A new type of lithium battery fire extinguishing agent and preparation method thereof

A lithium battery and fire extinguishing agent technology, applied in fire protection equipment, chemical instruments and methods, other chemical processes, etc., can solve the problems of poor cooling rate, temperature reduction, weak oxygen isolation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

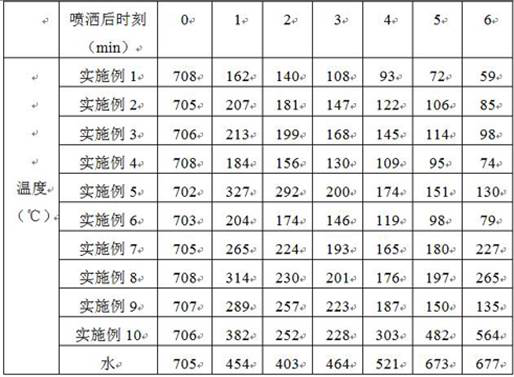

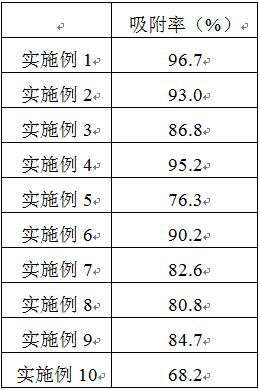

Examples

Embodiment 1

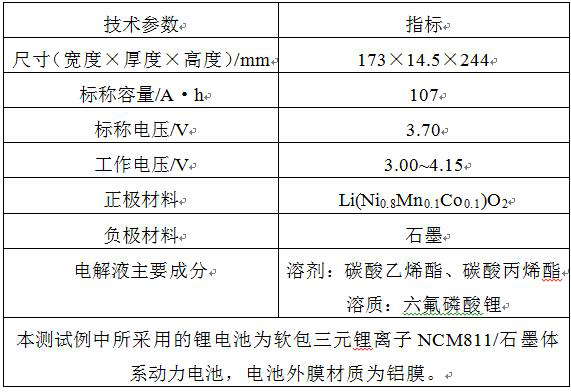

[0057] A novel lithium battery fire extinguishing agent consists of the following raw materials in parts by weight:

[0058] 6 parts by weight of flame retardant, 12 parts by weight of adsorbent, 6 parts by weight of sodium bicarbonate, 20 parts by weight of foaming agent, 12 parts by weight of foam stabilizer, and 44 parts by weight of water.

[0059] The flame retardant is a mixture of (trimethylsilyl) phosphite and zinc borate in a mass ratio of 7:1.

[0060] The adsorbent is a mixture composed of aluminum hydroxide, activated carbon and denatured vermiculite in a mass ratio of 8:4:17.

[0061] The foaming agent is a mixture of cetyl sulfobetaine and 3-sulfopropyldodecyldimethylbetaine in a mass ratio of 5:3.

[0062] The foam stabilizer is a mixture of ethylene glycol, triethylene glycol monobutyl ether and tetraethylene glycol monobutyl ether in a mass ratio of 1:3:2.

[0063] The preparation method of described novel lithium battery fire extinguishing agent is made up ...

Embodiment 2

[0072] It is basically the same as Example 1, the difference is:

[0073] The preparation method of described denatured vermiculite is:

[0074]N1 uses a planetary ball mill to mill the vermiculite with a wet milling method to obtain vermiculite powder with a particle size of 1100 mesh; in the ball milling process, two sizes of zirconia balls with diameters of 0.9mm and 1.7mm are used Mix with a mass ratio of 1:2, the ball-to-material ratio is 17:1, the rotating speed of the planetary ball mill is 800r / min, the ball milling time is 18h, and the wet grinding aid is polyoxyethylene sorbitan monooleate, water A mixture composed of a mass ratio of 1:7, the mass ratio of the wet grinding aid to the vermiculite is 1.8:1; after the ball milling is completed, the precipitate A is filtered to obtain the precipitate A, and the precipitate A is washed with water and filtered again to obtain the precipitate B, and then Dry the precipitate B at 75°C to obtain the vermiculite powder; the m...

Embodiment 3

[0078] It is basically the same as Example 1, the difference is:

[0079] The preparation method of described denatured vermiculite is:

[0080] N1 uses a planetary ball mill to mill the vermiculite with a wet milling method to obtain vermiculite powder with a particle size of 1100 mesh; in the ball milling process, two sizes of zirconia balls with diameters of 0.9mm and 1.7mm are used Mix with a mass ratio of 1:2, the ball-to-material ratio is 17:1, the rotating speed of the planetary ball mill is 800r / min, the ball milling time is 18h, and the wet grinding aid is polyoxyethylene sorbitan monooleate, water A mixture composed of a mass ratio of 1:7, the mass ratio of the wet grinding aid to the vermiculite is 1.8:1; after the ball milling is completed, the precipitate A is filtered to obtain the precipitate A, and the precipitate A is washed with water and filtered again to obtain the precipitate B, and then Dry the precipitate B at 75°C to obtain the vermiculite powder; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com