On-site water diversion, treatment and reinjection device and method

A technology of processor and fine processor, which is applied in the field of reinjection device, treatment, and local water division, which can solve the problems of unsatisfactory original process, high construction cost, and substandard sewage water quality, and achieve low energy consumption and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

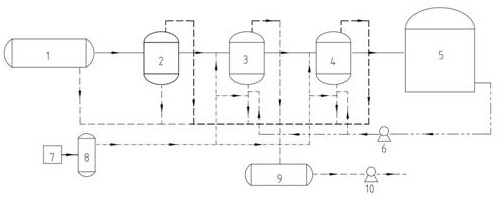

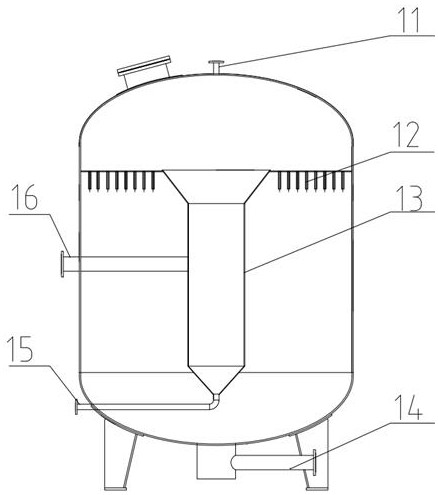

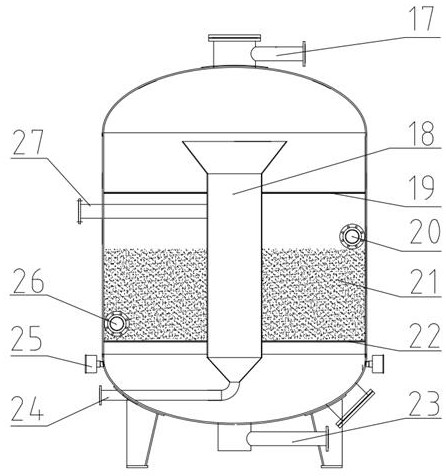

[0030] Such as Figure 1-5 Shown, 1, a kind of in-situ water separation, treatment, reinjection device, comprises three-phase separator 1, sludge water separator 2, coarse processor 3, fine processor 4, water injection tank 5, air compressor 7, Gas storage tank 8, buried sewage tank 9, the water inlet of the sludge water separator 1 is connected to the water outlet of the three-phase separator 2; the water inlet of the rough processor 3 is connected to the sludge water separator 2 The outlet pipe mouth of described fine processor 4 is connected with the outlet pipe mouth of coarse processor 3; The outlet pipe mouth of fine processor 4 is connected with the water inlet pipe mouth of water injection tank 5, and described air pressure The outlet of machine 7 is connected with the inlet of gas storage tank 8, and the outlet of gas storage tank 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com