Sewing device

A technology of sewing and assembly department, which is applied in the direction of sewing machine control devices, sewing equipment, sewing machine components, etc., and can solve the problem of time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

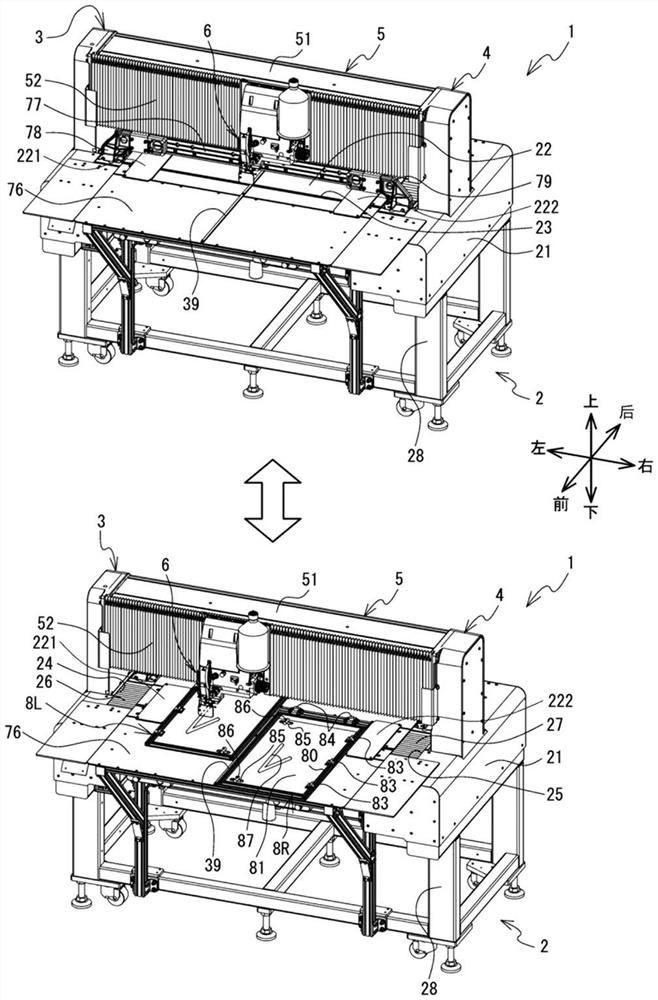

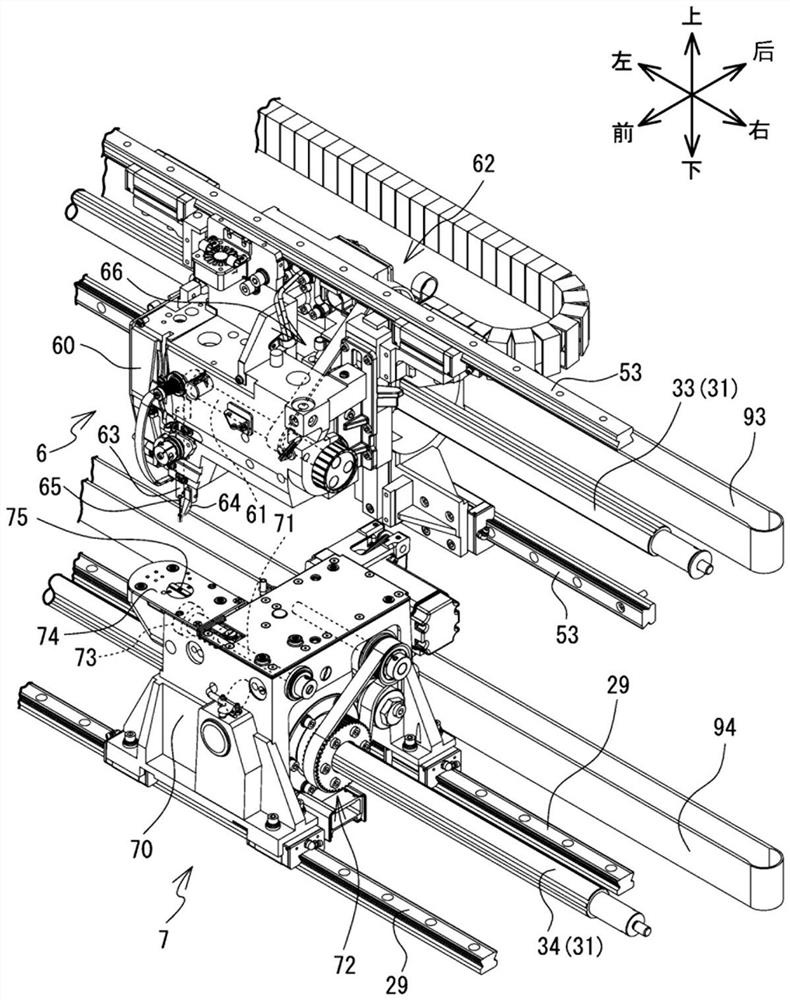

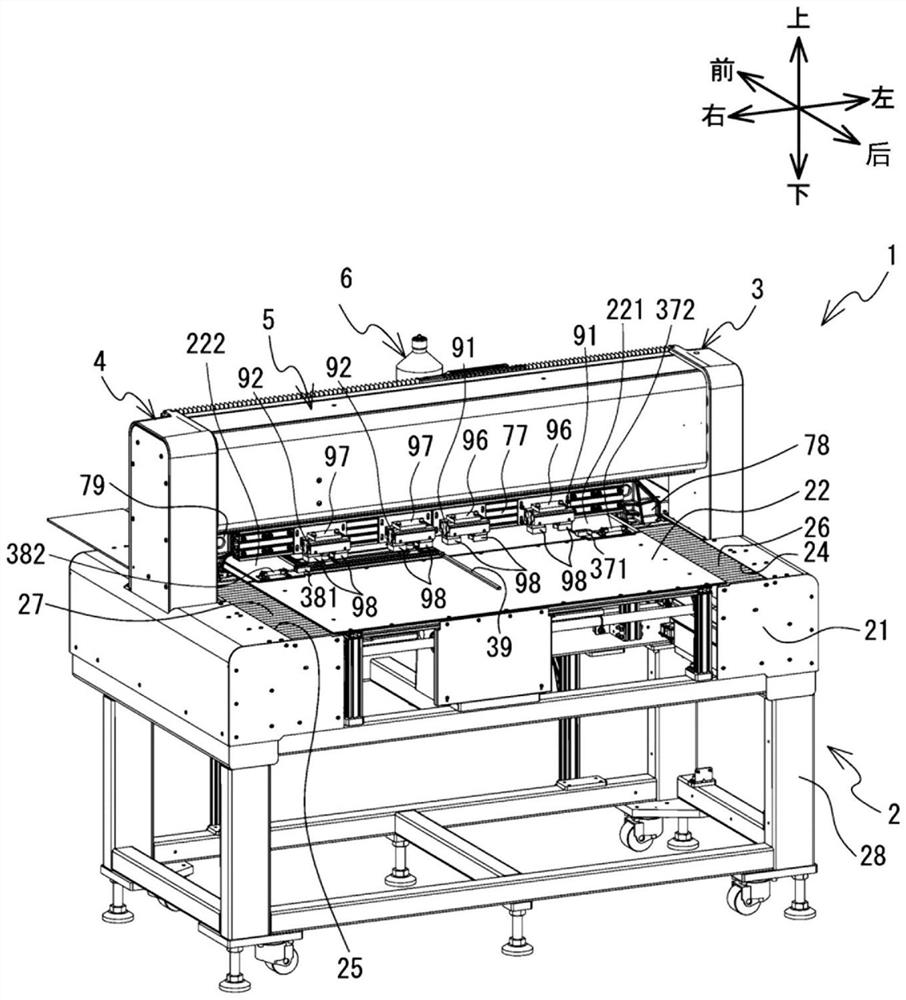

[0033] The physical structure of the sewing apparatus 1 of the first embodiment and the second embodiment of the present invention will be described. The following description will be used in the appended and back and up and down. like Figure 1 ~ 8 As shown, the sewing apparatus 1 is a gate sewing apparatus having a seat portion 2, a strut portion 3, 4, a beam portion 5, a needle rod mechanism 6, a upper and lower mechanism 66, a shuttle mechanism 7, a holding mechanism 8L, 8R, and movement Institution 9 (see Figure 8 ), Conveying mechanism 10 (refer to Figure 8 ), First sensor 37 (refer to Figure 8 ), The second sensor 38 and the operating portion. figure 1 , Figure 4 and Figure 7 The illustration of the first sensor 37 and the second sensor 38 is omitted.

[0034] The base portion 2 has a base portion 21, the placing portion 22, 76, the opening portion 24, 25, the wrinkle portion 26, 27, the casing 28, the lower rail 29, and a pair of rails. The base 21 is a substantially long s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com