Yarn discharging and tube replacing integrated device

A technology of lower yarn and tube, applied in textiles and papermaking, etc., to achieve the effect of cost reduction, good rhythm and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

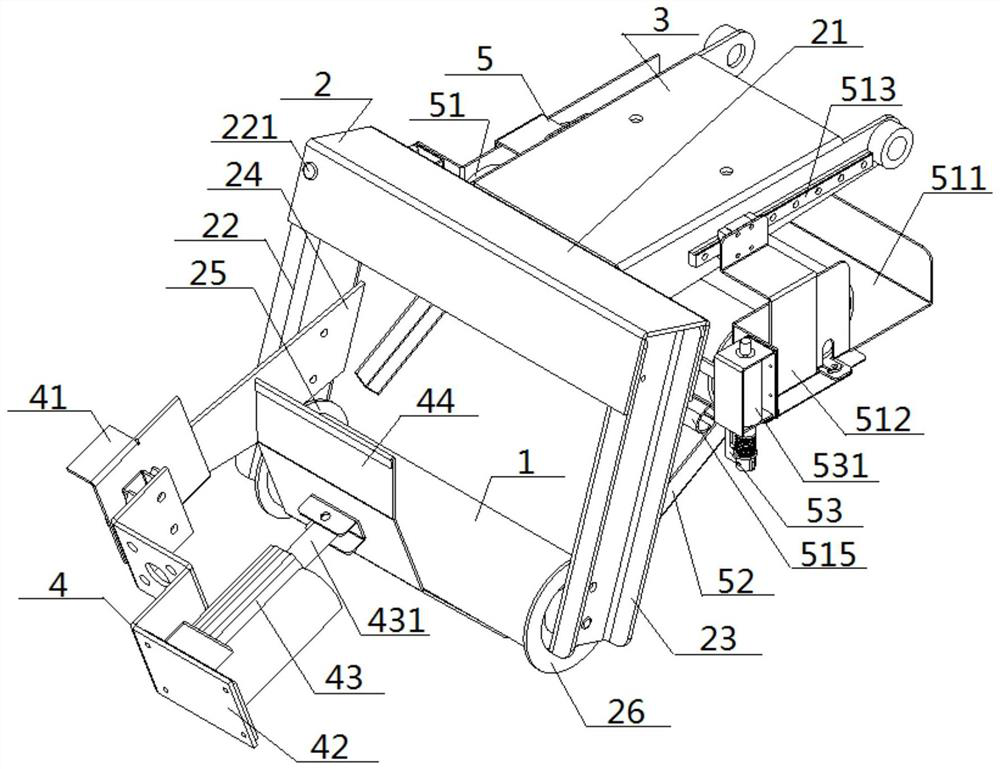

[0062] see figure 1 — Figure 8 , an integrated device for bobbin changing, comprising a winding bobbin clamp 2, a bobbin clamp connecting plate 3, a yarn lowering unit 4 and an empty tube storage unit 5, the winding bobbin clamp 2 includes a clamping top beam 21, a movable side The arm 22 is connected to the fixed side arm 23, the rear end of the clamping beam 21 is connected to the front end of the bobbin clamp connecting plate 3, and the two ends of the clamping beam 21 are respectively connected to the top of the movable side arm 22 and the fixed side arm 23. , the top of the movable side arm 22 is hinged with the top crossbeam 21, the bottom ends of the movable side arm 22 and the fixed side arm 23 are respectively provided with a movable insert 25 and a fixed insert 26, and the movable insert 22 is close to the movable insert. 25 is connected with the inner end of the oblique handle 24, and the outer end of the oblique handle 24 extends away from the movable side arm 22...

Embodiment 2

[0065] Basic content is the same as embodiment 1, the difference is:

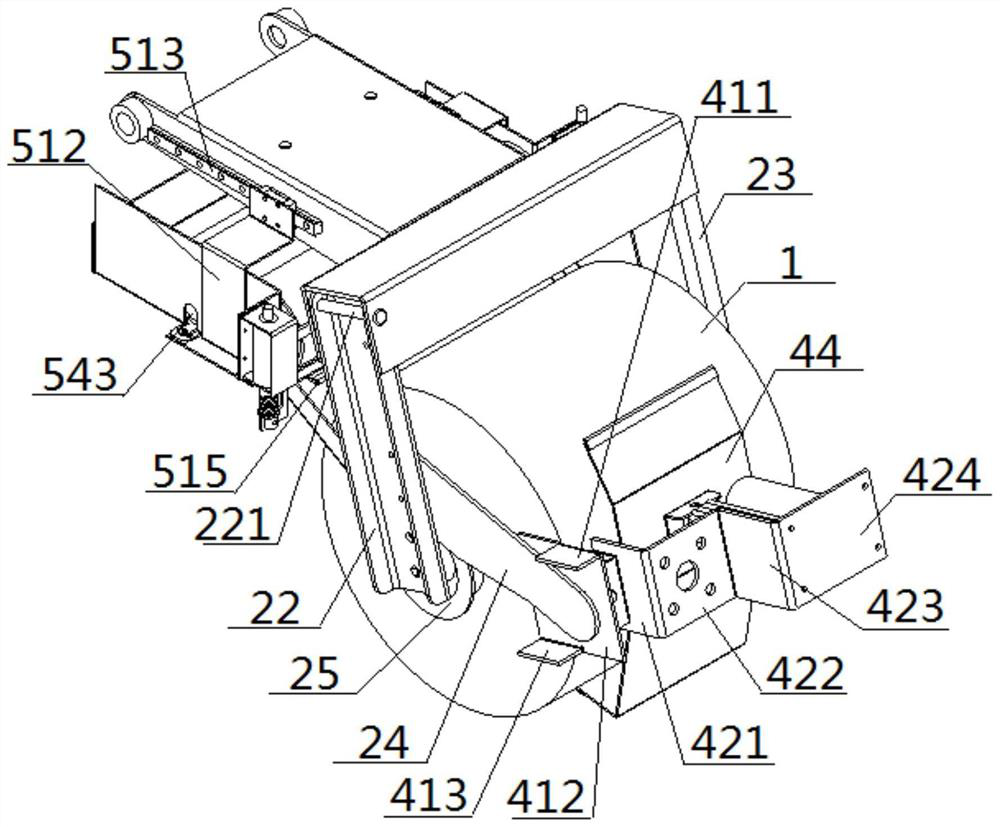

[0066] The outer gripper 41 includes an upper gripping plate 411, a middle gripping plate 412 and a lower gripping plate 413, the inner end of the upper gripping plate 411 is vertically connected with the top of the middle gripping plate 412, and the inner end of the lower gripping plate 413 is connected with the middle gripping plate 413. The bottom end of gripping plate 412 is vertically connected, and the outer ends of upper gripping plate 411 and lower gripping plate 413 all extend toward the direction away from lower yarn base plate 42, and the central axis connecting line between upper gripping plate 411 and lower gripping plate 413 is The projection on the middle grip plate 412 is an oblique line. The lower yarn base plate 42 is a stepped structure, including a vertical plate 421, a flat second plate 422, a vertical third plate 423, and a flat fourth plate 424. Connection, the outer end of the first...

Embodiment 3

[0068] Basic content is the same as embodiment 1, the difference is:

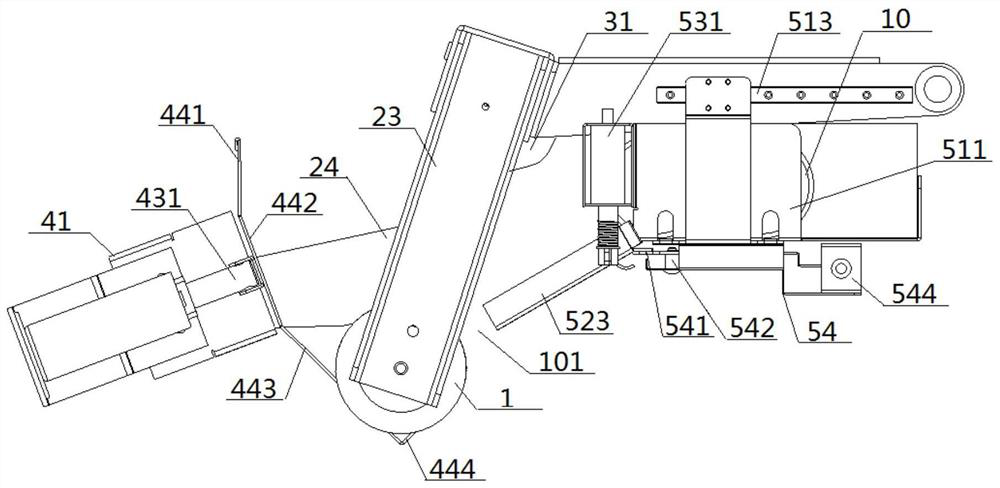

[0069] The concave push plate 44 includes a slanted upper extension plate 441, a vertical middle straight plate 442, an oblique lower extension plate 443 and an upper hook horizontal plate 444. The back side of the vertical middle straight plate 442 is connected with the outer end of the telescopic push rod 431. The top of the middle straight plate 442 is connected with the low end of the inclined upper extension plate 441, the bottom of the vertical middle straight plate 442 is connected with the high end of the inclined lower extension plate 443, and the lower end of the inclined lower extension plate 443 is connected with the bottom of the upper hook horizontal plate 444. Connected, the top of the upper hook horizontal plate 444 is upturned and extended; the inclined upper extension plate 441, the vertical middle straight plate 442, the inclined lower extension plate 443, and the upper hook horizontal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com