Device for removing folds of cylindrical kraft paper battery through diagonal pressing

A kraft paper and cylindrical technology, which is applied in the field of diagonal pressing and unpacking kraft paper cylindrical battery wrinkle devices, can solve the problems of potential safety hazards, weakened battery insulation, easy entry of air, etc., to prevent air entry, facilitate handling, and seal Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

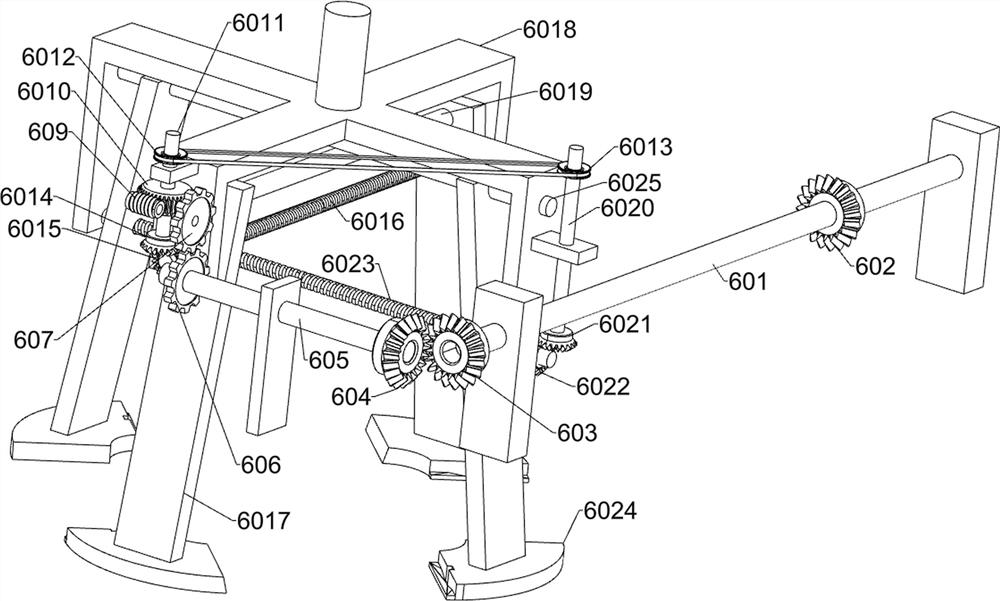

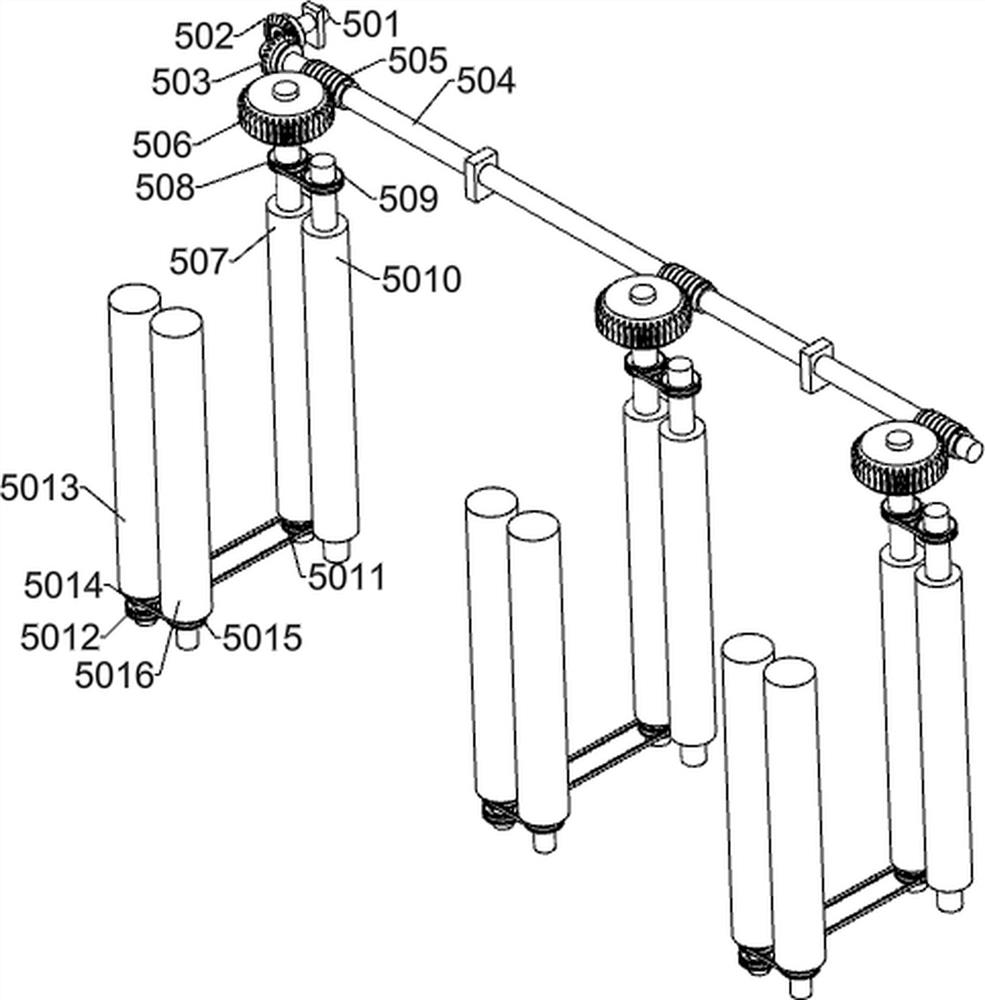

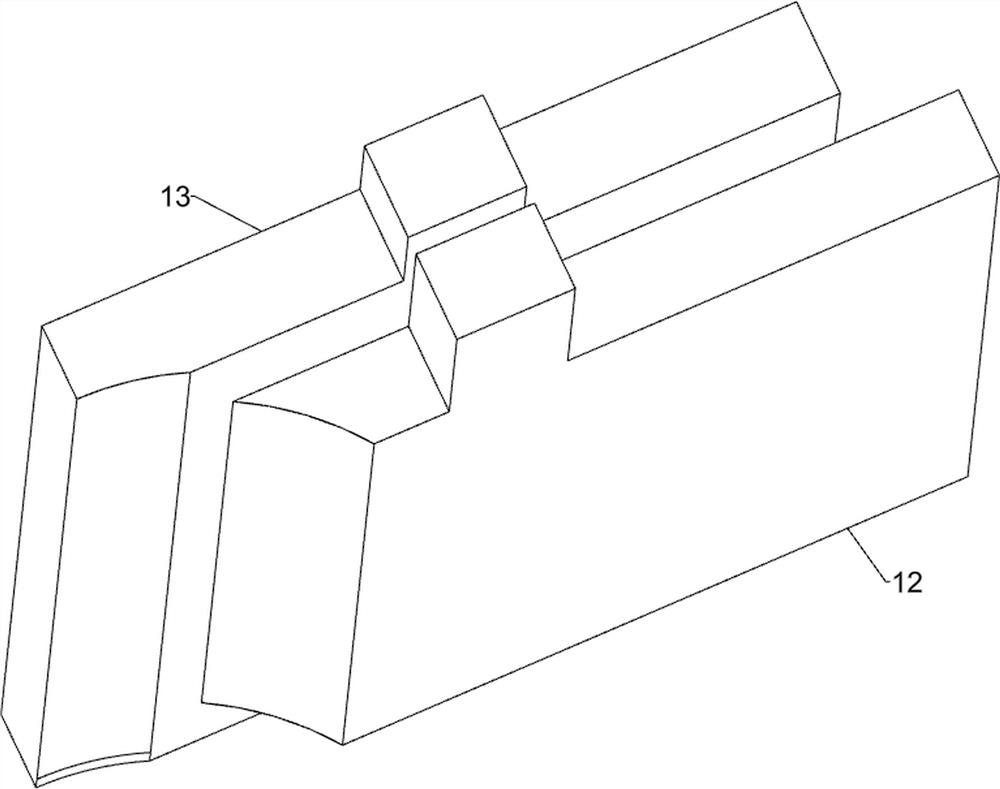

[0035] A kind of diagonally pressing and removing kraft paper cylindrical battery folding device, refer to Figure 1-4 As shown, it includes a support frame 1, a controller 2, a first motor 3, a second motor 4, a pressing mechanism, a rotating mechanism, a placement frame 8, a first storage board 9, a second storage board 10, and a glue spray box 11 , the first limiting plate 12, the second limiting plate 13, the collection box 14, the first electric push rod 15, the connecting plate 16, the second electric push rod 17, the first electric slide rail 18 and the second electric slide rail 19 The support frame 1 is fixedly connected with the controller 2; the support frame 1 is fixedly connected with the first motor 3; the support frame 1 is fixedly connected with the second motor 4; the support frame 1 is provided with a pressing mechanism inside; the second motor 4 It is fixedly connected with the pressing mechanism; a pressing mechanism is connected under the connecting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com