Eddy current damper with axial double-reed structure

An eddy current damper and double-reed technology, applied in springs/shock absorbers, springs, magnetic springs, etc., can solve the problem of failure to work properly, to analyze and accurately predict the real disturbance source of micro-vibration, and to affect the imaging quality of optically sensitive loads. and other problems, to achieve the effect of ensuring the effective working range, small axial rigidity and large radial rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

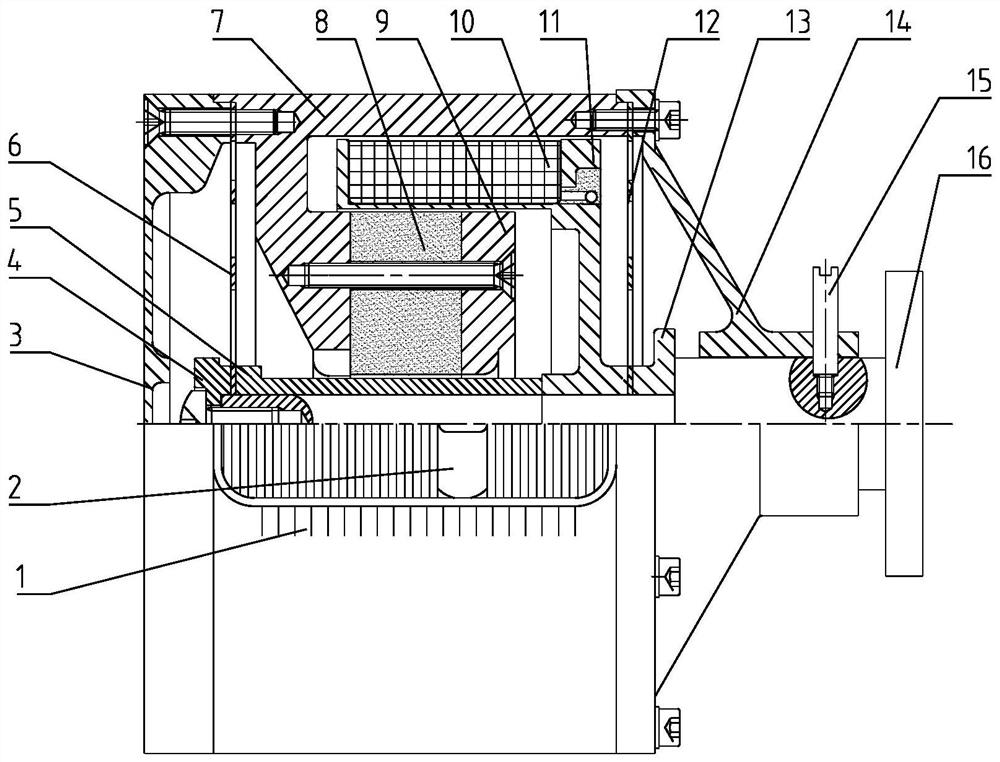

[0021] like figure 1 An axial dual spring structures illustrated eddy current damper, comprising a permanent magnet 8; 8 a permanent magnet fixedly mounted in the housing 7, the coil 10 surrounds the permanent magnet 8 is mounted and fixed to the bracket 11 relative to the shaft and the housing 7 to form a primary eddy current exercise, and the damping coefficient adjusting means 7 on the casing 2, the damping coefficient adjusting means 2 electrically connected in series with the coil 10.

Embodiment 2

[0023] Based on Example 1, and the corresponding damping means has a damping coefficient adjusting the position of the scale 1 on the upper case 2 7.

Embodiment 3

[0025] Based on Example 1, and the bracket 11 by the first spring 12 and second spring 6 is fixed to the housing 7, the housing 11 and the bracket 7 relative axial movement of the eddy current configuration views.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com