Novel moving contact assembly and contactor

A technology of moving contacts and components, used in relays, electrical components, electromagnetic relays, etc., can solve the problems of easy arc generation, easy damage to components, and inability to protect electrical appliances from lines, and achieves difficult arc and fire, strong overcurrent capability, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

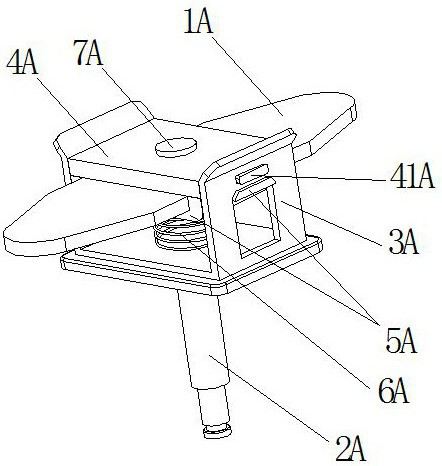

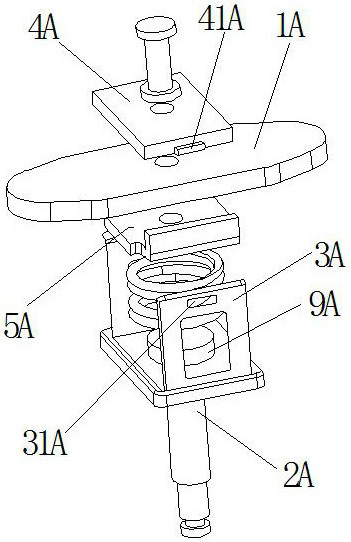

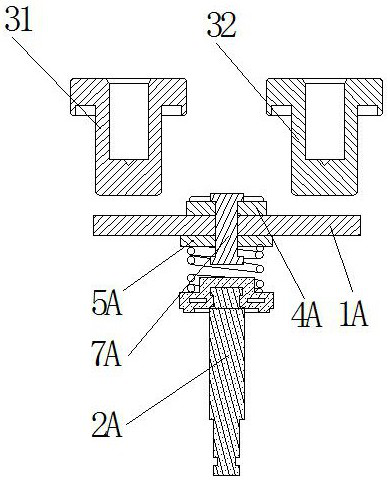

[0020] Such as figure 1 , 2 , 3, 4, and 5 show a new type of moving contact assembly, which includes an electrical connection plate 1A, and the electrical connection plate is connected with a joystick 2A; it is characterized in that: both sides of the joystick are equipped with The upward protruding piece 3A has a side opening 31A, and also includes an upper yoke 4A, a lower yoke 5A and a contact spring 6A, and the two sides of the upper yoke are installed on the side opening. Side protrusion 41A, the side protrusion is installed in the side opening, and the I-shaped column 7A is interspersed in the middle of the upper yoke, that is, the I-shaped column can move on the upper yoke, and the electric There is a hole in the middle of the connecting plate, the middle of the lower yoke has a middle hole in the lower yoke, the I-shaped column passes through the middle hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com