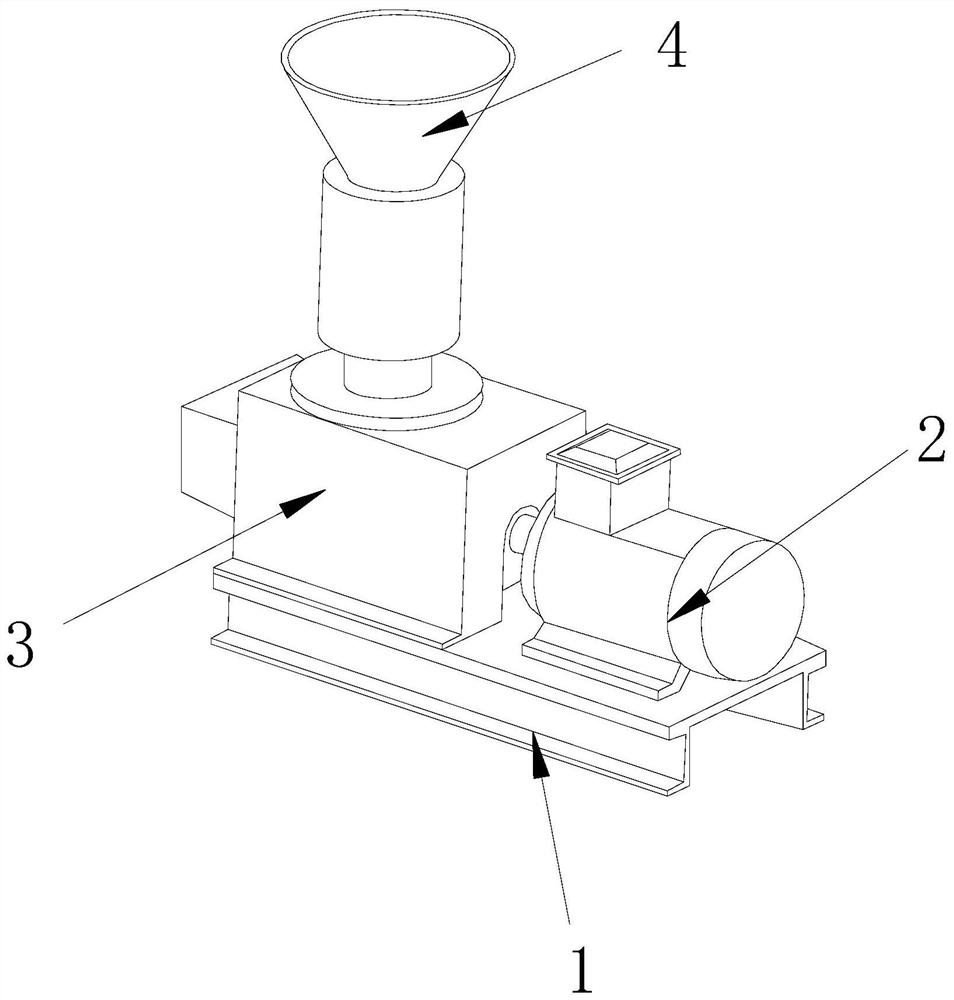

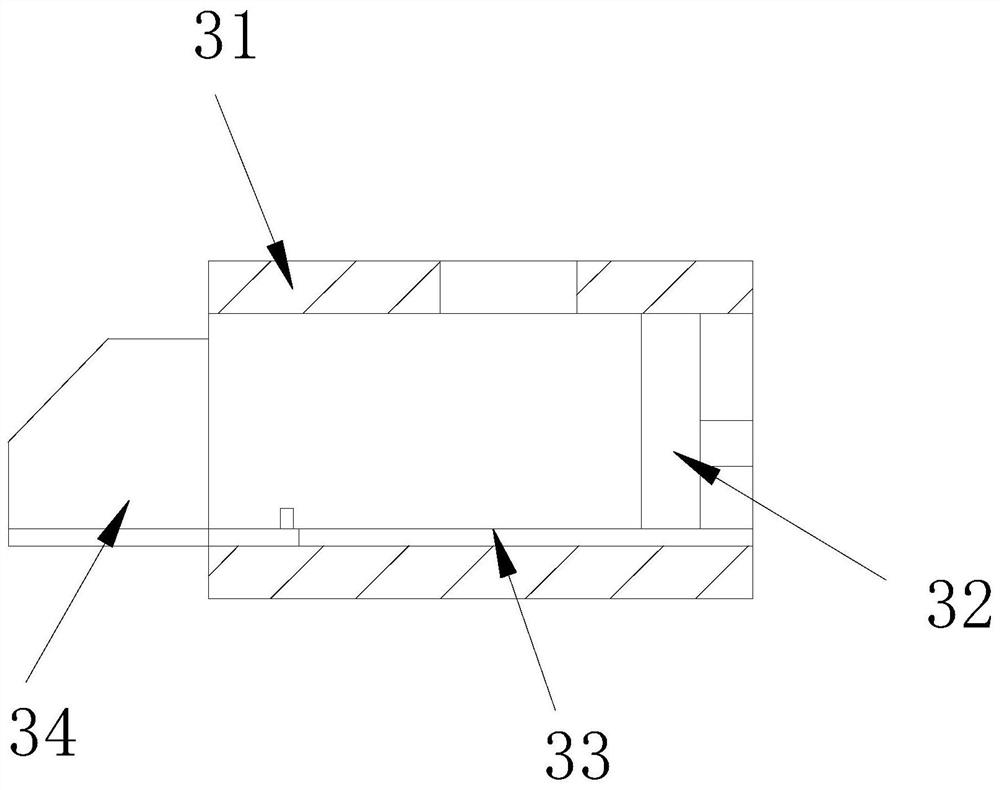

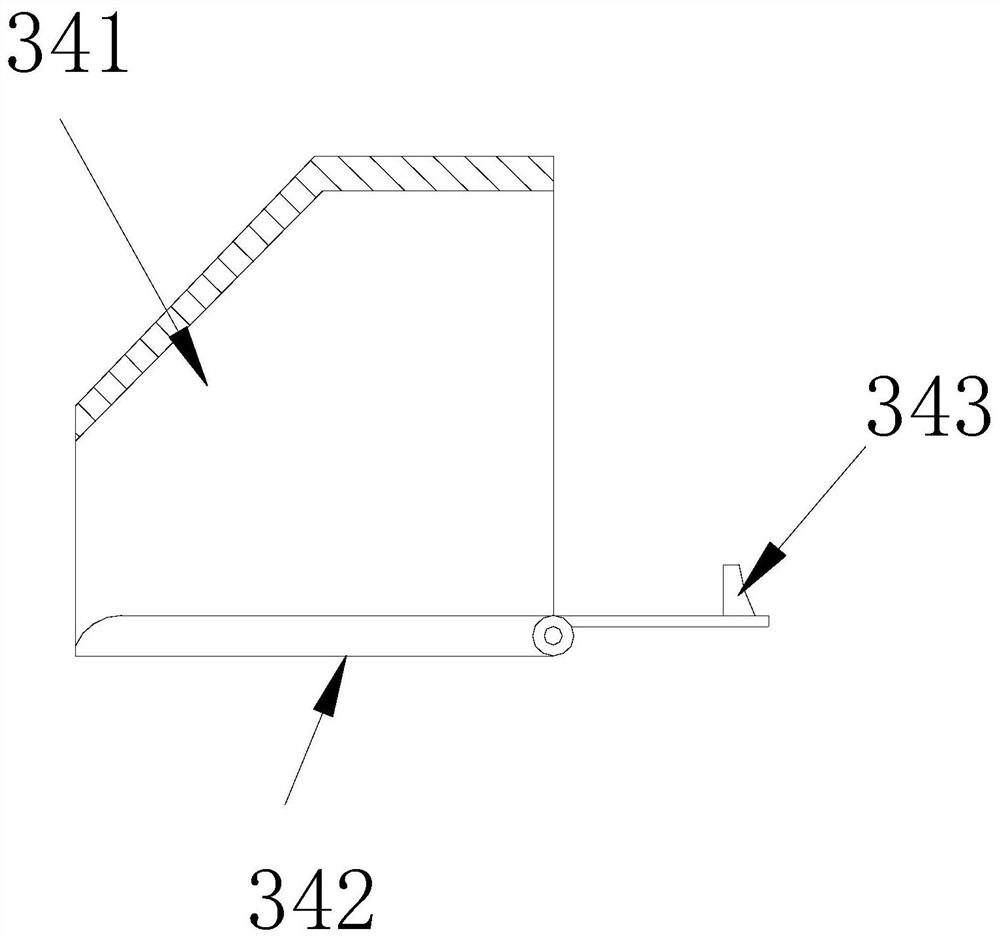

[0028] see Figure 1-Figure 6 , the specific embodiments of the present invention are as follows: a food production auxiliary material adding equipment, its structure includes a base 1, a pusher 2, an output device 3, and a bucket 4, the top surface of the base 1 is welded to the bottom surface of the pusher 2, and the The bottom surface of the output device 3 is welded to the top surface of the base 1, and the bottom surface of the adding bucket 4 and the top surface of the output device 3 are interconnected and embedded; the output device 3 includes a casing 31, a push plate 32, a placement plate 33, a discharge Bucket 34, the inner layer of the casing 31 is transitionally connected with the outer layer of the push plate 32, the bottom surface of the placement plate 33 is embedded and connected with the inner layer of the casing 31, and the right side of the discharge bucket 34 is embedded and connected with the left side of the casing 31. A control block is provided on the ...

Embodiment 2

[0035] see Figure 7-Figure 9 The specific embodiment of the present invention is as follows: the expansion head B4 includes a folding block B41, a push rod B42, a track head B43, and an outer expansion block B44, the inner layer of the folding block B41 is embedded and connected with the bottom surface of the push rod B42, and the track The bottom surface of the head B43 is embedded and connected to the top surface of the folding block B41, the bottom of the outer expansion block B44 is movably connected to the top surface of the track head B43, and the middle section of the folding block B41 is provided with an S-shaped through-groove structure, which is connected by an elastic sheet. It is beneficial to generate relative longitudinal displacement when swinging up, and avoid lateral deviation.

[0036] Wherein, the external expansion block B44 includes a pushing block C1, a blocking stack C2, a spreading handle C3, and a sliding wheel C4. The bottom surface of the pushing bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com