Gear shifting assembly

A technology of assembly and shift cables, applied in the field of auto parts, can solve the problems of unsmooth shifting of drivers, increased costs, and low efficiency of shift cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

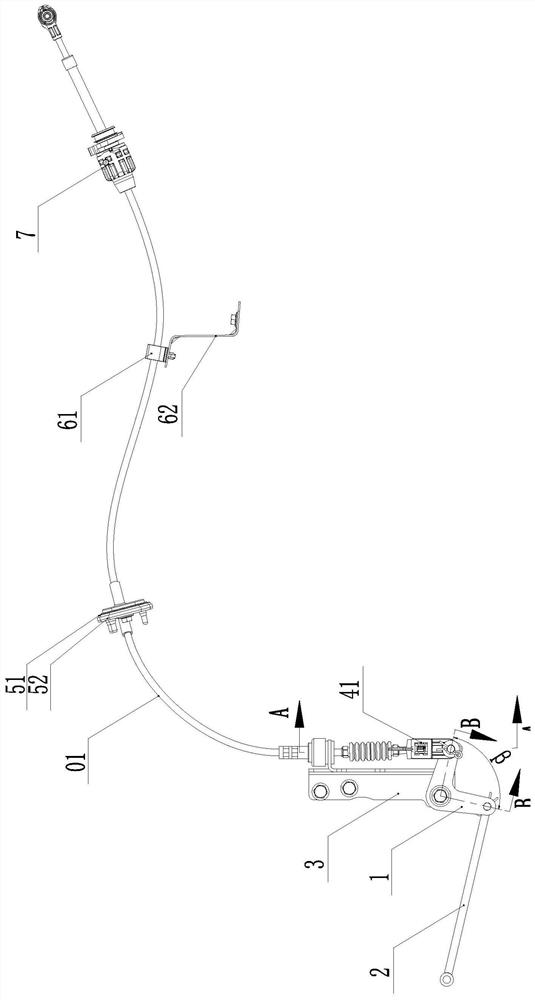

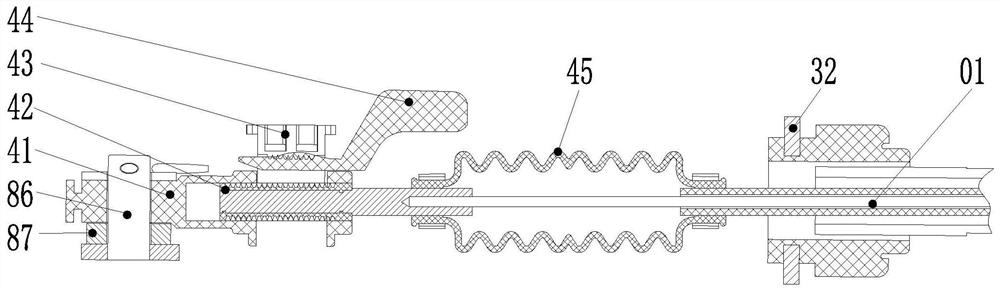

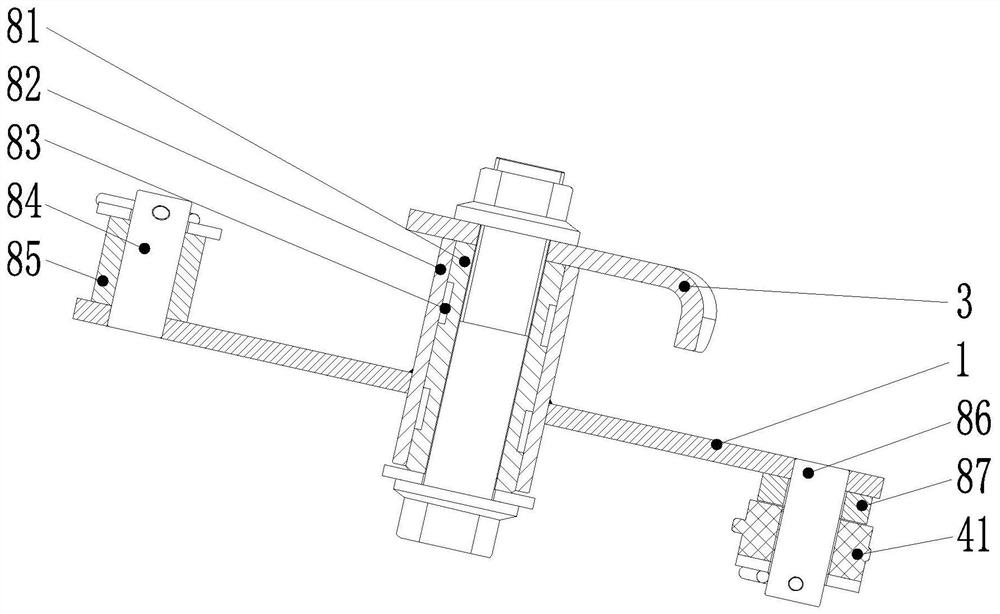

[0032] figure 1 It is a structural schematic diagram of the present invention; figure 2 for the invention figure 1 Schematic diagram of the structure in the A-A direction; image 3 for the invention figure 1 Schematic diagram of the structure in the B-B direction; Figure 4 It is a schematic diagram of the isometric view structure of the present invention, Figure 5 It is a schematic diagram of the top view structure of the present invention, Image 6 It is a structural schematic diagram of the speed change operating mechanism of the present invention, Figure 7 for the invention Image 6 The schematic diagram of the side view structure, Figure 8 for the invention Figure 7 A-A to the structure schematic diagram,

[0033] As shown in the figure, the shift assembly in this embodiment includes a shift cable 01, a mounting bracket 3 and a transfer mechanism, the transfer mechanism includes a power conversion rod 1 and a drive rod 2, and the power conversion rod 1 A le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com