Performance simulation test platform for metal abrasive particle sensor at different depths

A metal abrasive particle and simulation test technology, applied in scientific instruments, particle suspension analysis, measuring devices, etc., can solve problems such as potential safety hazards, poor structural strength, and insufficient safety, and achieve better safety results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

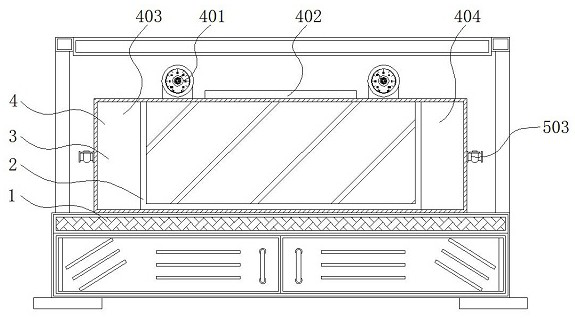

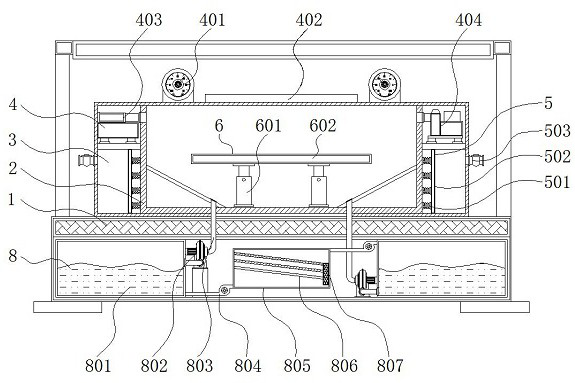

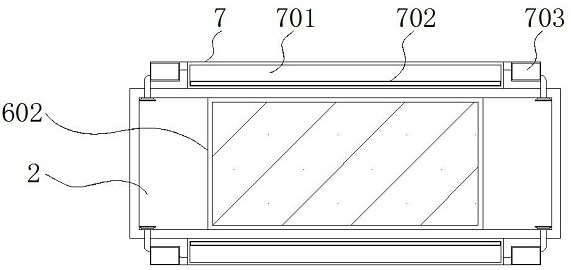

[0028] like Figure 1-5 As shown, the present invention provides a technical solution: a performance simulation test platform for metal abrasive sensors at different depths, including a bearing seat 1, an air pressure adjustment mechanism 4 and a bearing assembly 6, and a simulation frame 2 is fixed above the bearing seat 1, And the outside of the simulation frame 2 is fixed with an outer frame 3, the air pressure adjustment mechanism 4 is arranged on the upper side of the simulation frame 2, and the air pressure adjustment mechanism 4 includes an air pressure gauge 401, a sealing cover 402, an air booster pump 403 and a vacuum pump 404 A barometer 401 is arranged on both sides above the simulation frame 2, and a sealing cover 402 is installed on the upper middle part of the simulation frame 2, and an air booster pump 403 and a vacuum pump 404 are respectively arranged on both sides of the inside of the outer frame 3, and Both the air booster pump 403 and the vacuum pump 404 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com