A vacuum storage container

A vacuum storage and container technology, applied in containers, containers to prevent mechanical damage, packaging under vacuum/special atmosphere, etc., can solve the problems of buffering, shock absorption, poor sealing, and pollution of dairy calcium products, etc. Fixing effect, improving sealing performance, avoiding the effect of sliding back and forth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

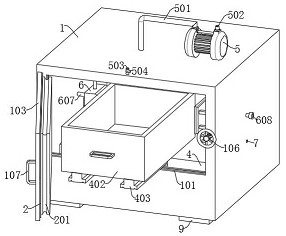

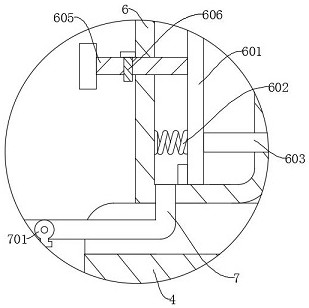

[0030] Embodiment 1: refer to Figure 1-Figure 8 , a vacuum storage container, comprising a container box 1, a storage port 101 is provided on the container box 1, a hinge 102 is fixedly connected to the container box 1, and a container cover 103 is fixedly connected to the end of the hinge 102 away from the container box 1, and Including: rubber airbag 203, arranged around the storage port 101; piston barrel 3, fixedly connected to the inner wall of the bottom of container box 1; buffer block 301, slidably connected to the inner wall of piston barrel 3, and the end of buffer block 301 away from piston barrel 3 is fixedly connected There is a support plate 4; a storage frame 402 is slidably connected to the support plate 4, wherein a spring-302 is connected between the buffer block 301 and the piston cylinder 3; a conduit-303 is connected to the piston cylinder 3 and is far away from the piston cylinder 3 One end of one end communicates with the outer wall of the container box...

Embodiment 2

[0033] Embodiment 2: refer to figure 1 , Figure 7 with Figure 8 , a vacuum storage container, which is basically the same as that of Embodiment 1, furthermore, the locking part includes a screw mandrel 105 and a turntable 106, the screw mandrel 105 is fixedly connected to the container box 1, and the container cover 103 is provided with a mounting hole 104 , the rotating disk 106 is threadedly connected on the screw mandrel 105, and the rotating disk 106 is offset against the container cover 103; , the screw mandrel 105 passes through the mounting hole 104, at this time, the turntable 106 is installed on the screw mandrel 105, and then the turntable 106 is rotated, and the turntable 106 moves to one side of the container box 1, pushing the sealing strip 2 inside the container cover 103 and the container box 1, the outer sides are closely attached to each other, thereby improving the sealing performance of the joint between the container cover 103 and the container box 1. ...

Embodiment 3

[0034] Embodiment 3: refer to figure 1 , Figure 5 with Figure 7 , a vacuum storage container, which is basically the same as that of Embodiment 1, furthermore, the negative pressure component includes an air pump 5, the air pump 5 is fixedly connected to the container box 1, and the input end of the air pump 5 passes through the inner wall of the container box 1 Pipeline one 501 is connected, and the output end of air suction pump 5 is connected with pipeline two 502; Start air suction pump 5, and air suction pump 5 can extract the air in container box 1 through pipeline one 501, then discharge by pipeline two 502, make The container box 1 is in a hollow state, so as to prevent the milk calcium products from being polluted by oxidized molecules in the air in the container box 1 when the milk calcium products are stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com