Integrated clean room air purification system and control method

An air purification system and purification system technology, which is applied in air conditioning systems, heating methods, space heating and ventilation, etc., to achieve low wind resistance, reduce energy consumption, and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

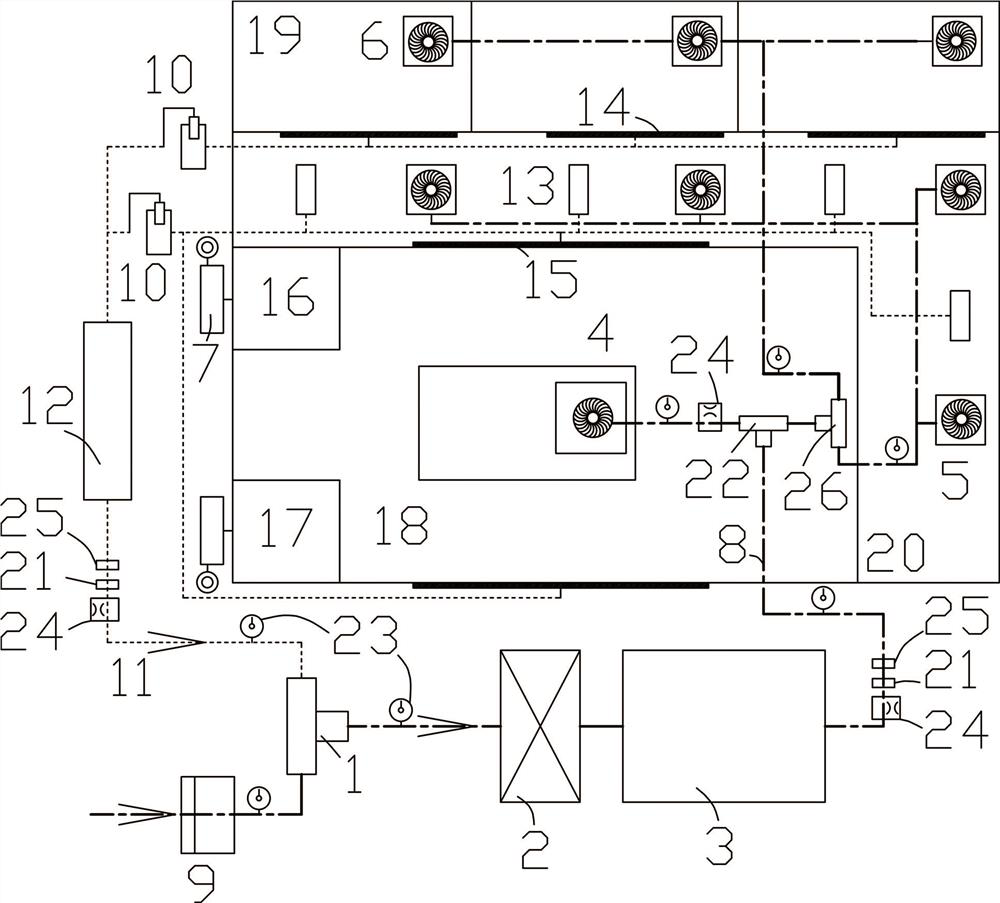

[0049] like figure 1 , an integrated clean room air purification system, which includes a fresh air unit 9, an air inlet distribution valve 1, an air purification system 2 and a circulation unit 3;

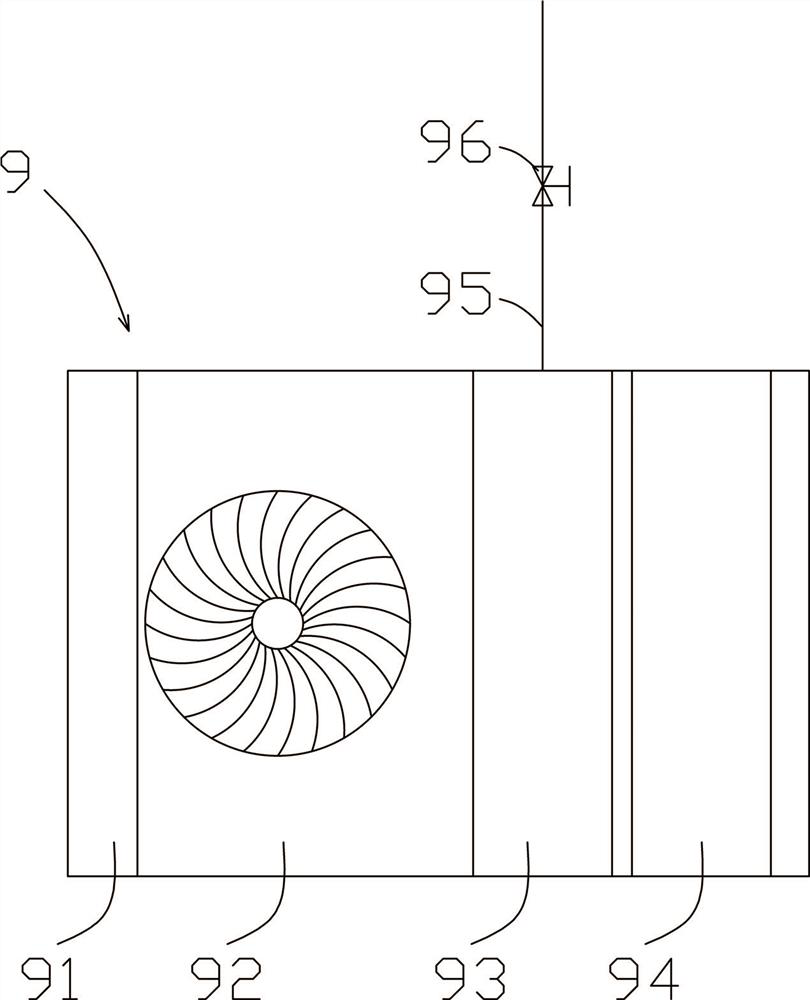

[0050] The structure of the fresh air unit 9 is as follows figure 2 As shown in the figure, a filter device 91 is provided at the inlet position, and the intake air is pretreated first. The filter device 91 preferably adopts an F6 medium-efficiency filter or other filter with lower wind resistance according to the air quality. The fresh air unit 9 is also provided with a fresh air fan 92, a temperature regulator 93 and a humidity regulator 94. The temperature regulator 93 preferably adopts an air energy temperature regulator, and is supplemented by an auxiliary heating system, such as electric auxiliary heating, or an additional heating water pipe 95. Steam heating pipes, etc., an opening adjustment valve 96 is provided on the heating water pipe 95 or the steam heating pipe, and...

Embodiment 2

[0077] A control method using the above-mentioned integrated clean room air purification system, comprising the following steps:

[0078] S1. Humidity priority control is adopted. Under summer conditions, the fresh air is cooled and dehumidified by the fresh air unit 9 and then mixed with the return air from the return air pipeline 11, and is cooled or heated to the design air supply temperature in the circulation unit 3 for a second time. back air;

[0079] Under winter conditions, when the outdoor fresh air is lower than 5°C, the fresh air is preheated to 5°C by the fresh air unit 9, heated to the set temperature value by the heat coil in the fresh air unit, and sent to the circulation unit 3 and the return air. After mixing, it is heated by the hot water coil in the circulating unit for a second time, and then humidified by the humidifier until the temperature and humidity meet the setting and then supply air;

[0080] S2. Compare the pressure and air flow rate of the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com