Rigid-flexible coupling fire blast driver and driving method

A rigid-flexible coupling and driver technology, which is used in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of poor controllability of energy release direction and low instantaneous acceleration, and achieve light weight, high safety, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

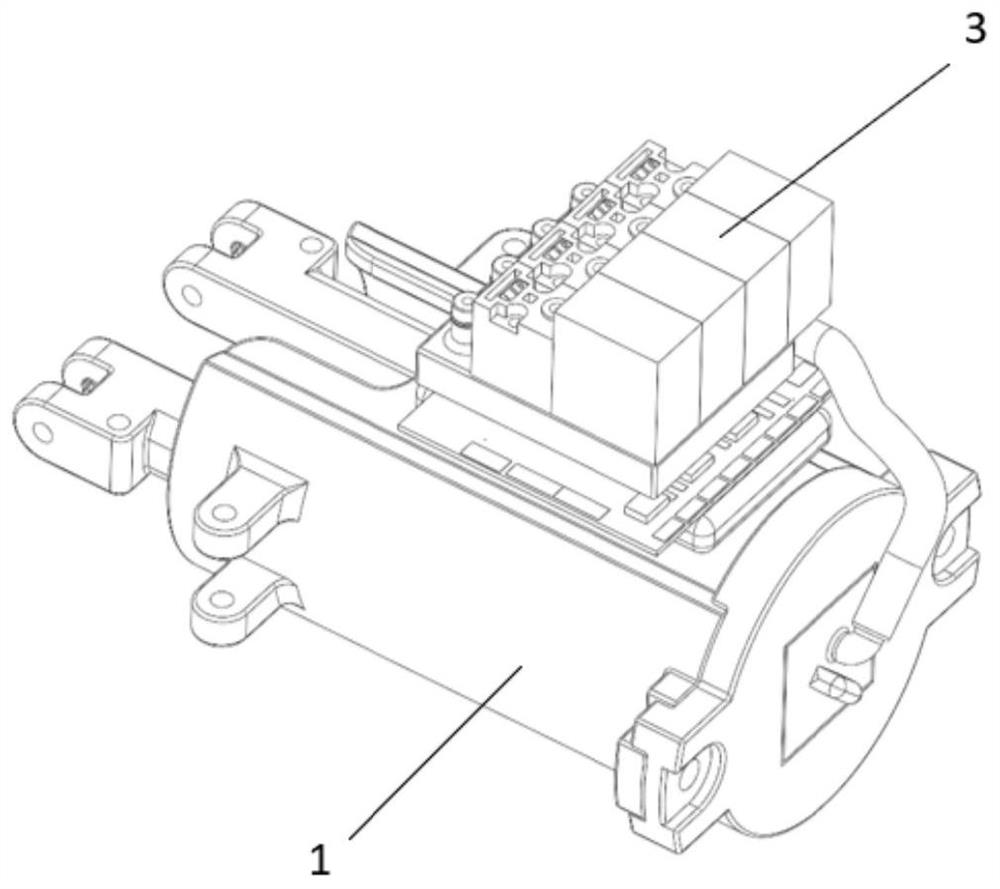

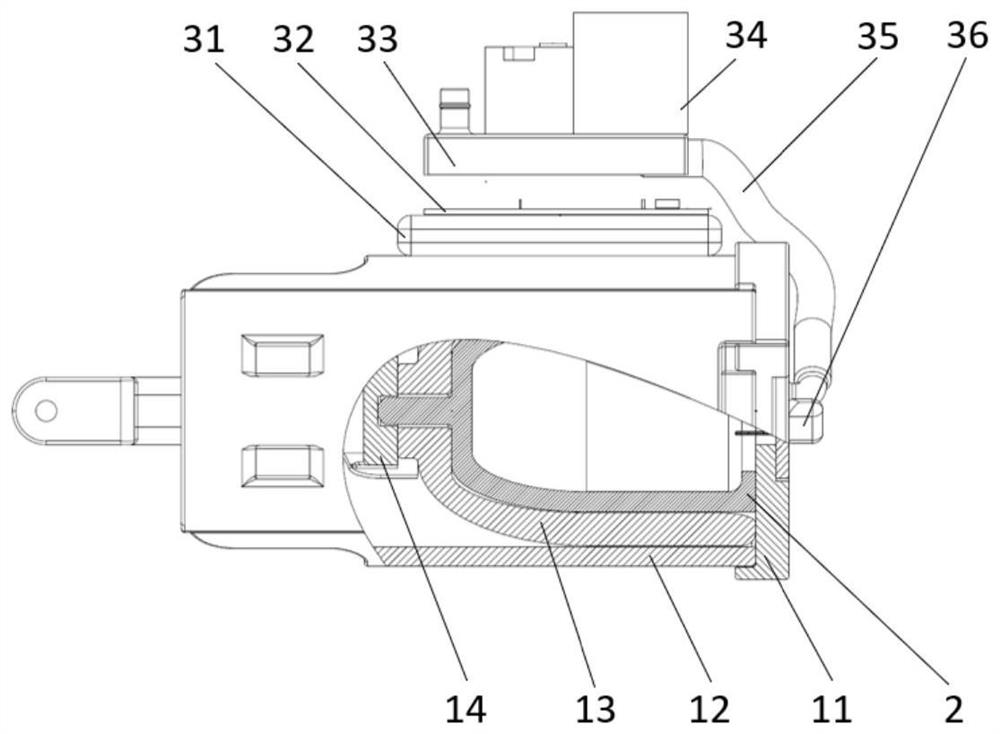

[0025] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment is described. A rigid-flexible coupling detonation driver described in this embodiment includes a rigid piston assembly 1, a soft detonation chamber 2 and a control unit 3. The control unit 3 transports combustible gas into the soft detonation chamber 2. The soft explosion chamber 2 is made of silica gel casting. The soft explosion chamber 2 bears the explosion power and converts the explosion energy into mechanical energy through expansion. The mechanical energy is linearly output by pushing the rigid piston assembly 1 to move.

[0026] The rigid piston assembly 1 includes a cylinder body 12, a rigid piston 13, a rear end cover 11 and a power output part 14, the rear end opening of the cylinder body 12 is provided with a rear end cover 11, and the rear end cover 11 and the cylinder body 12 are connected by bolts. Connection, the rigid piston 13 is arranged in the cylinde...

specific Embodiment approach 2

[0035] Specific embodiment two: a driving method of a rigid-flexible coupling detonation driver described in this embodiment, the method is implemented based on a rigid-flexible coupling detonation driver described in the first embodiment, and the method includes the following steps:

[0036] S1, air extraction: through the circuit board 32 to control the valve island 33 to drain the gas in the software explosion chamber 2;

[0037] S2. Inflating: filling the combustible gas mixed with the valve island 33 into the soft explosion chamber 2;

[0038] S3. Ignition: control the discharge of the ignition head 36 through the circuit board 32, and ignite and explode the combustible gas filled in the soft explosion chamber 2;

[0039] S4. Energy output / conversion: the gas explosion causes the soft explosion chamber 2 to expand, and under the constraints of the rigid piston 13 and the cylinder body 12, the expanded soft explosion chamber 2 pushes the rigid piston 13 to make a linear mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com