A variable structure dual-mode ram combustor

A ram combustion chamber, dual-mode technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of aircraft loss of control, thrust and momentum changes, etc., to achieve lower performance requirements, smooth transitions, and extended work Mach The effect of number range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following preferred embodiments of the present invention in conjunction with the accompanying drawings are described, i.e., the preferred embodiments described herein are only used to illustrate and explain the present invention, and are not intended to qualify the present invention.

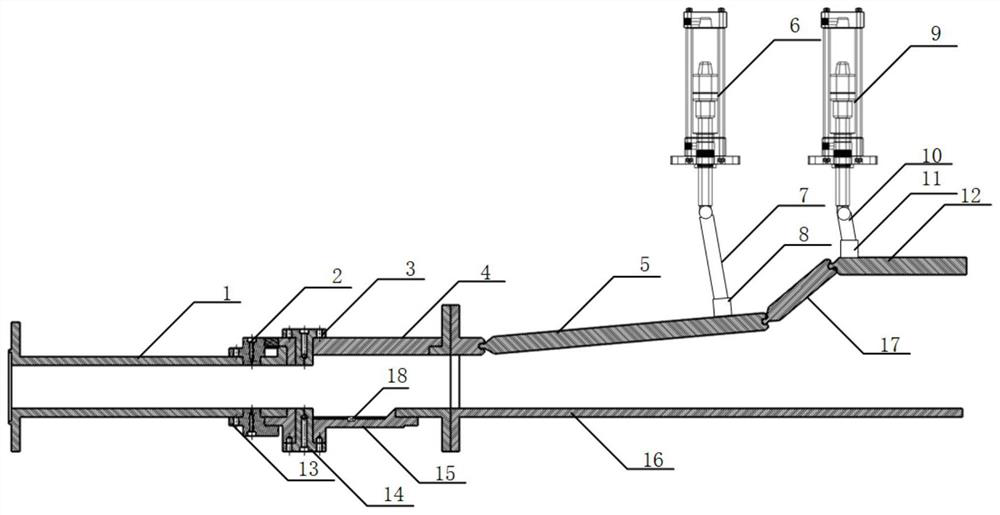

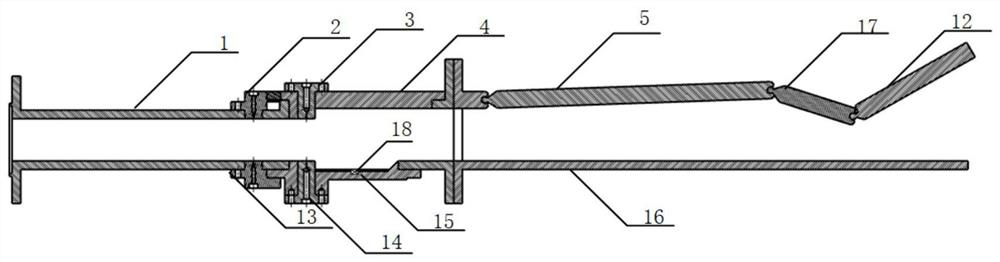

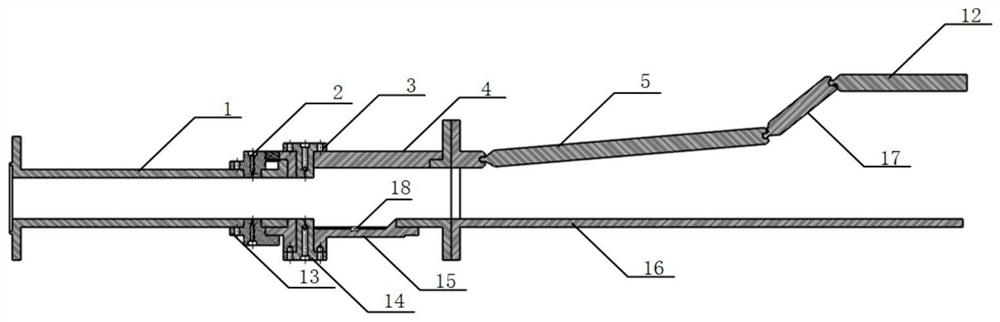

[0031] as Figures 1 to 4 As shown, embodiments of the present invention include a variable structure bimodal combustion chamber consisting of an isolation section 1, a burst expansion section 4, a cavity 15, a lower wall surface of the combustion chamber 16, a first adjustable variable 5, a second adjustable variable 17, a third adjustable variable 12 together. Isolation segments 1 and extrusion section 4 are bolted together. The upper and lower wall pioneer hydrogen injection modules 2, 13 and the upper and lower kerosene injection modules 3 and 13 are bolted to the extrusion section 4, and the first adjustable variant 5, the second adjustable variant 17, the third tunable variant 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com