Enclosed bus grounding wire device

A technology of closing the bus bar and grounding wire, which is applied to the parts of the connecting device, coupling device, connection, etc., can solve the problems of inability to connect the grounding wire and potential safety hazards, and achieve the effect of fast grounding, good safety and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

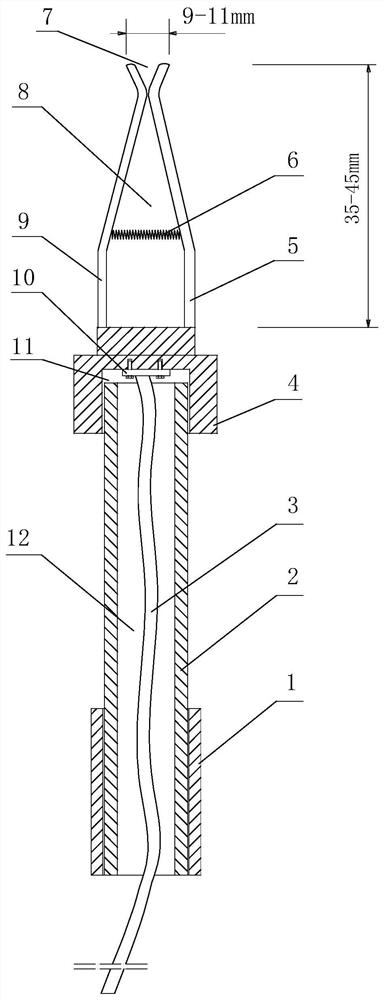

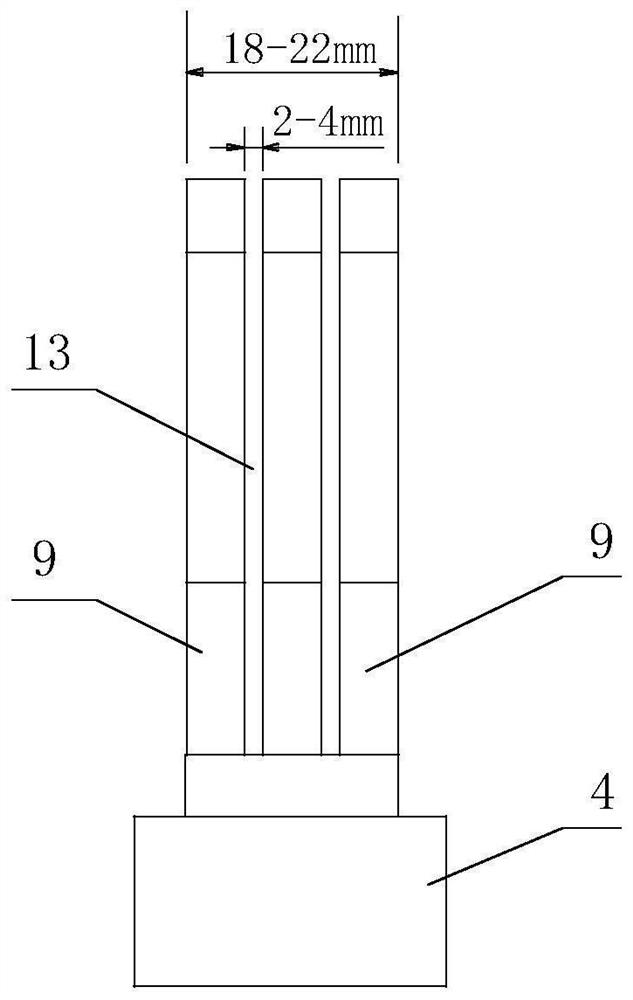

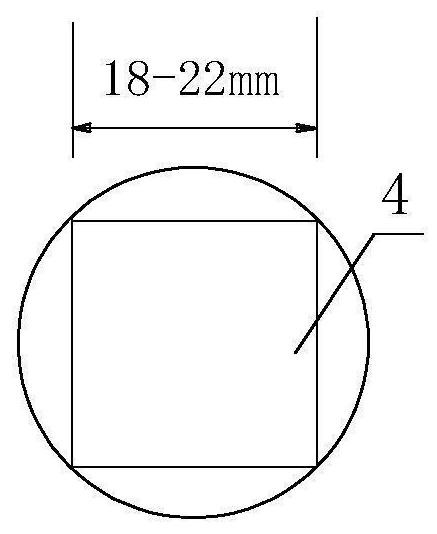

[0016] Such as Figure 1-4 As shown, a closed busbar grounding wire device includes an insulating operating rod 2, a grounding wire 3, and a plug-in conductor; the upper end of the insulating operating rod 2 is provided with an external thread, and the insulating operating rod 2 is provided with a through hole 12; Connecting type conductor comprises conductor connection seat 4, extension spring (spring) 6, left conductor clip 9, right conductor clip 5, and the top of conductor connection seat 4 is cube (cube or cuboid), and the bottom of conductor connection seat 4 is Cylinder, the lower part of the conductor connecting seat 4 is provided with an internally threaded hole 11 for connecting with the insulating operating rod, and the internally threaded hole 11 of the conductor connecting seat 4 is provided with two screw threads for connecting with the grounding wire connecting piece 10 hole; the left side of the upper end surface of the conductor connection seat 4 is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com