Vickers hardness test auxiliary device

An auxiliary device, the technology of Vickers hardness, applied in the direction of measuring device, testing material hardness, strength characteristics, etc., can solve the problems of cumbersome operation, inconvenient clamping and fixing, etc., to achieve the effect of improving efficiency, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

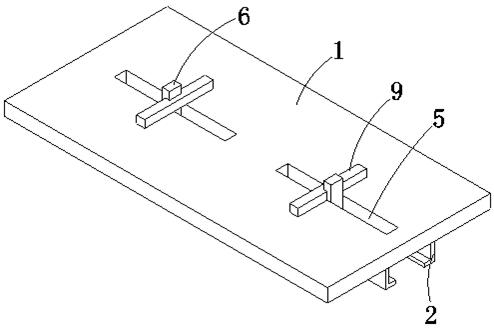

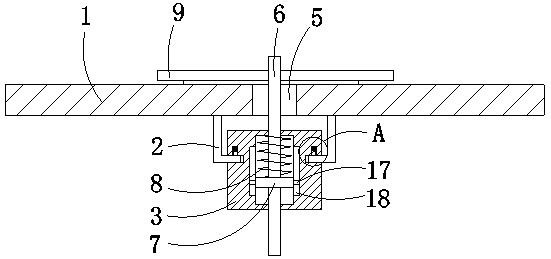

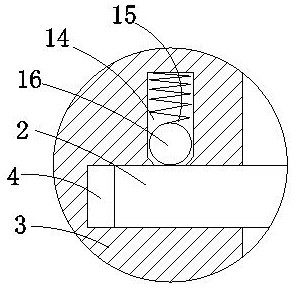

[0023] Such as Figure 1 to Figure 4 As shown, a kind of Vickers hardness test auxiliary device described in the present invention comprises test bench 1, cylinder body 3 and replaceable splint 9, and described cylinder body 3 is provided with two groups, and in described test bench 1 The top is provided with two corresponding bar-shaped holes 5, and the bottom of the test bench 1 is fixedly connected with a slide rail 2 corresponding to the bar-shaped holes 5, and the outer surface of the cylinder body 3 is provided with a The chute 4 matched with the slide rail 2, the cylinder body 3 is slidably connected to the inside of the slide rail 2 through the chute 4, and the two groups of cylinder bodies 3 are respectively located directly below the corresponding bar-shaped holes 5, and pass through the set slide rail 2. It is convenient for the cylinder body 3 to move in the slide rail 2, so as to adjust the position of the splint 9; inside the cylinder body 3, there is a linkage r...

Embodiment 2

[0027] Such as Figure 5 As shown, the difference from Embodiment 1 is that an opening 10 is provided on the upper end side of the linkage rod 6, and the splint 9 is inserted into the inside of the opening 10, and the top of the splint 9 is provided with a The through hole 19 of the linkage rod 6 extends to the outside of the splint 9 through the through hole 19 in the splint 9 , and one of the inner sides of the through hole 19 is inserted into the opening 10 in the linkage rod 6 . When replacing the splint 9 , put the splint 9 on the outside of the linkage rod 6 through the through hole 19 , and then push the splint 9 to be inserted into the opening 10 , which is beneficial to restrict the splint 9 on the linkage rod 6 .

[0028]Adopting a Vickers hardness test auxiliary device according to the present invention, its working principle is: when in use, according to the width of the sample plate, first replace the splint 9, and then move the two groups of cylinders 3 in the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com