Separating device for overlapped shears

A separation and re-shearing technology, which is applied in the direction of transportation and packaging, manipulators, chucks, etc., can solve the problems of unstable adsorption quantity of mechanical suction cups, failure of the next process, and easy overlapping of scissor blades, etc., so as to reduce the difficulty of maintenance and repair , Improve the production safety factor and reduce the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

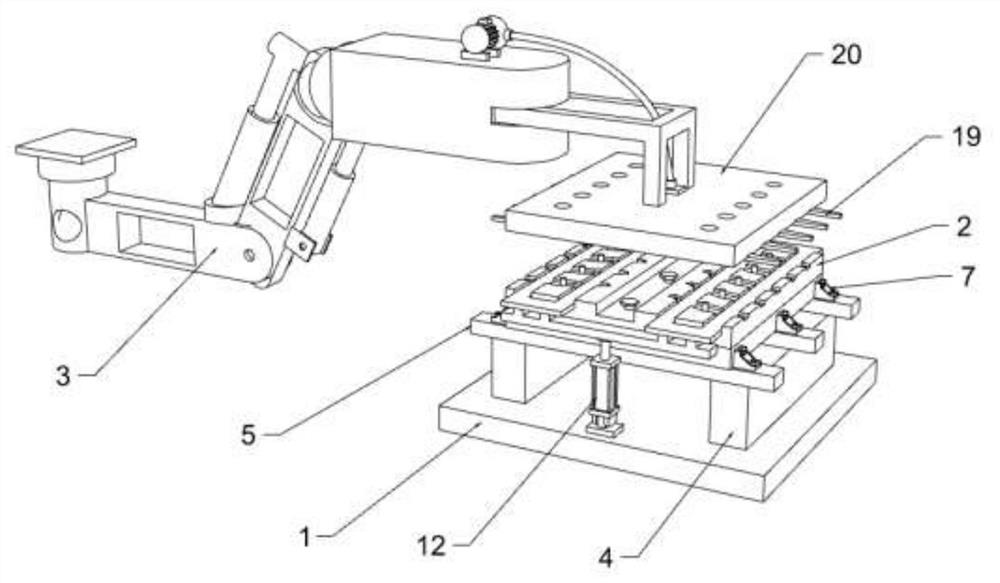

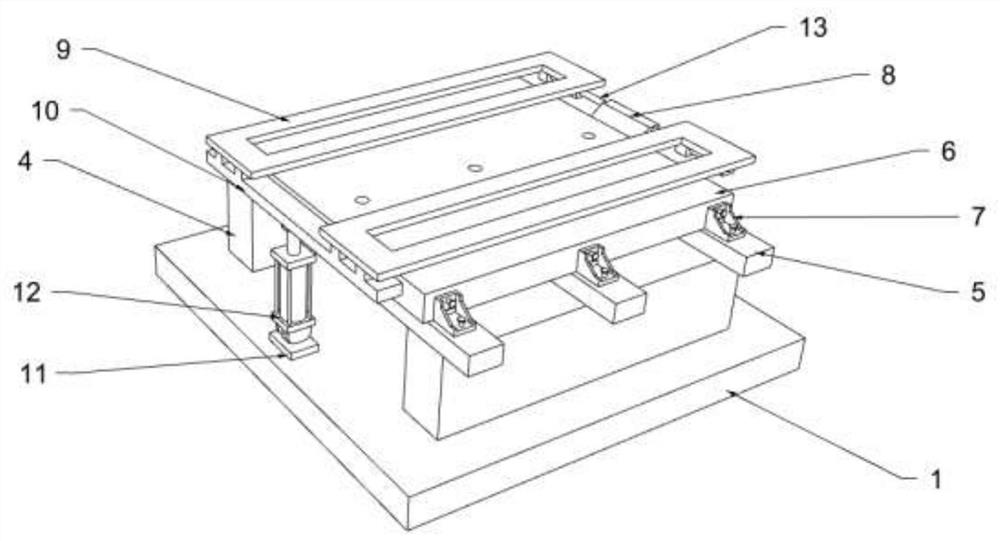

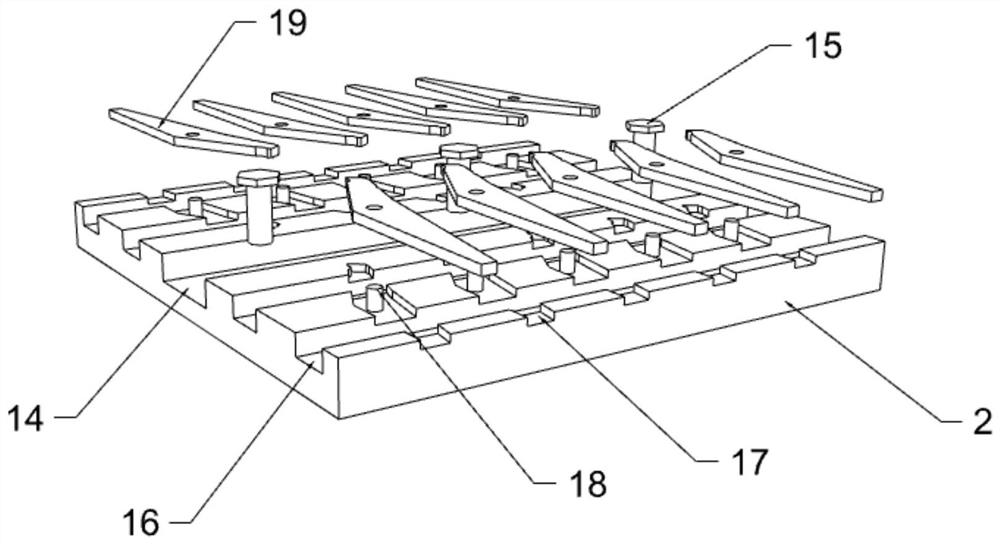

[0028] Embodiment: when this re-shearing separation device is in use, firstly control the mechanical arm 3, then control the suction disc 20 to absorb the scissors 19, then the mechanical arm 3 controls the suction disc 20 to align with the suction disc 2, and the magnetic attraction force of the suction disc 2 will be The excess scissors 19 on the suction plate 20 are adsorbed in the groove 17, and the mechanical arm 3 then transports the scissors 19 on the suction plate 20 to the next process, and then increases the hydraulic pressure in the hydraulic cylinder 12, and the piston rod drives the lifting plate 10 rises, the fixed rod 13 rotates at the stop block 8, drives the collection rod 9 in the stop groove 16 to turn over, and the scissors blade 19 slides out from the fixed post 18, takes off from the collection rod 9 and places it in the corresponding position.

[0029] During installation, the fixed plate 6 is first placed on the cross bar 5 and aligned, then the fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com