Satellite-borne flexible composite material shell surface deployable antenna device

A composite material and antenna device technology, which is applied to antennas, antennas, folded antennas and other directions suitable for movable objects, can solve the problem of reducing the number of back support ribs, and achieve reliable deployment process, high-precision shape retention capability, and storage. Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

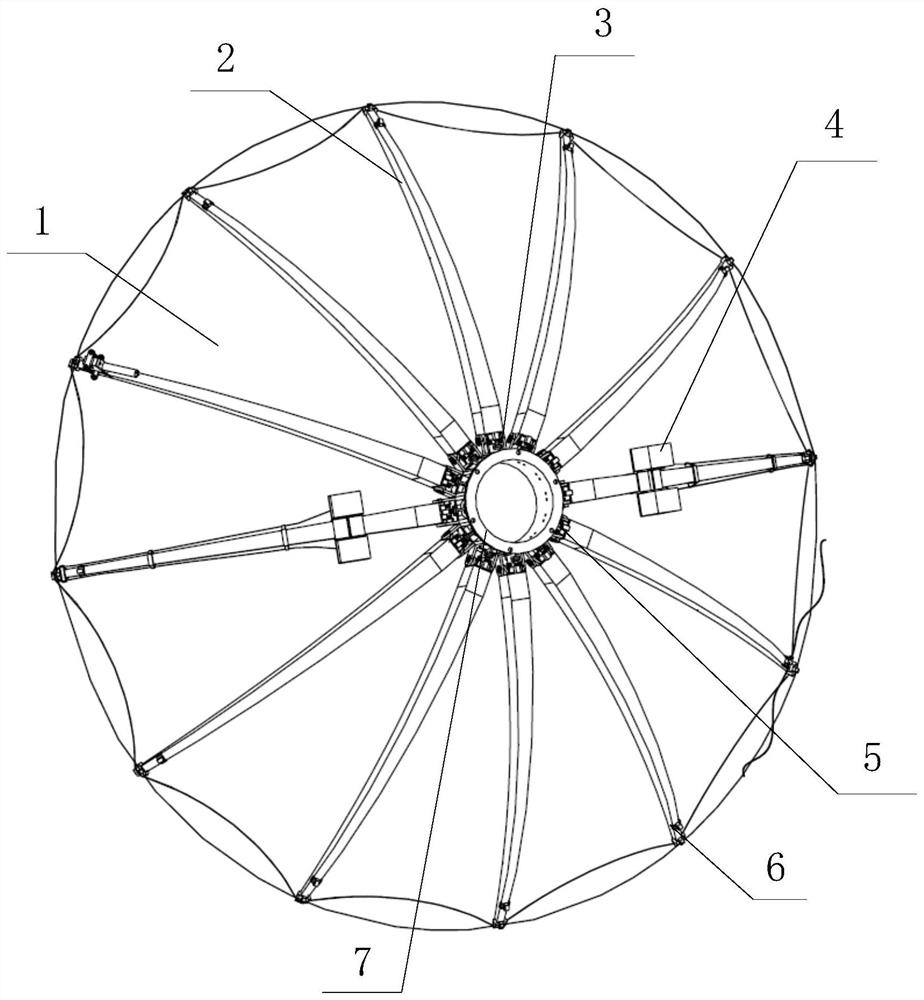

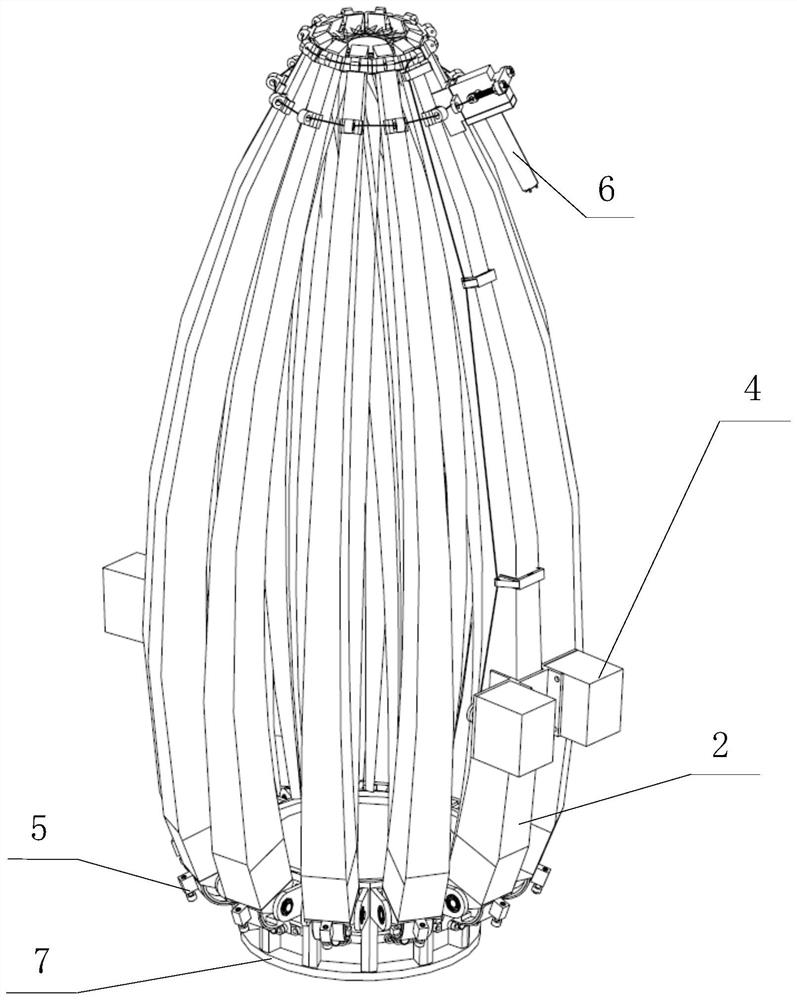

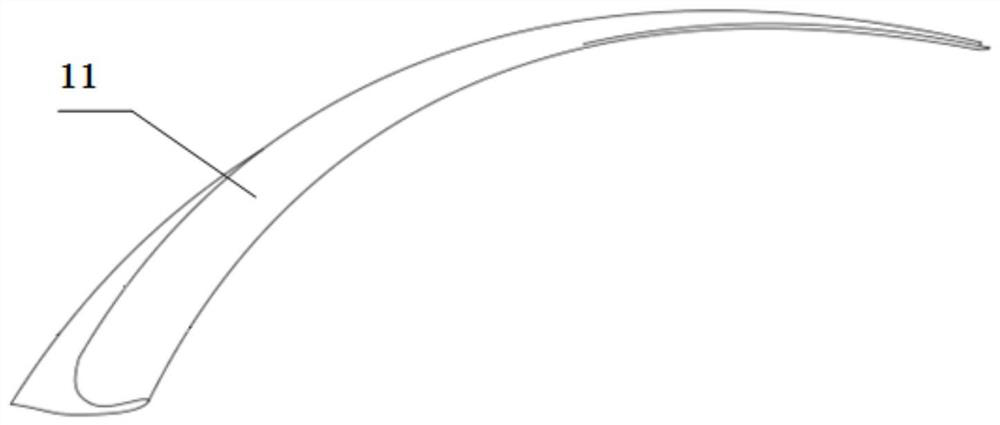

[0036] Such as figure 1 As shown, a space-borne flexible composite material shell surface deployable antenna device includes a flexible composite material shell surface 1, and N radial support ribs 2 with variable cross-sections arranged radially on the back of the flexible composite material shell surface 1 at equal angles. The constant moment hinge 3 at the starting end of the variable-section radial support rib 2, the deployment synchronization device 4 arranged in the middle of the variable-section radial support rib 2, and the expansion limit adjustment provided at the starting end of each variable-section radial support rib 2 Device 5, the locking and unlocking device 6 arranged at the end position of the radial support rib 2 with variable cross section and the annular center body 7 connected to the starting end of each radial support rib 2 with variable cross section; the synchronization device 4 and The locking and unlocking devices 6 are located on the back of the fle...

Embodiment 2

[0040] Such as figure 1 As shown, a space-borne flexible composite material shell surface deployable antenna device includes a flexible composite material shell surface 1, and N radial support ribs 2 with variable cross-sections arranged radially on the back of the flexible composite material shell surface 1 at equal angles. The constant moment hinge 3 at the starting end of the variable-section radial support rib 2, the deployment synchronization device 4 arranged in the middle of the variable-section radial support rib 2, and the expansion limit adjustment provided at the starting end of each variable-section radial support rib 2 Device 5, the locking and unlocking device 6 arranged at the end position of the radial support rib 2 with variable cross section and the annular center body 7 connected to the starting end of each radial support rib 2 with variable cross section; the synchronization device 4 and The locking and unlocking devices 6 are located on the back of the fle...

Embodiment 3

[0055] Such as figure 1 As shown, a space-borne flexible composite material shell can expand the working state form of the antenna device, which is the basic form of the present invention. It consists of a flexible composite material shell 1, a variable cross-section radial support rib 2, a constant moment hinge 3, Synchronization device 4, expansion limit adjustment device 5, locking and unlocking device 6, central body 7 constitute. The number of radial support ribs 2 with variable cross-sections is determined according to the shape and surface accuracy requirements and the storage volume after deployment. After the deployment is completed, the flexible composite material shell surface 1 is in an initial stress-free state, and is fixed to the radial support ribs 2 with variable cross-section by adhesive bonding. The radial support ribs 2 with variable cross-sections provide the mechanical interfaces of the unfolding constant moment hinge 3 , the synchronizing device 4 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com