Tactile feedback device

A tactile feedback and touch layer technology, applied in the field of tactile feedback, can solve problems such as slow response time, and achieve fast response, simple operation, and rich and realistic feedback methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

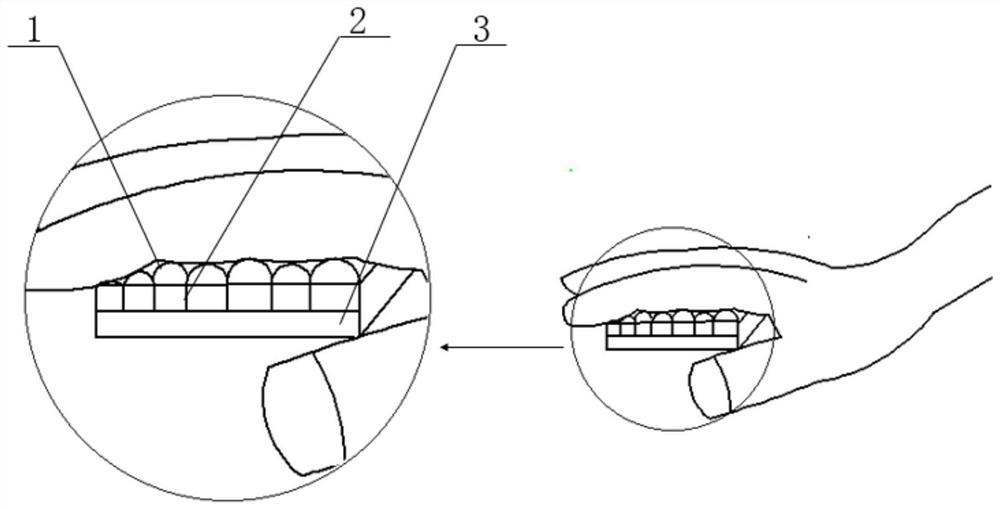

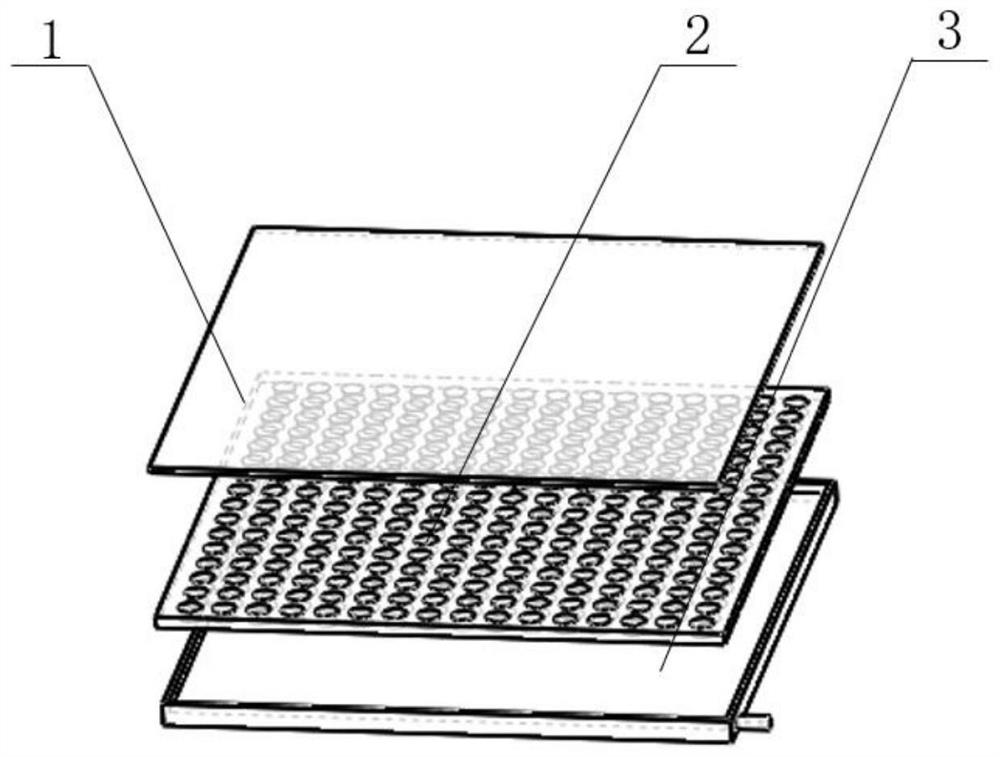

[0028] A tactile feedback device disclosed in the present invention, such as Figure 1 to Figure 3 As shown, it consists of a tactile feedback unit, an electric field control unit and a pressure generating unit. The tactile feedback unit is as follows figure 2 As shown, it consists of a touch layer 1 , a tactile feedback differentiation unit 2 and a liquid cavity 3 . The electric field control unit is composed of symmetrical electrodes placed on the side of the honeycomb through hole in the tactile feedback differential unit and a corresponding control circuit. The pressure generating unit is any device that can provide pressure. The touch layer 1 is located on the uppermost layer, the tactile feedback differential unit 2 is located on the lower layer of the touch layer 1, and is sealed and bonded to the touch layer, and the liquid chamber 3 is located on the lower layer of the tactile feedback differential unit 2, and is connected to the data volume feedback differential un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com