Capacitor pin bending and cutting device

A technology for cutting capacitors and feet, which is applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as low safety, and achieve the effect of improving low safety and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

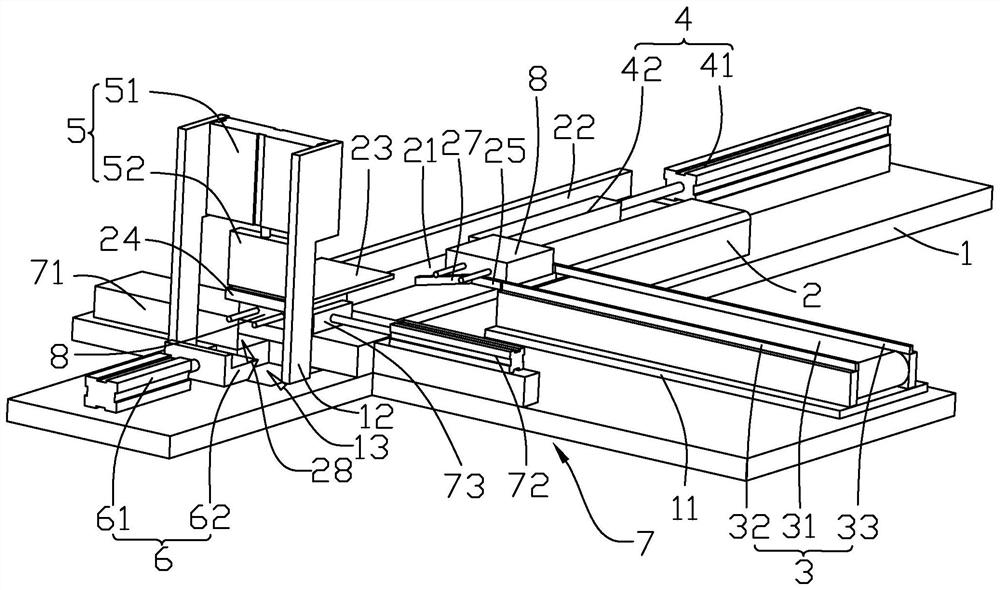

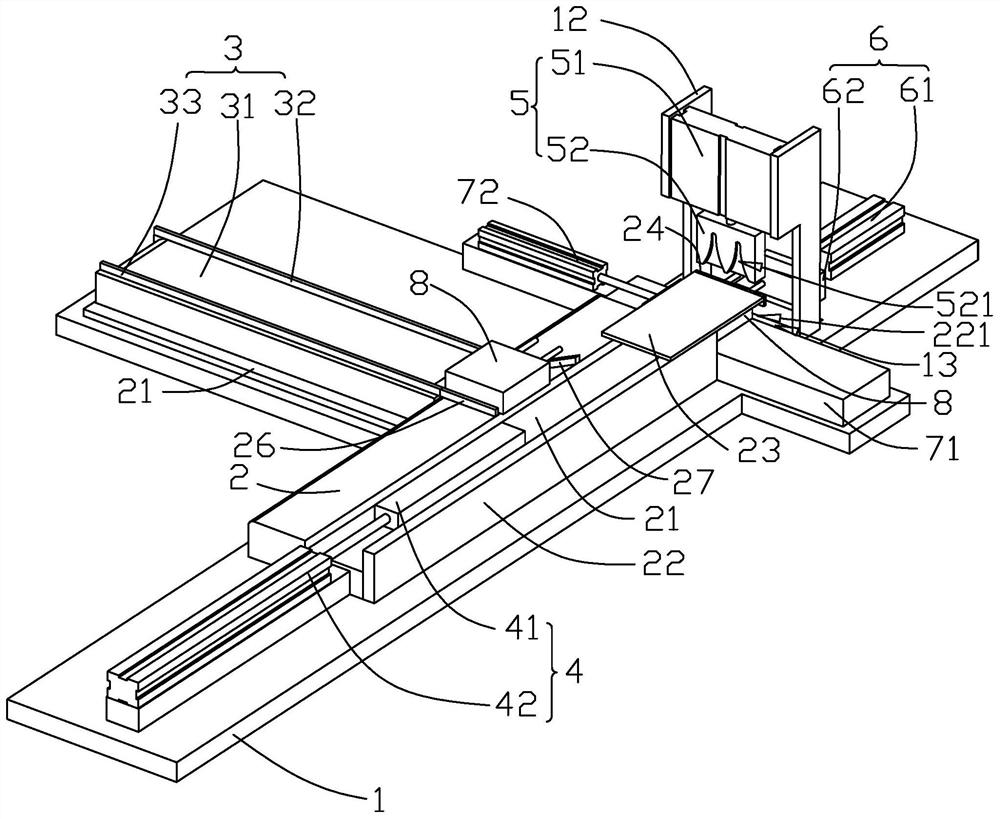

[0035] Contraction below Figure 1-2 Further detailed description of the present application.

[0036] A capacitor disclosed embodiments Cutting bending apparatus of the present application. Refer figure 1 with figure 2 , Curved legs cutting apparatus comprises a table 1, feed table 2, the conveying mechanism 3, pusher means 4, 5 the folding mechanism, the cutting mechanism 6 and the takeup device 7, feed table 2 is fixedly connected to the top surface of the table 1, cuboid feed table 2, table 2 material guiding groove defines a top surface 21, a rectangular parallelepiped guide chute 21, feed channel 21 communicates with both ends of the feed table 2, the guide chute 21 and the side surface side of the feed table 2 communication, feed table 2 and the guide chute 21 side communicating with the side plate 22 is fixedly connected with the guide chute 21 is provided with a capacitor 8, 8 sliding on the capacitor bottom chutes 21; the transport mechanism 3, pusher means 4, 5 the foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com