Fabricated type building module pouring device

A prefabricated and architectural technology, which is applied in the direction of supply devices, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of uneven concrete, uneven strength of prefabricated modules, and high labor intensity, and achieve the effect of uniform and fine concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

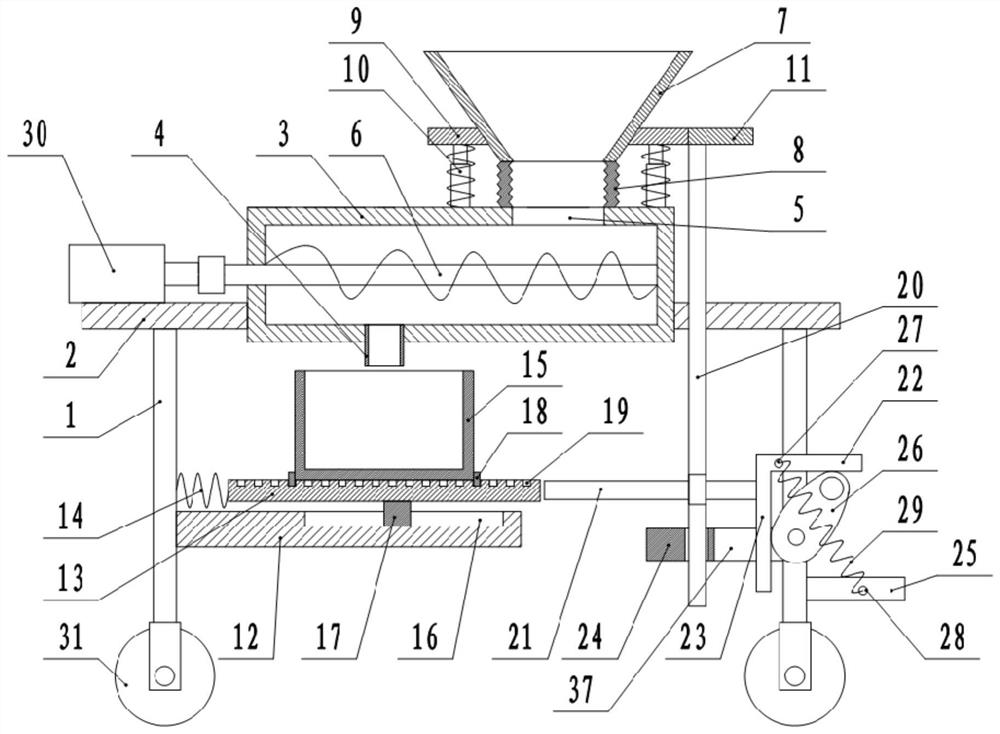

[0029] The embodiment is basically as attached figure 1 Shown: an assembly type building module pouring device, including a frame 1, the top of the frame 1 is vertically welded and fixed with a connecting plate 2, and in this embodiment, a traveling wheel 31 is connected to the bottom of the frame 1.

[0030] Connecting plate 2 is connected with mixing tank 3, and in this embodiment, mixing tank 3 and connecting plate 2 are fixed by bolts, and mixing tank 3 is provided with stirring unit, and mixing unit comprises stirring bar 6 and driving motor 30 in the present embodiment, drives The motor 30 is located on the connecting plate 2 . The stirring rod 6 is welded and fixed with a spirally arranged stirring knife, one end of the stirring rod 6 is rotatably connected with the side wall of the mixing tank 3 through a bearing, and the other end of the stirring rod 6 extends out of the mixing tank 3 and is connected to the drive motor 30 through a shaft coupling fixed.

[0031] Th...

Embodiment 2

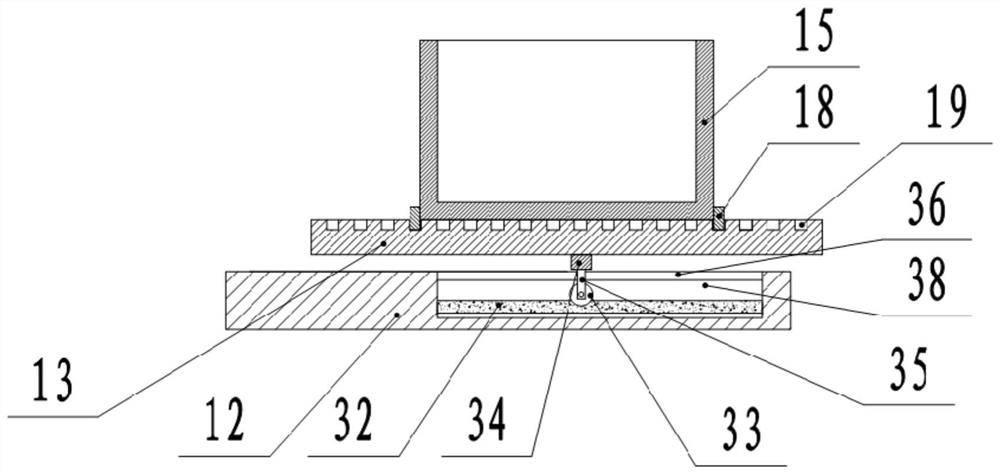

[0047] Such as figure 2 with image 3 As shown, a prefabricated building module pouring device differs from the first embodiment in that the sliding fit structure between the sliding plate 13 and the fixed plate 12 in this solution is different from that in the first embodiment, specifically: in this embodiment A sliding cavity 38 is provided on the fixed plate 12, and a bar-shaped hole 36 communicating with the sliding cavity 38 is opened on the top of the fixed plate 12. The width of the bar-shaped hole 36 is smaller than the width of the sliding cavity 38.

[0048] The bottom end of the sliding plate 13 is welded and fixedly connected with a moving block 34, the width of the moving block 34 is greater than the width of the strip hole 36, and the moving block 34 is positioned above the fixed plate 12, and the bottom end of the moving block 34 is fixedly connected with a support plate 35 by screws. , the bottom end of the support plate 35 extends into the slide chamber 38 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com