Injector unit for the injection of fuel, and method for the operation of an injector unit of this type

A technology of injectors and fuels, applied in the direction of fuel injection devices, charging systems, engine components, etc., which can solve problems such as premature replacement, increased fuel consumption, and wear of armature stoppers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

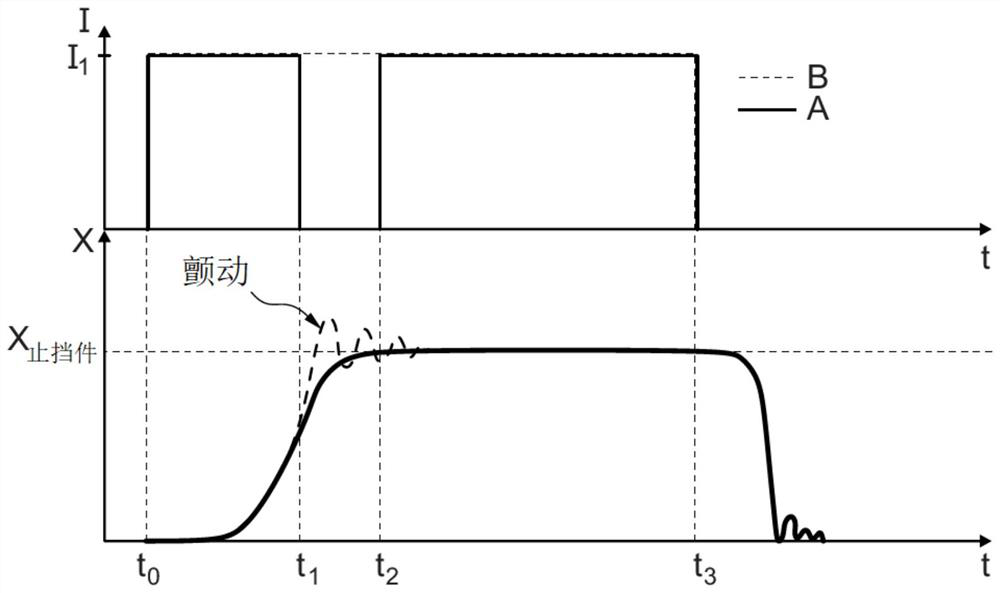

[0041] figure 1 Shows two diagrams superimposed over time t, wherein the upper one of the two diagrams shows the actuation signal I or the electromagnetic signal guided to the electromagnetic signal according to the invention (solid line A) and according to the prior art (dotted line B). The direction of the current in the iron. The graph located below shows the displacement (x) of the armature element as a function of various actuation signals, where the dotted line represents the control behavior according to the prior art and the solid line represents the control according to the invention.

[0042] From the graph, it can be seen that at time t 0 The armature element is placed on the seat plate such that the through hole is sealed.

[0043] now at time t 0 Set the current signal I used to control the electromagnet to the value I 1 , which is non-zero and therefore causes the armature element to move from the seat plate towards the lift-limiting stop, the armature elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com