Paper mill paper pulp pulping equipment and electrical control system thereof

A technology for pulping in paper mills, applied in the field of pulping equipment and electrical control systems in paper mills, can solve the problems of uneven pulping, slow pulping, cumbersome operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

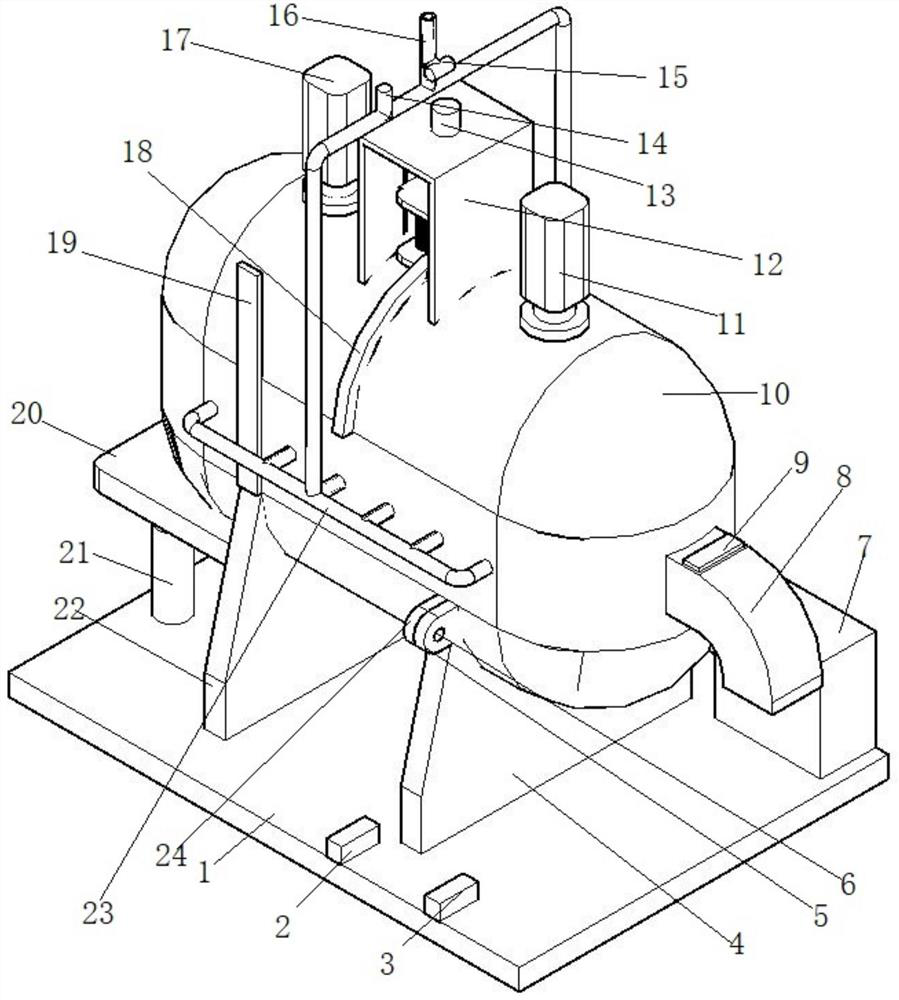

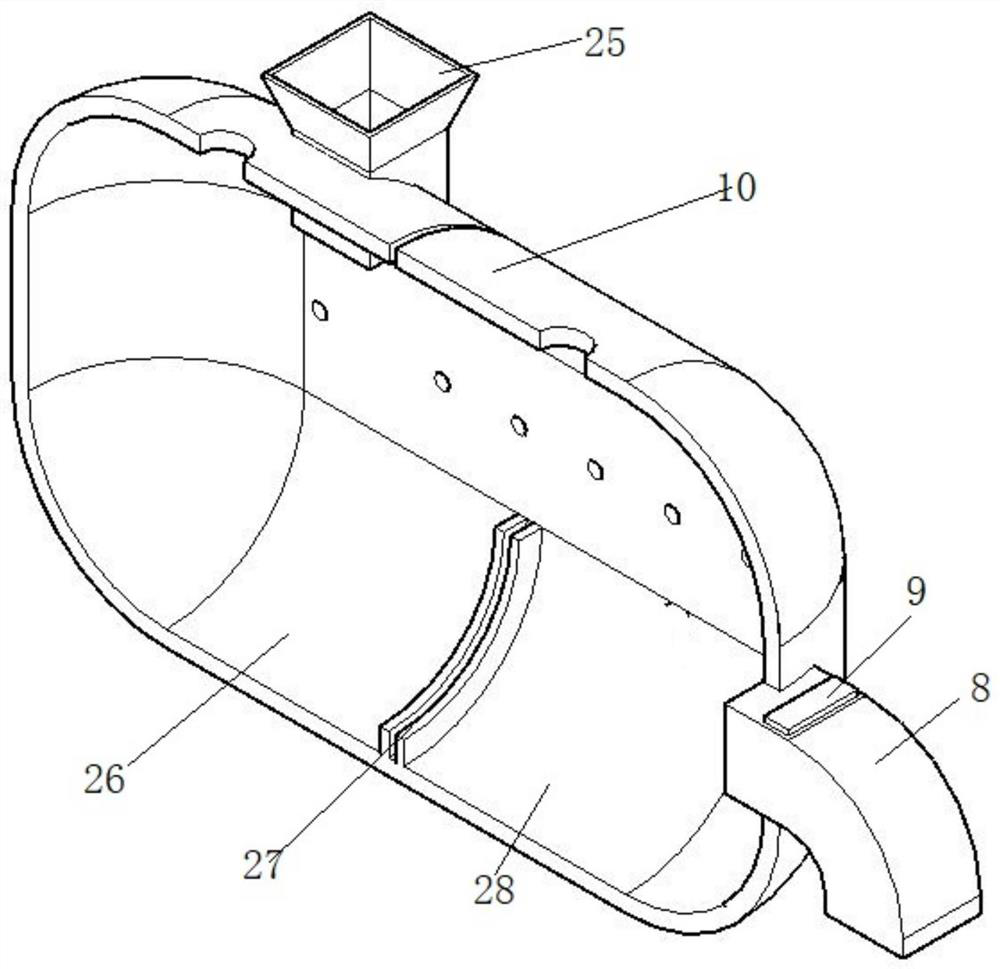

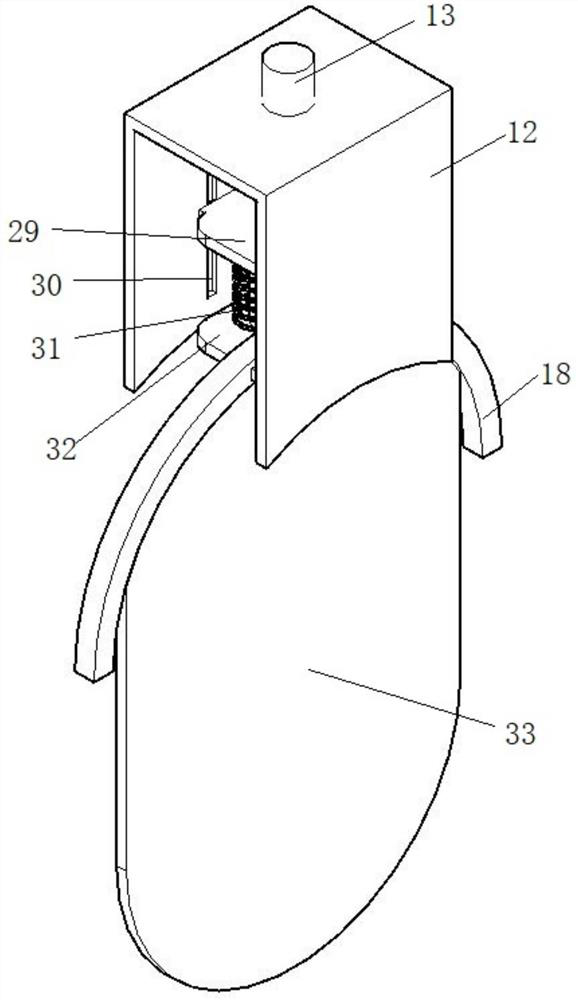

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0027] Such as Figures 1 to 7 As shown, this embodiment provides a kind of pulping equipment in a paper mill, including a bottom plate 1, and the top of the bottom plate 1 is fixed with two symmetrically arranged support plates a4 and support plates b22, and the support plate a4 is axially connected There is a slurry tank 10, and the other end of the slurry tank 10 is erected on the support plate b22, and the inside of the slurry tank 10 is divided into a primary slurry chamber 26 by a partition 33 driven by a driver electrically connected to the controller 7 and a secondary pulping chamber 28, the inner wall of the primary pulping chamber 26 is provided with an agitator driven by a motor a17, and the inside of the secondary pulping chamber 28 is provided with a shear driven by a motor b11, so The top of the pulping tank 10 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com