Rapid breaking structure for over-grouting part of pile top of cast-in-place pile

A technology of cast-in-place piles and pile tops, which can be applied to foundation structure engineering, foundation structure testing, sheet pile walls, etc., can solve problems such as low efficiency, laborious operation, and huge labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

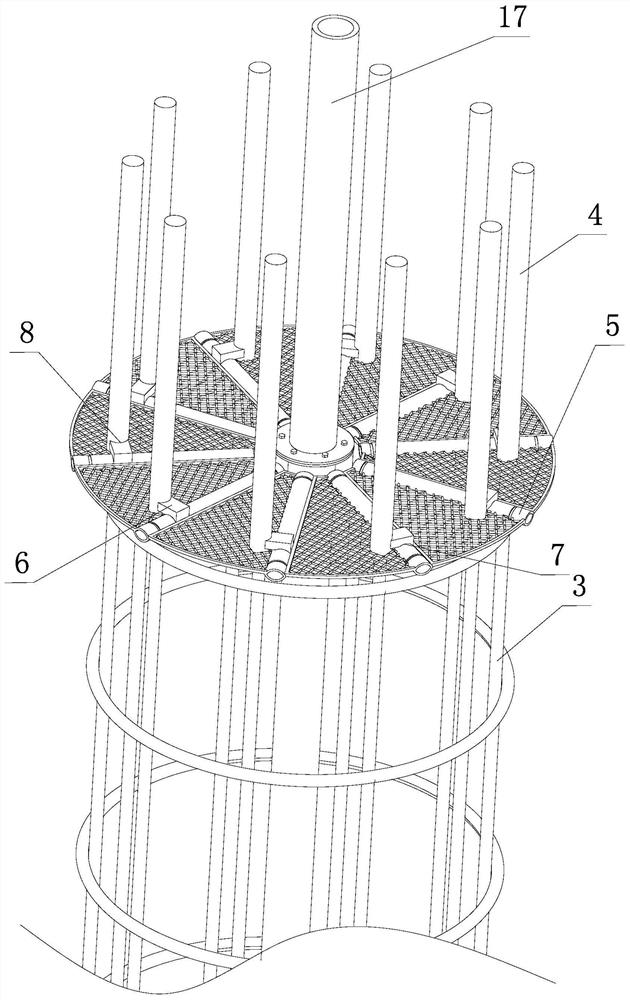

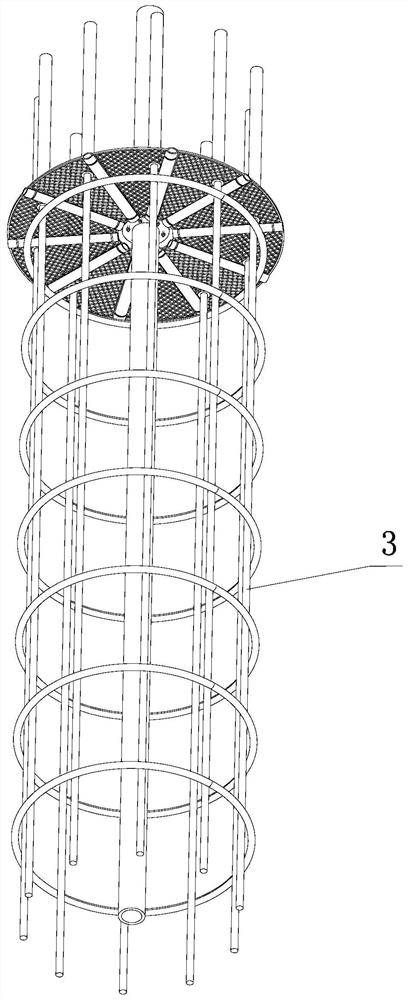

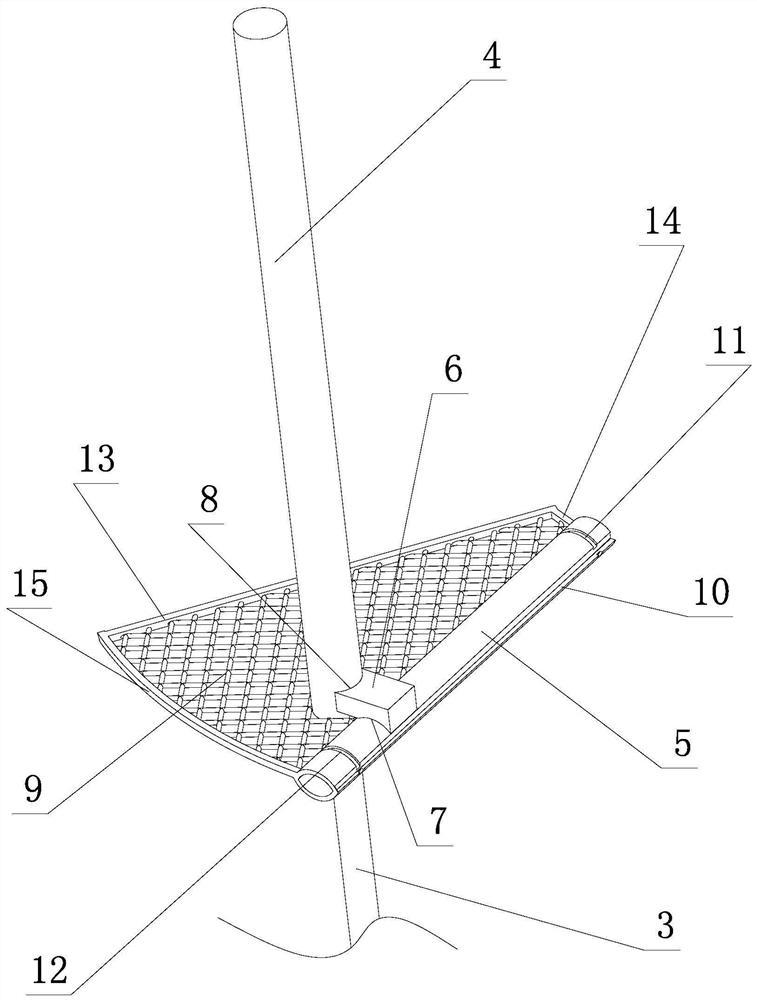

[0022] Such as Figure 1 to Figure 7 Shown, the quick breaking structure of cast-in-situ pile top superfilling part of the present invention, it comprises the pile top superfilling part 1 that will be broken and the remaining normal pile section 2 that is positioned at the pile top superfilling part 1 below after breaking, perfusion The reinforcement cage of the pile includes multiple stirrups and multiple longitudinal main reinforcements 3 in the normal pile section 2, and the reinforcement cage only includes multiple longitudinal main reinforcements 3 without stirrups in the super-filled part 1.

[0023] Each longitudinal main rib 3 of the super-filling part 1 is fitted with a longitudinal sleeve 4 with the opening facing downward; the longitudinal sleeve 4 is coated with insulating substances such as butter or asphalt, and its function is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com