Laser recognition device and method for welding

A laser identification and welding device technology, which is applied to welding accessories, devices for providing/removing protective gas, etc., can solve the problems of short service life of shielding parts, large energy consumption of protective gas, and influence on sensor measurement accuracy, etc., to reduce heat Loss, improve heat dissipation efficiency, improve the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

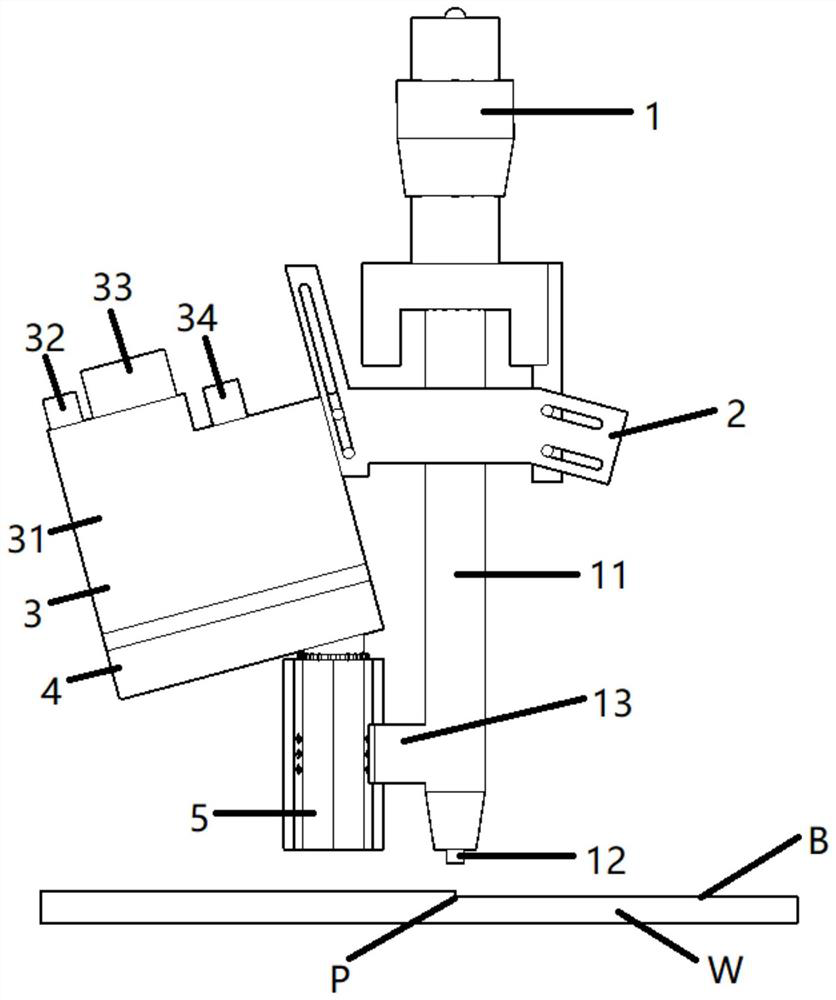

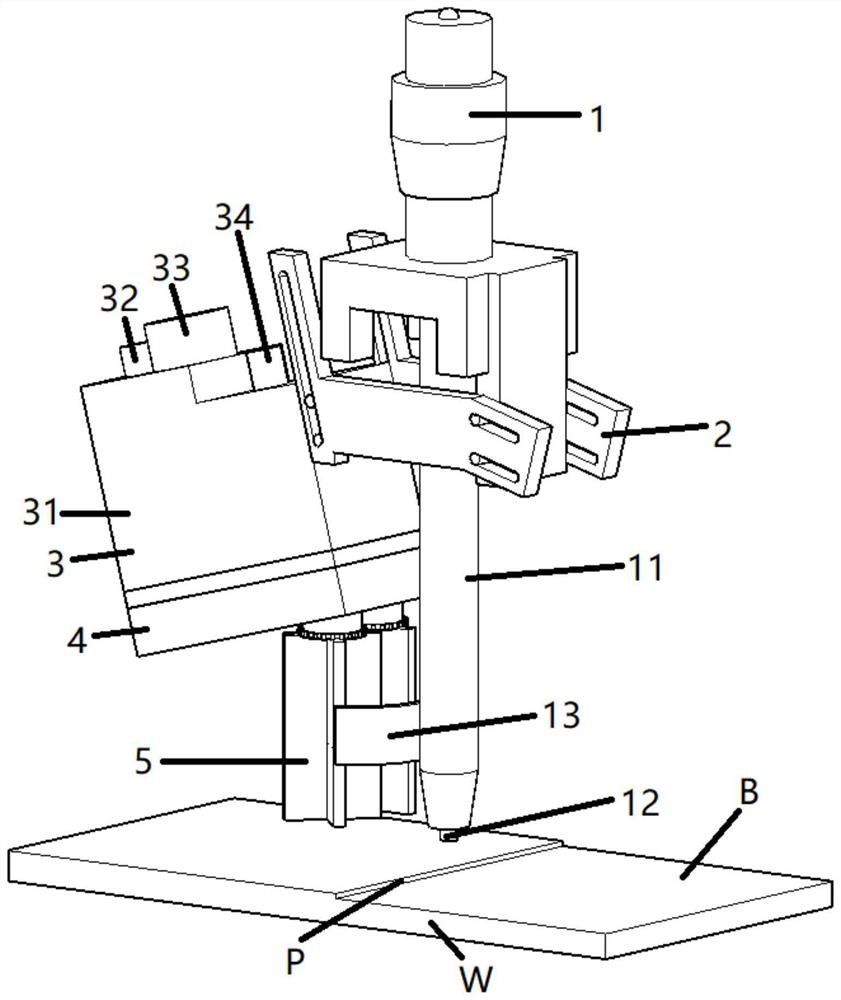

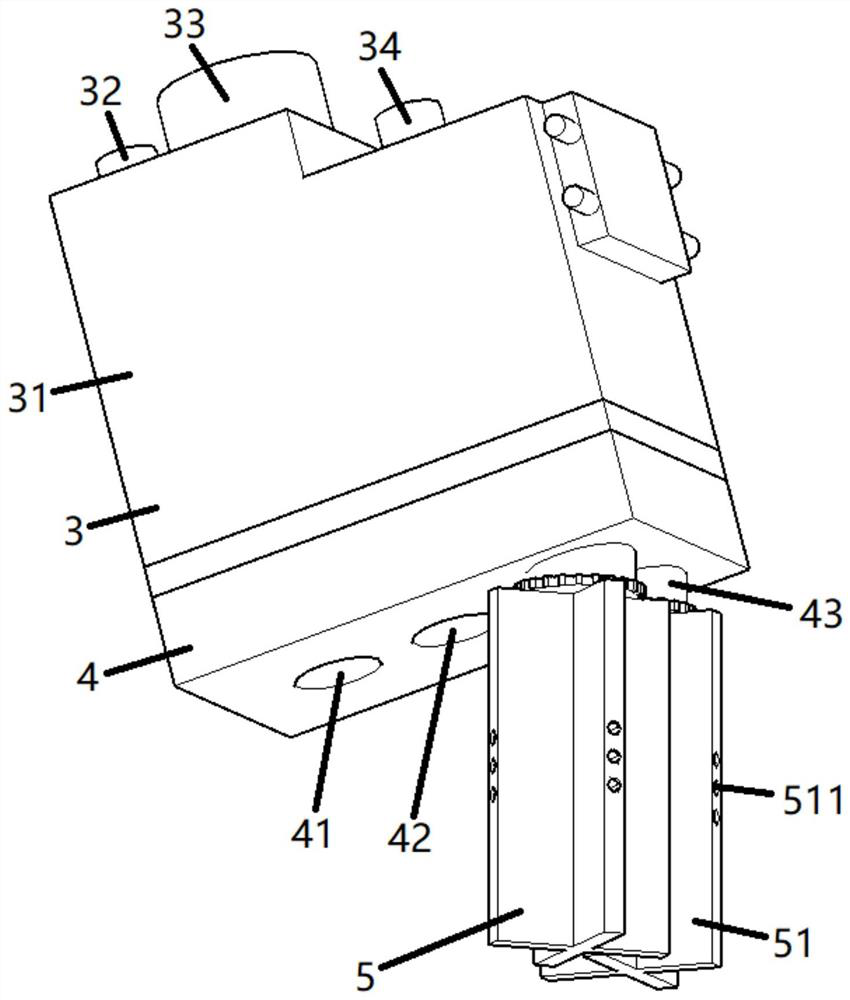

[0032] Such as figure 1 As shown, a laser identification device for welding includes: a welding device 1, a fixture 2 for installation, a sensor unit 3, a protective cover 4, and a shielding part 5;

[0033] Such as figure 1 As shown, the sensor unit 3 according to this embodiment is mounted on the welding device 1 through the jig 2; the welding wire 12 is supplied to the welding torch 11 of the welding device 1; A voltage is ap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap