Test method for measuring torsion resistance characteristic of flat elevator cable

A technology for elevator cables and test methods, which is applied in the direction of measuring devices, strength characteristics, and the use of stable torsion to test the strength of materials, etc., which can solve problems such as unstable cable operation, shortened core life, and elevator stop accidents

Active Publication Date: 2021-07-06

SHANGHAI NANYANG FUJIKURA CABLE

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] After the elevator cable arrives at the installation site, affected by site conditions and personnel quality, the cable is often twisted and deformed during the installation process. If the deformation is not easy to recover, it is easy to cause the cable After installation, the running state is unstable, leading to hidden dangers and accidents

For example, if the distortion in the construction process cannot be recovered in time, the cable will be twisted after installation. When the cable runs with the car, it will lead to an unstable running track, a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Login to View More

Abstract

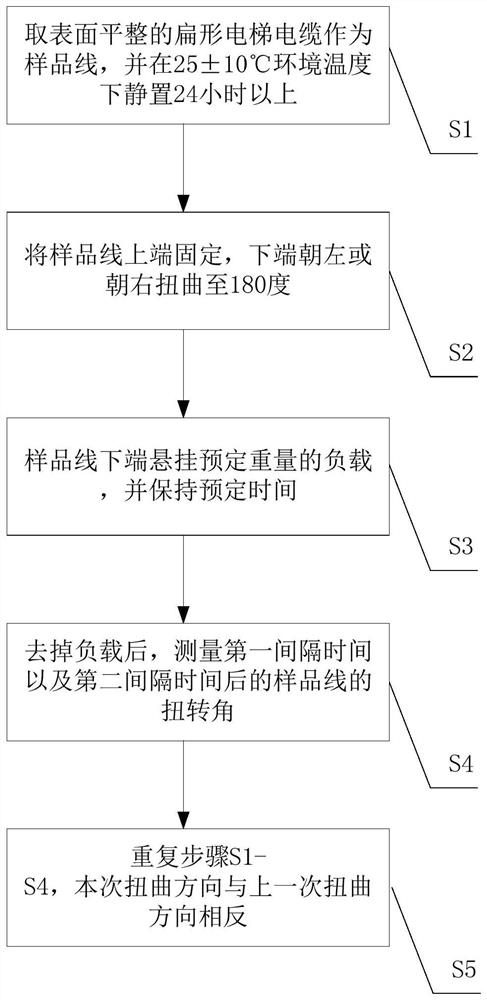

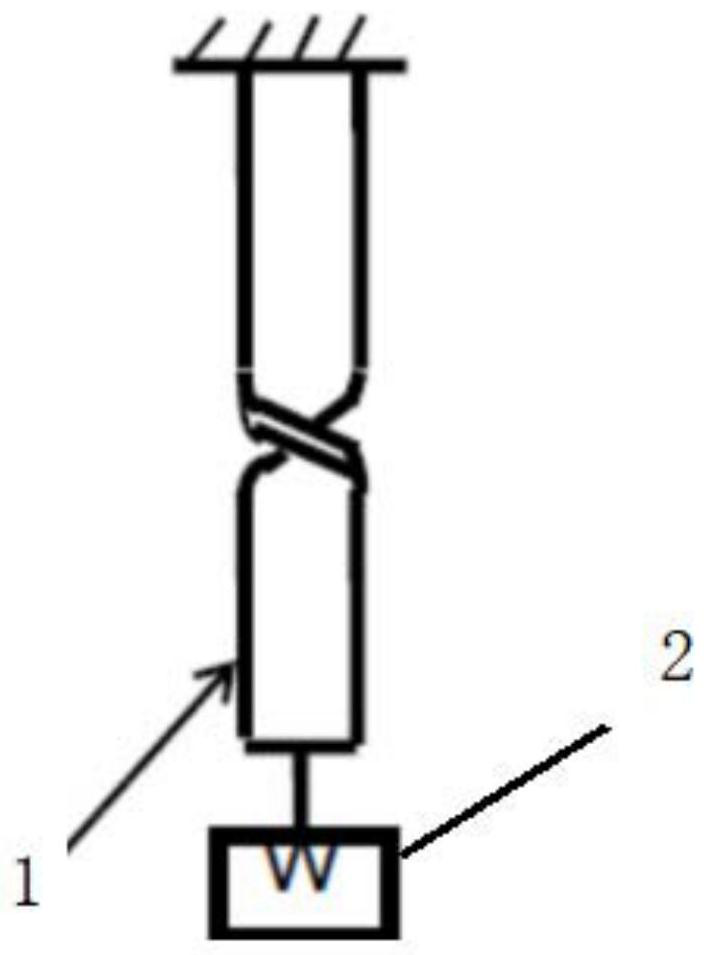

The invention discloses a test method for measuring the distortion resistance characteristic of a flat elevator cable. The test method comprises the following steps: taking a flat elevator cable with a flat surface as a sample, and standing for more than 24 hours at the environment temperature of 25 +/-10 DEG C; fixing the upper end of the sample line, and twisting the lower end of the sample line leftwards or rightwards to 180 degrees; hanging a load with preset weight at the lower end of the sample line for preset time; after the load is removed, measuring torsion angles of the sample line after the first interval time and the second interval time; and repeating the steps S1-S4, and when the step S2 is executed, the current twisting direction is opposite to the previous twisting direction. According to the method, the torsion resistance of the flat elevator traveling cable can be detected.

Description

technical field [0001] The invention relates to a test method for the anti-torsion characteristic of elevator cables. Background technique [0002] After the elevator cable arrives at the installation site, affected by the site conditions and the quality of the personnel, the cable is often twisted and deformed during the installation process. If the deformation is not easy to recover, it will easily lead to unstable operation of the cable after installation, resulting in hidden dangers and accidents. For example, if the distortion during the construction process cannot be recovered in time, the cable will be twisted after installation. When the cable runs with the car, it will lead to an unstable running track, and in severe cases, it will interfere with the hoistway components, resulting in serious elevator stop accidents. At the same time, it will cause damage to the cable sheath and shorten the life of the core, resulting in a decrease in the service life. At present, i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/22

CPCG01N3/22G01N2203/0003G01N2203/0021G01N2203/0033G01N2203/0282

Inventor 崔学林涂怀俊杨鑫崔洋

Owner SHANGHAI NANYANG FUJIKURA CABLE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com