A multi-mode adaptive mechanical gripper

An adaptive, multi-mode technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve problems such as management, operation and maintenance inconvenience, product scrap rate increase, object surface damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

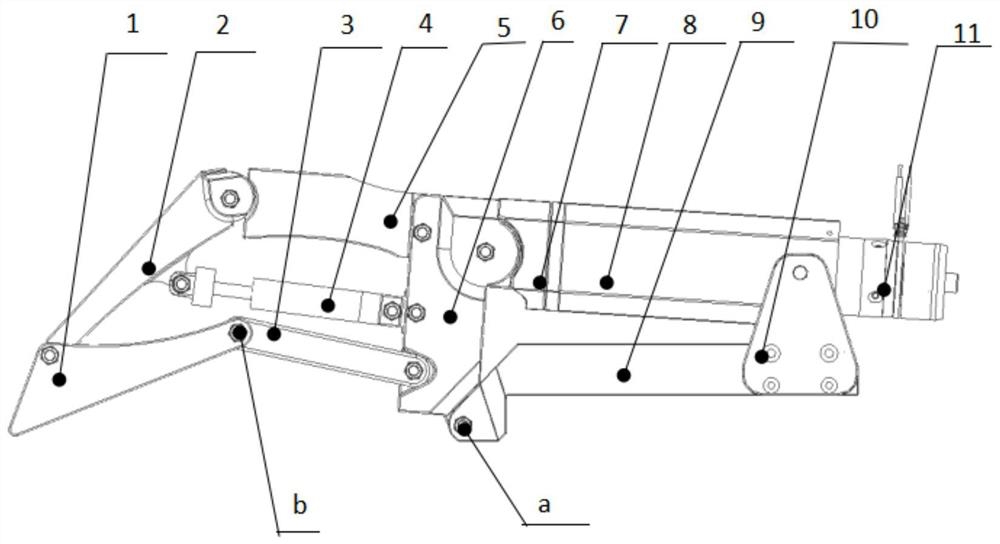

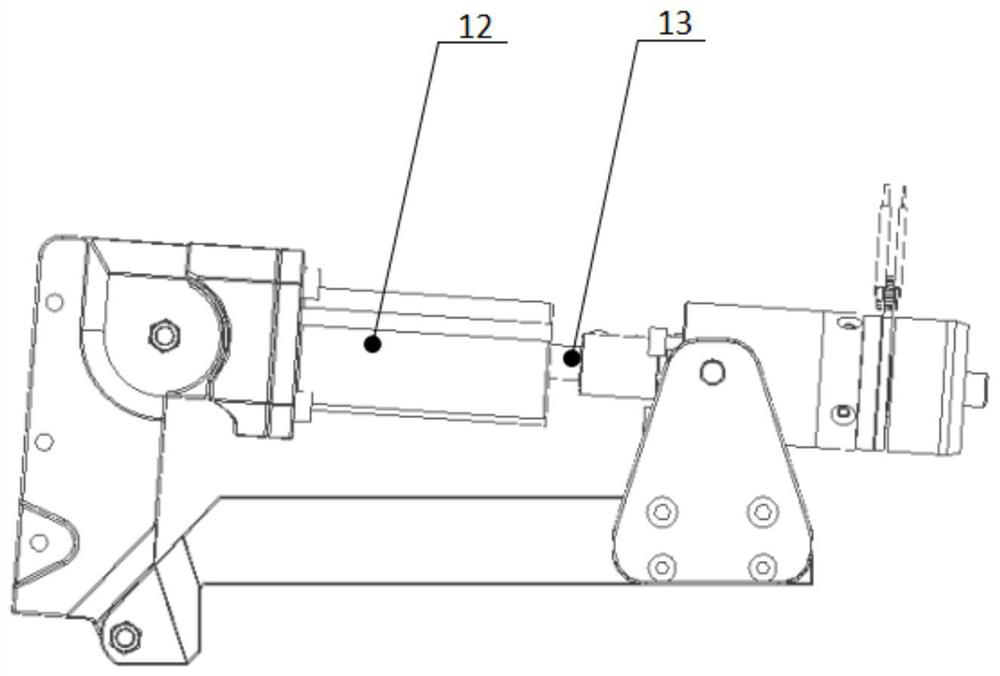

[0021] like figure 1 As shown, a multi-mode adaptive manipulator includes a finger 31 , a finger driving module 33 , and a central driving module 32 . The fingers 31 and the finger driving module 33 are installed on the casing of the central driving module 32 . The finger driving module 33 is connected with the driving module through the chute structure. The finger 31 and the finger driving module 33 form a link mechanism, and the finger 31 is connected to the finger driving module through two hinges.

[0022] The finger 31 is composed of a soft body knuckle 1, a finger lever 2, a finger link 3, a spring strut 4, and an end knuckle 5. The soft knuckle 1 and the finger lever 2, the soft knuckle 1 and the finger link 3, the finger link 3 and the rocker 6, the spring strut 4 and the finger lever 2, and the spring strut 4 and the rocker 6 are hinged. The degree of freedom of the finger is 2, which is an underactuated flexible finger, which can achieve flexible grasping according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com