Straw pulling and ear picking mechanism of vertical corn harvester header

A technology for corn harvesters and headers, which is applied to headers, harvesters, agricultural machinery and implements, etc., can solve problems such as high manufacturing costs, low operating efficiency, and poor operating quality, and improve operating quality and improve operating quality and efficiency, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in further detail below with reference to the accompanying drawings and examples.

[0027] It should be made that the following detailed description is intended to illustrate the invention and is not intended to limit the invention.

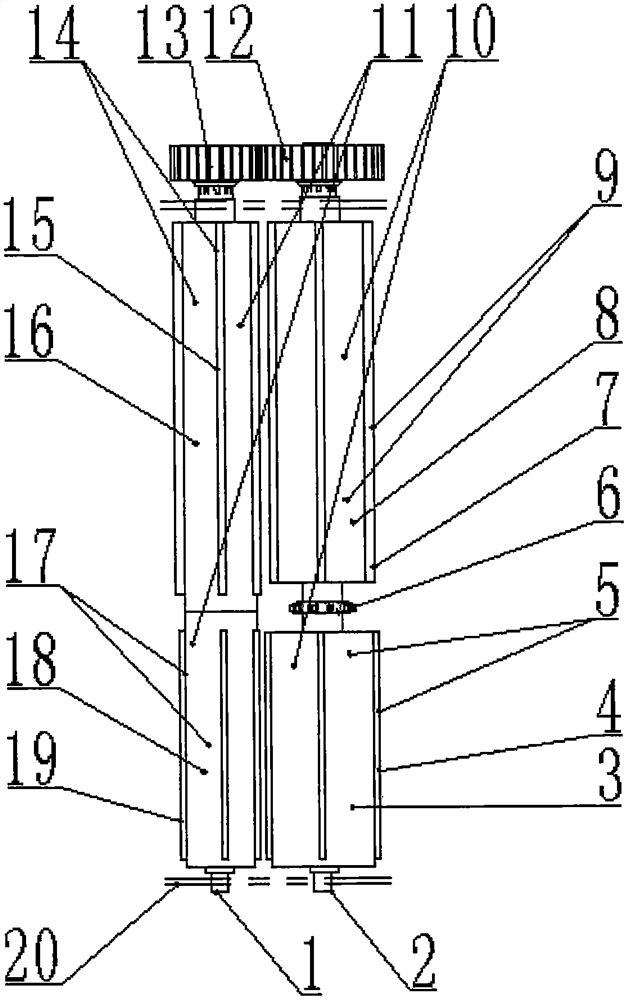

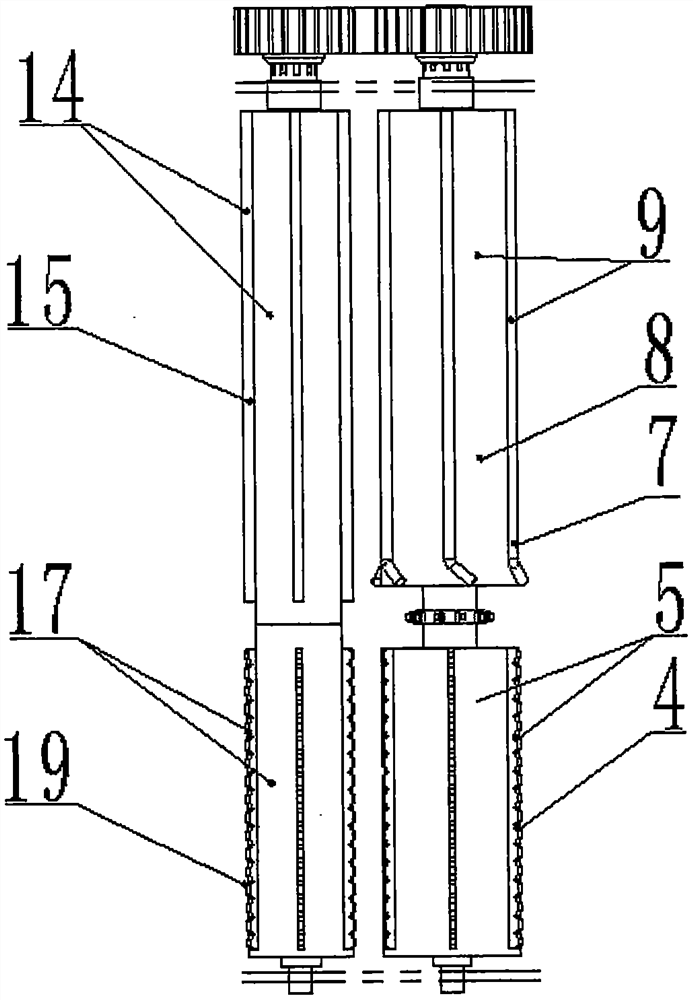

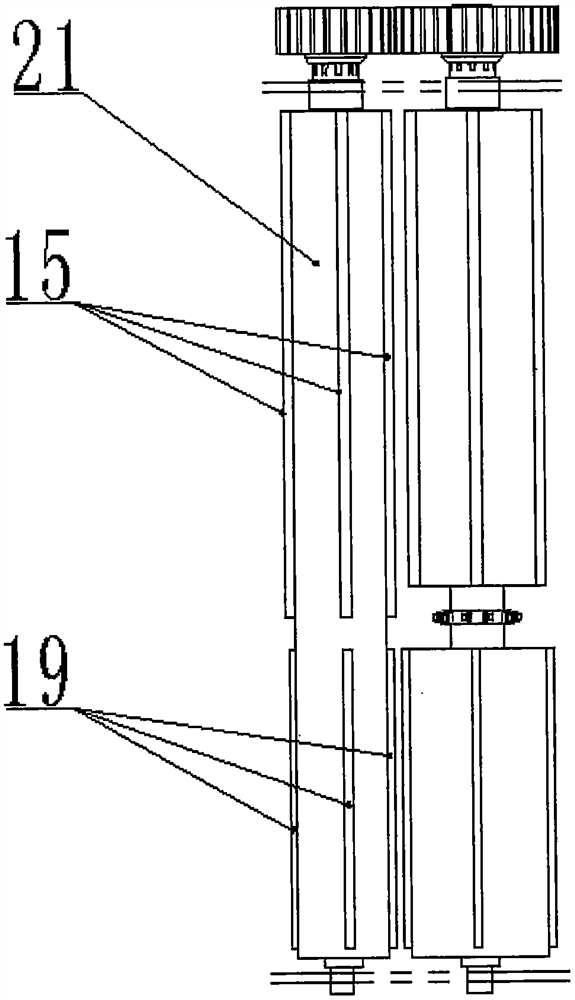

[0028] figure 1 A structural form of the present invention is given. As can be seen from the figure, the present invention is common in consensus prior art in that it is also composed of the drive shafts 2, 1 and the drive gears 12, 13 applied by the main, secondary rollers 10, 11 and their applications. The main and secondary rollers are constructed from the split rolls. Wherein, the main rollers are connected by the upper roller 9, the power sprocket 6, and the lower roller 5, respectively, and the secondary rollers are connected by the upper roller 14 and the lower roller 17, respectively. The upper, lower rollers, and the secondary roller, and the lower roller is composed of a plurality of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com