Rigid hinge device of folding product

A rigid hinge and product technology, applied in the direction of pivot connection, can solve the problems of large lateral swing, poor connection rigidity, and large sway, and achieve the effect of simple structure of rigid hinge, low material consumption and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

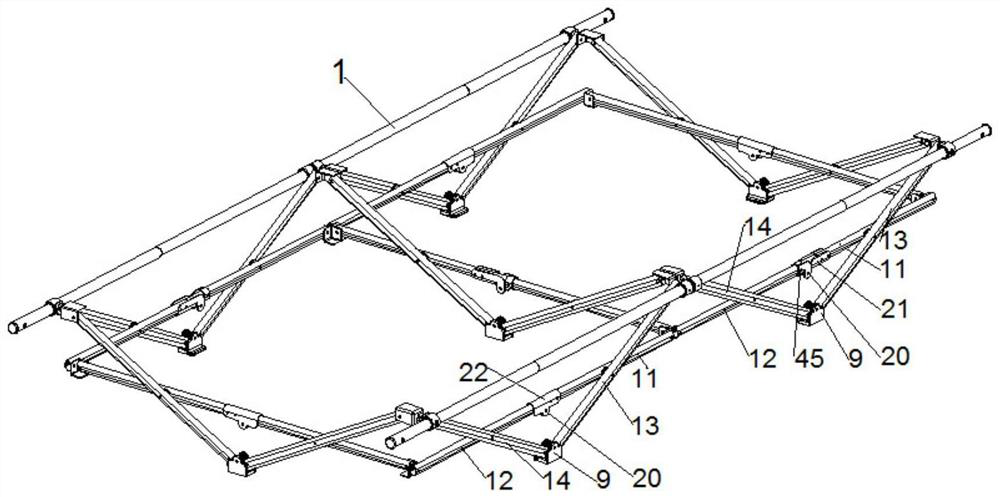

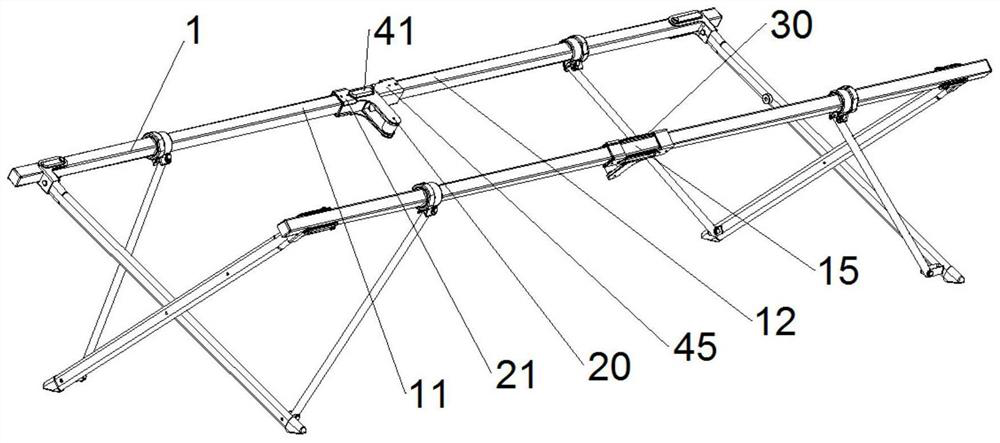

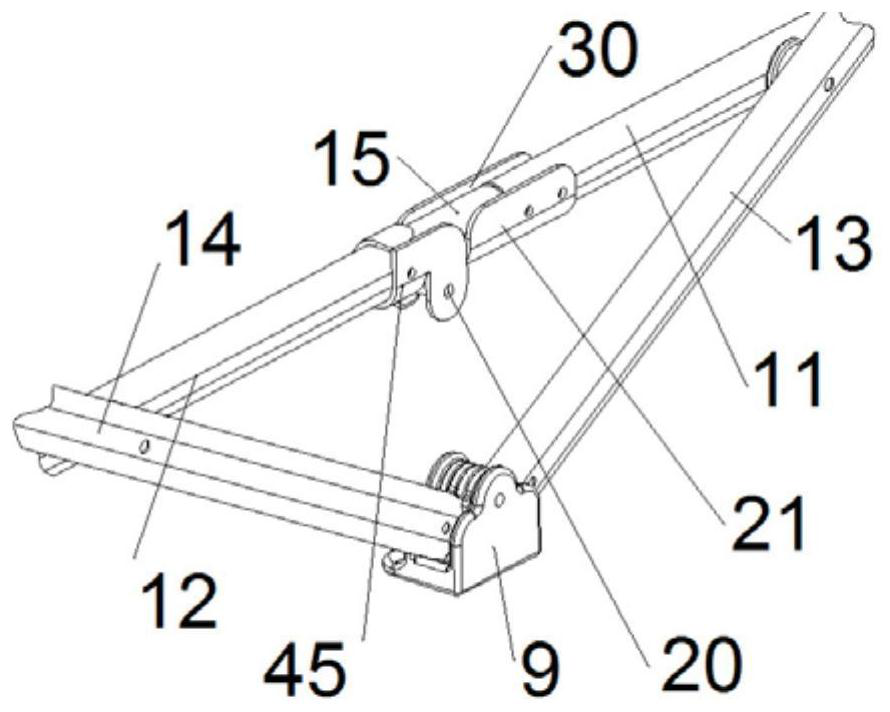

[0104] refer to Figure 1 to Figure 49 , folding product rigid hinge device, in the involved folding bed (1), folding chair (2), folding cart (3), folding pergola (4), folding table, folding hammock, folding storage cabinet, folding door, folding truss In other folding products or folding components, it includes: same-plane horizontal rigid hinge tube A (11), same-plane horizontal rigid hinge tube B (12), same-plane rigid hinge device (21, 22, 23), and also includes: same-plane Oblique intersection tube A (13), obliquely intersecting tube B on the same plane (14), oblique rigid hinged tube A on the same plane (17), oblique rigid hinged tube B on the same plane (18), and hinged joints on the same plane (45), wherein, The same plane horizontal rigid hinge tube A (11) and the same plane horizontal rigid hinge tube B (12) are hinged in the same plane, similarly, the same plane oblique rigid hinge tube A (17) and the same plane oblique rigid hinge tube B (18) Also hinged in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com