Automatic crushing device for raw material processing

A crushing device and raw material technology, applied in grain processing, etc., can solve problems such as narrow application range, inconvenient use, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

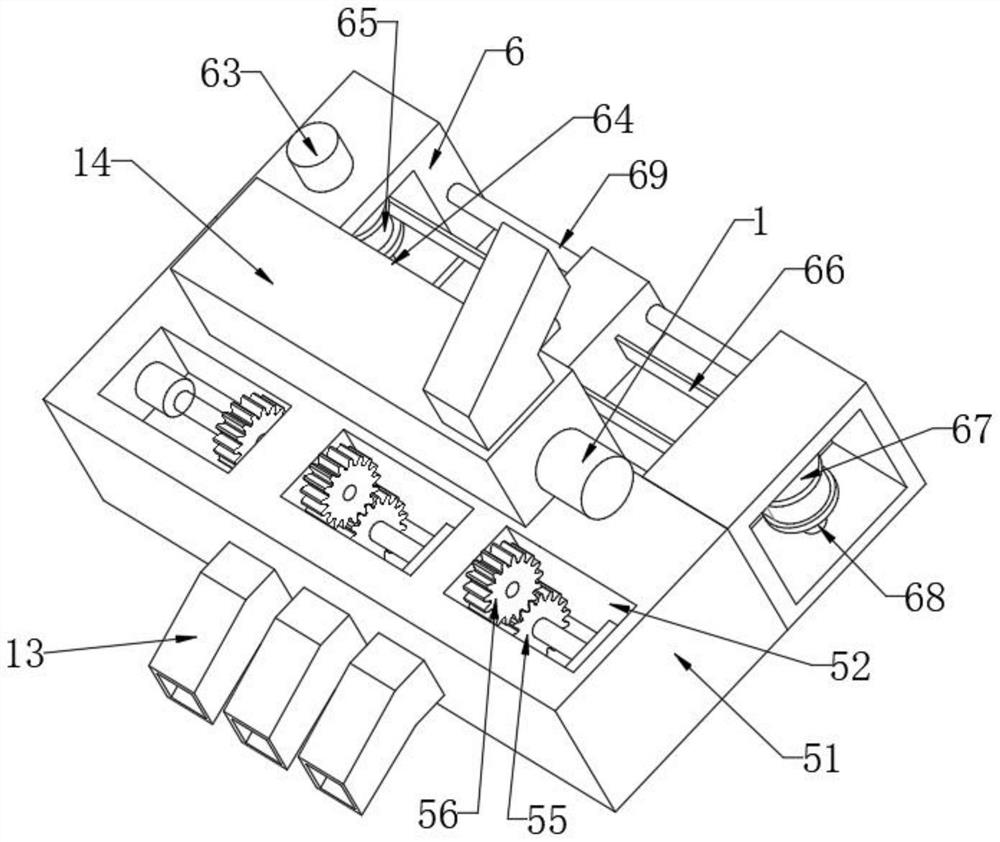

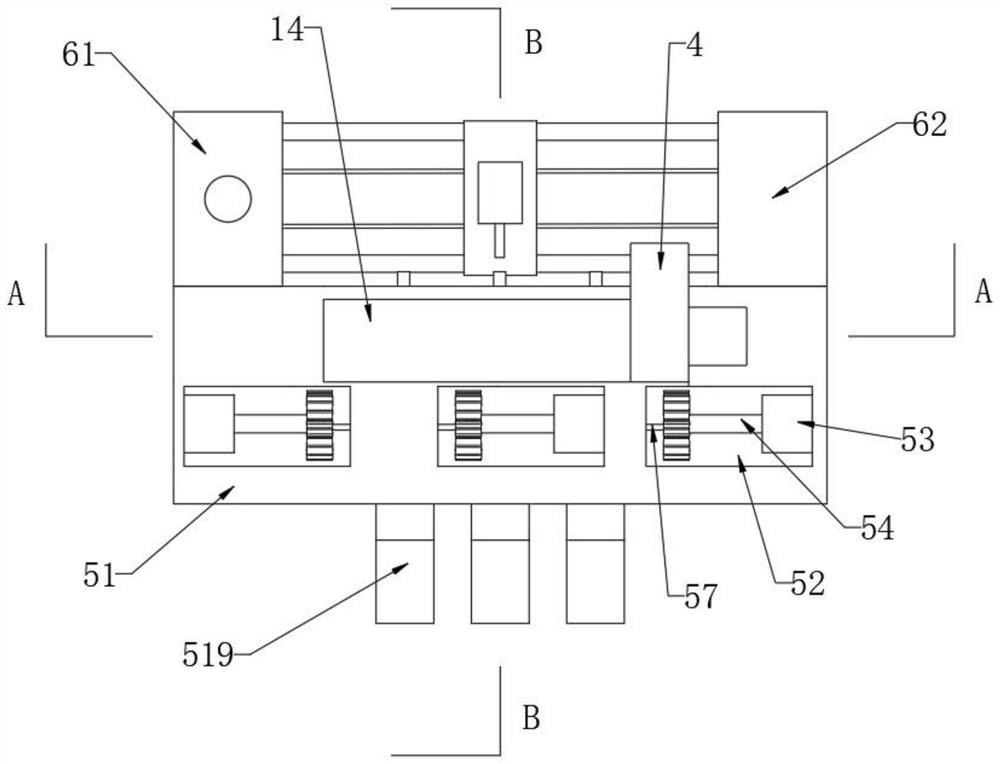

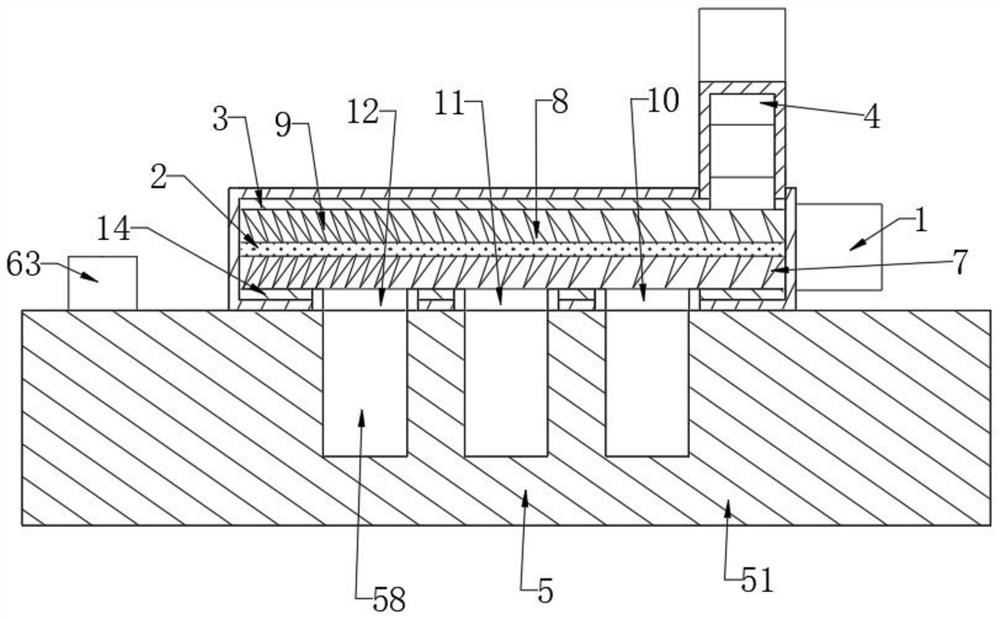

[0034] see Figure 1-6 , an automatic crushing device for raw material processing, composed of a support plate 14, a discharge mechanism 5, and an auxiliary mechanism 6, can process raw materials into particles of different sizes according to needs, is easy to use, has a wide application range, and improves processing efficiency.

[0035]Wherein, the inner wall of the support plate 14 is fixedly connected with the fixed cylinder 3, the side wall of the support plate 14 is fixedly connected with the first motor 1, and the outlet end of the first motor 1 is fixedly connected with the first rotating rod 2 through a coupling. , the first rotating rod 2 runs through the supporting plate 14, and the supporting plate 14 and the first rotating rod 2 are rotatably connected together by bearings, the outer wall of the first rotating rod 2 is provided with a first-stage blade 7, and the first-stage blade 7 arrays are arranged on the outer wall of the first rotating rod 2, the first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com