A prevention and control device and method for avoiding wrong oil unloading

A technology for prevention and control of areas, applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., which can solve the problems of small sampling volume and data easily affected by the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

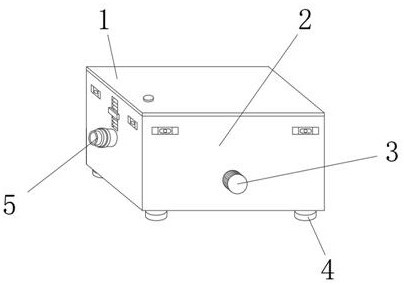

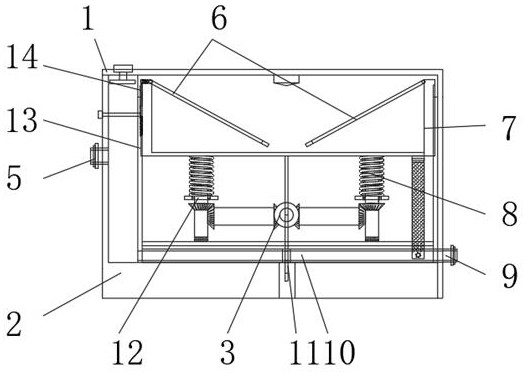

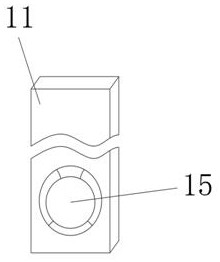

[0040] like Figure 1-3 As shown in the figure, a prevention and control device for avoiding wrong oil unloading includes a prevention and control device main body 2, and a liquid inlet 5 and a liquid outlet 9 are opened on both sides of the prevention and control device main body 2, and is characterized in that: the prevention and control device main body 2 A sealing cover 1 is rotatably connected to the upper end surface of the control device body 2, and a partition plate 13 is arranged inside the main body 2 of the prevention and control device. An infusion tube 10 is provided, one end of the infusion tube 10 is communicated with the liquid outlet 9, a first spring 8 is arranged in the control area, and the other end of the first spring 8 is elastically connected with a constant volume bin 7 for oil measurement. The capacity bin 7 is elastically connected inside the control area through the first spring 8, and the lower end face of the constant capacity bin 7 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com