Intelligent hot melting sprue device for injection mold

A technology for injection molds and molds, which is applied in the field of intelligent hot-melt gate devices for injection molds. It can solve the problems of destroying the toughness of injection molded parts and the inconsistency of the melting state of injection molding raw materials, so as to ensure long-term use, avoid solid residues, and improve processing quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

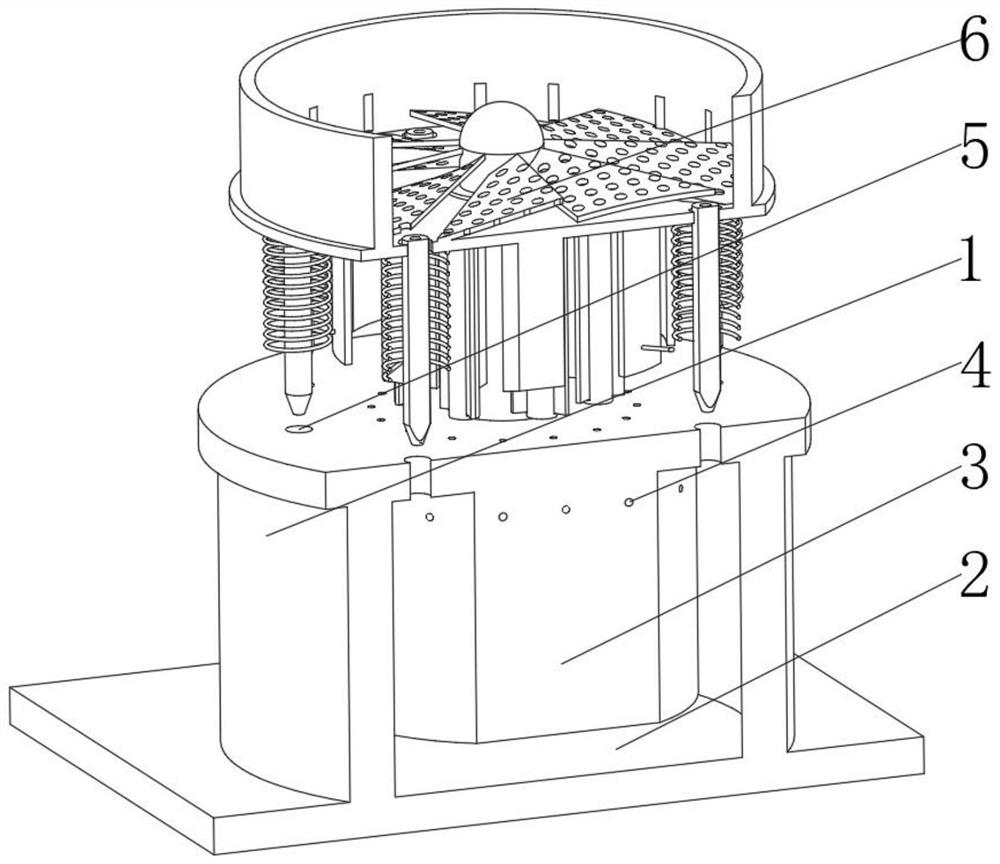

[0039] see Figure 1-2 , the present invention provides a technical solution: an intelligent hot-melt gate device for injection molds, specifically comprising:

[0040] Bottom mold 1, the bottom mold 1 has a barrel mold, and a mold seat plate 2 fixed on the bottom of the barrel mold, and a top mold 3 arranged in the inner cavity of the barrel mold, and capillary holes provided on the outer surface of the top mold 3 4, and the injection gate 5 located on the outside of the capillary hole 4 on the top mold 3, and the gate mechanism 6 installed in the middle of the top of the top mold 3, through the L-shaped pipeline design of the capillary hole 4 itself, it is convenient for the gas to flow in the horizontal layer Rapid flow on the upper surface is convenient to discharge the internal gas and avoid the phenomenon of air bubbles in the injection mold due to the residual gas. At the same time, the vertical design of the capillary hole 4 and the injection molded part is convenient to...

Embodiment 2

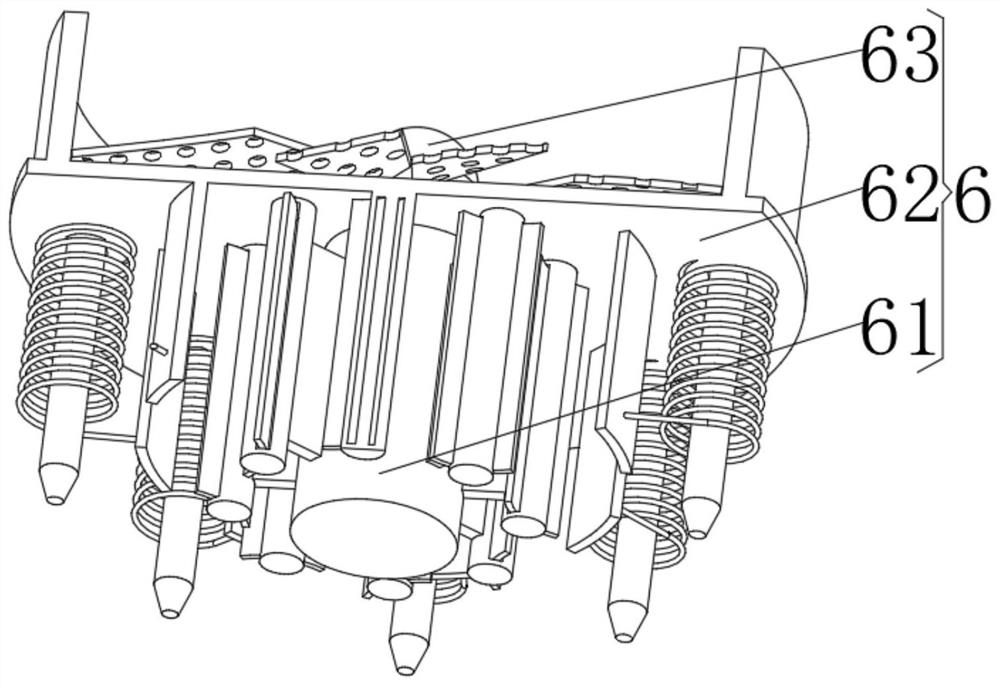

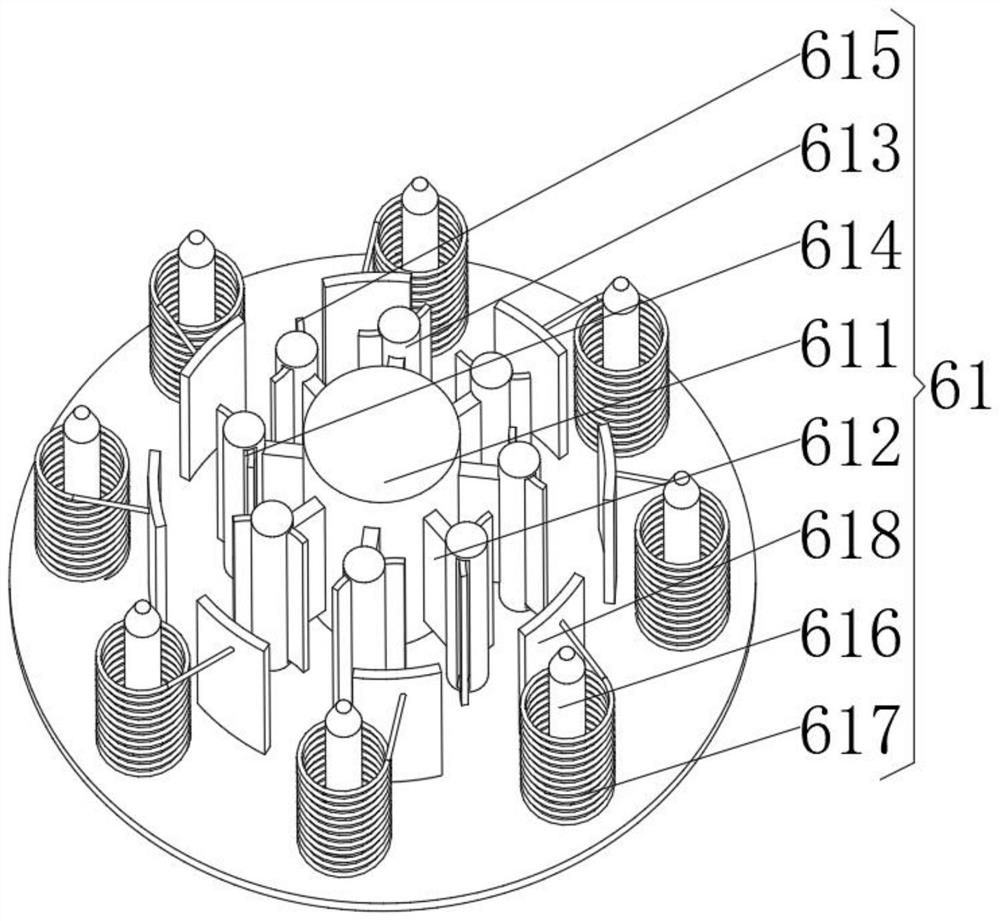

[0045] see Figure 1-3 , On the basis of Embodiment 1, the present invention provides a technical solution: the hot-melt mechanism 61 includes:

[0046] A rotator 611, the rotator 611 has a columnar body, a mounting plate 612 fixed on the outer surface of the columnar body, a magnetic column 613 fixed on the other side of the mounting plate 612, and a through slot 614 in the middle of the magnetic column 613 , and the offset wind deflector 615 arranged in the inner cavity of the through groove 614; the position of the magnetic field is changed by the rotation of the magnetic column 613 component, and the component is powered by the magnetoelectric effect, which saves energy and reduces energy consumption At the same time, the inclination design of the offset wind deflector 615 allows the airflow to diffuse outwards, dissipates air to some components, and ensures the long-term use of the components.

[0047] Injection sprue tube 616, the injection sprue tube 616 has a cylinder...

Embodiment 3

[0051] see Figure 1-4 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the injection gate tube 616 includes:

[0052] A cylinder column A1, the cylinder column A1 has an angular column cylinder, and a staggered fan plate A2 arranged on the inner surface of the angular column cylinder, and an axis column A3 installed in the center of the staggered fan plate A2;

[0053] A driver A4, the driver A4 has a motor body and a fixed wheel A5 fixed on the top of the column A1, and the motor body passes through the column A1 and extends to the inner cavity of the column A1. Through the rotation of the staggered fan plate A2, the injection molding melt flows slowly, avoiding the rapid flow of the injection molding melt and causing bubbles inside, and at the same time diverting the injection molding melt so that it flows along the inner wall, better for the interior The airflow is pressurized and discharged, while better shaping.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com