Stacking and discharging mechanism for storage and using method

A palletizing and warehousing technology, applied in the field of palletizing and unloading mechanism for warehousing, can solve problems such as product falling and product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

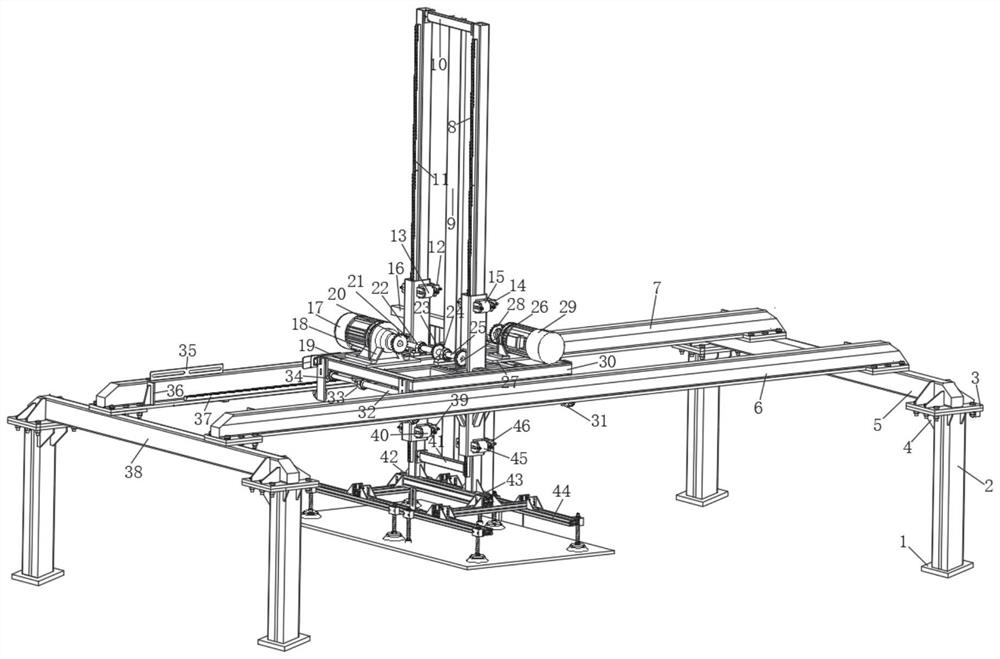

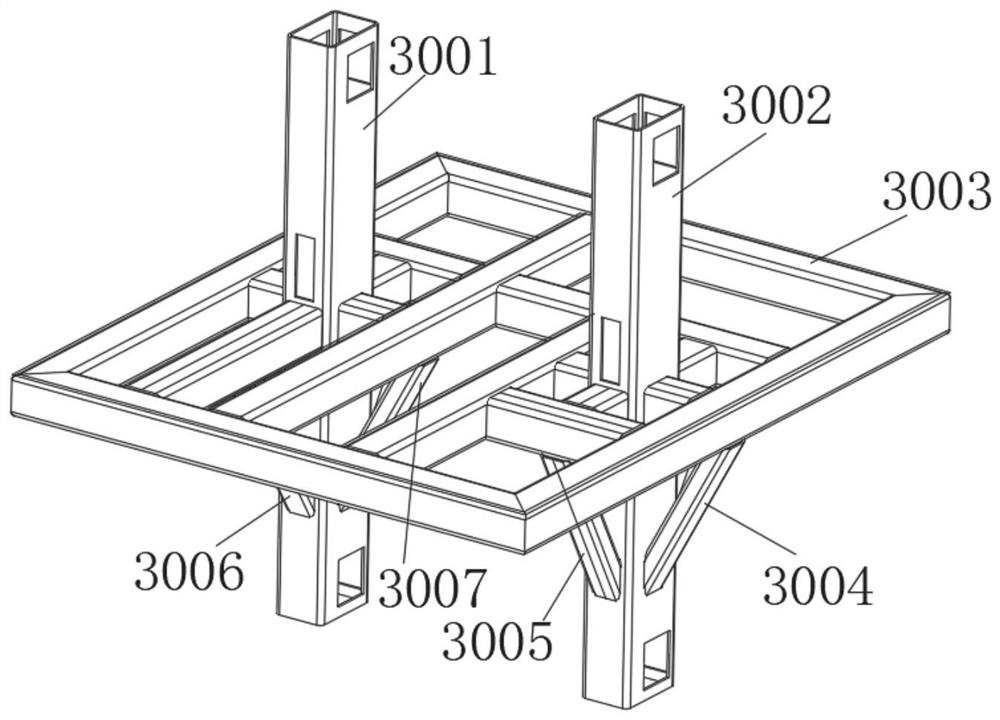

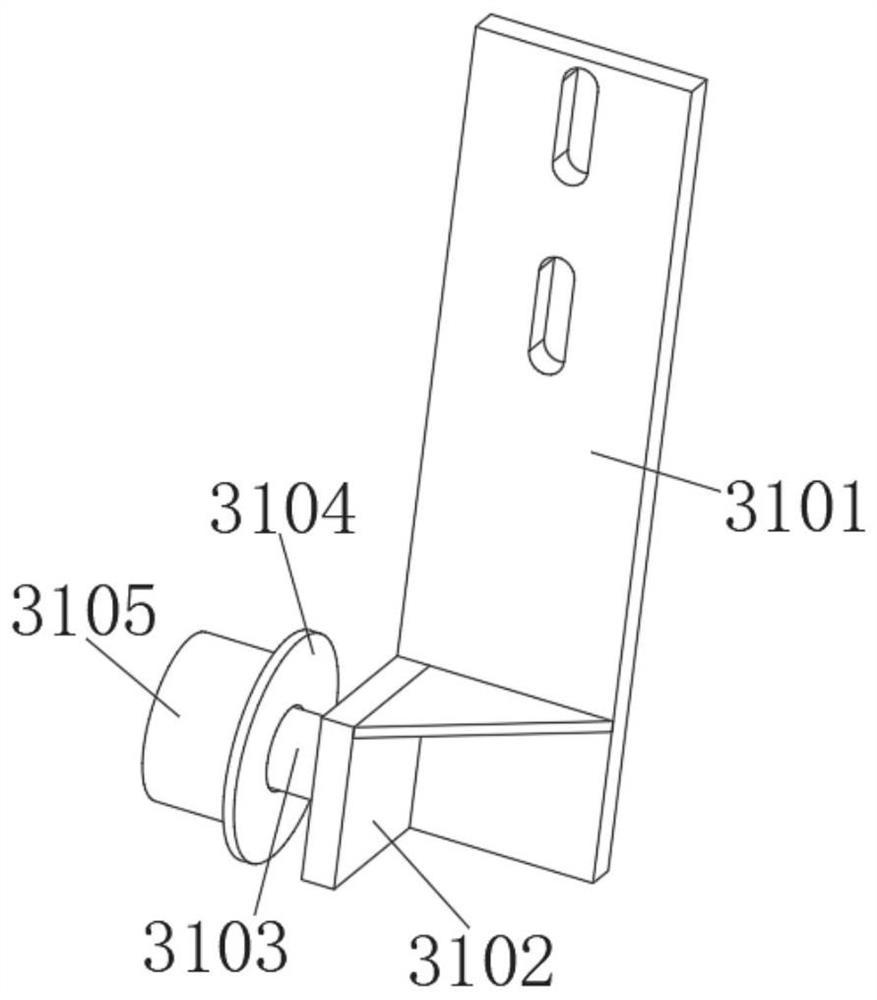

[0038] Such as Figure 1-9As shown, the stacking and unloading mechanism for storage includes a pad 1, a support leg 2, a connecting plate 3, a triangular support plate 4, a first vertical beam 5, a first cross beam 7, a first vertical rack 8, and a central column 9 , the second vertical rack 11 and the first side wheel 13, the upper end of the cushion block 1 is provided with a support leg 2, the upper end of the support leg 2 is provided with a connecting plate 3, and one end of the connecting plate 3 is provided with a triangular support plate 4, the triangular support plate 4 The upper end of the support plate 4 is provided with a first vertical beam 5, the upper end of the first vertical beam 5 is provided with a second beam 6, one end of the second beam 6 is provided with a first beam 7, and the upper end of the first beam 7 is provided with a first beam. Vertical rack 8, one end of the first vertical rack 8 is provided with a central column 9, one end of the central col...

Embodiment 2

[0048] The method of using the palletizing and unloading mechanism for storage, the steps of the method are as follows:

[0049] Step 1: first connect the palletizing and unloading mechanism for storage with an external power supply, and then drive the rotation of the first driving motor 17 and the second driving motor 29 at one end of the palletizing and unloading mechanism for storage through the external power supply. The rotation of the first driving motor 17 and the second driving motor 29 provides strong power support for the product palletizing work of the palletizing and unloading mechanism for the warehouse;

[0050] Step 2: The rotation of the first driving motor 17 further drives the rotation of the first gear 20 at one end, while the first gear 20 rotates, it further drives the rotation of the second gear 21 at one end, and the rotation of the second gear 21 drives the rotation of the second gear 21 at one end. The rotation of a driving rod 25, the first driving ro...

Embodiment 3

[0054]Working principle: firstly, connect the palletizing and unloading mechanism for storage with an external power supply, and then drive the rotation of the first drive motor 17 and the second drive motor 29 at one end of the palletizing and unloading mechanism for storage through the external power supply. The rotation of a driving motor 17 further drives the rotation of the first gear 20 at one end, and the first gear 20 further drives the rotation of the second gear 21 at one end while rotating, and the rotation of the second gear 21 then drives the rotation of the first drive rod 25 at one end. Rotate, and then drive the rotation of the third gear 23 and the fourth gear 26 at one end while the first drive rod 25 rotates, and then drive the second vertical rack 11 at one end to move up and down through the rotation of the second gear 21, and move up and down through the fourth gear 26 The rotation further drives the first vertical rack 8 at one end to move up and down. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com