Power head convenient for robot to automatically exchange eccentric main shaft unit

A power head and robot technology, which is applied in the field of power heads, can solve the problems of heavy weight of the power head, hindering the popularization and application of robot helical milling holes, and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

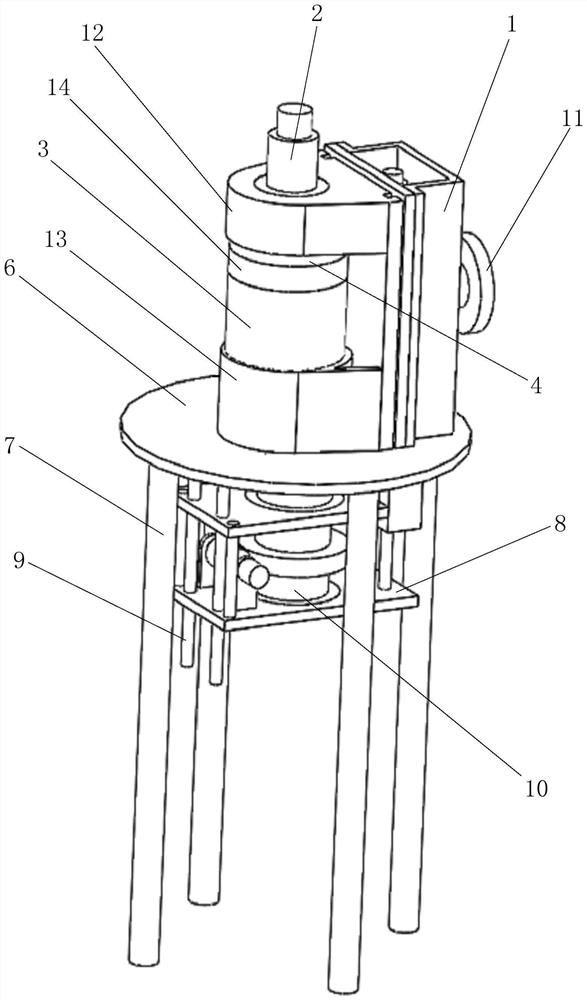

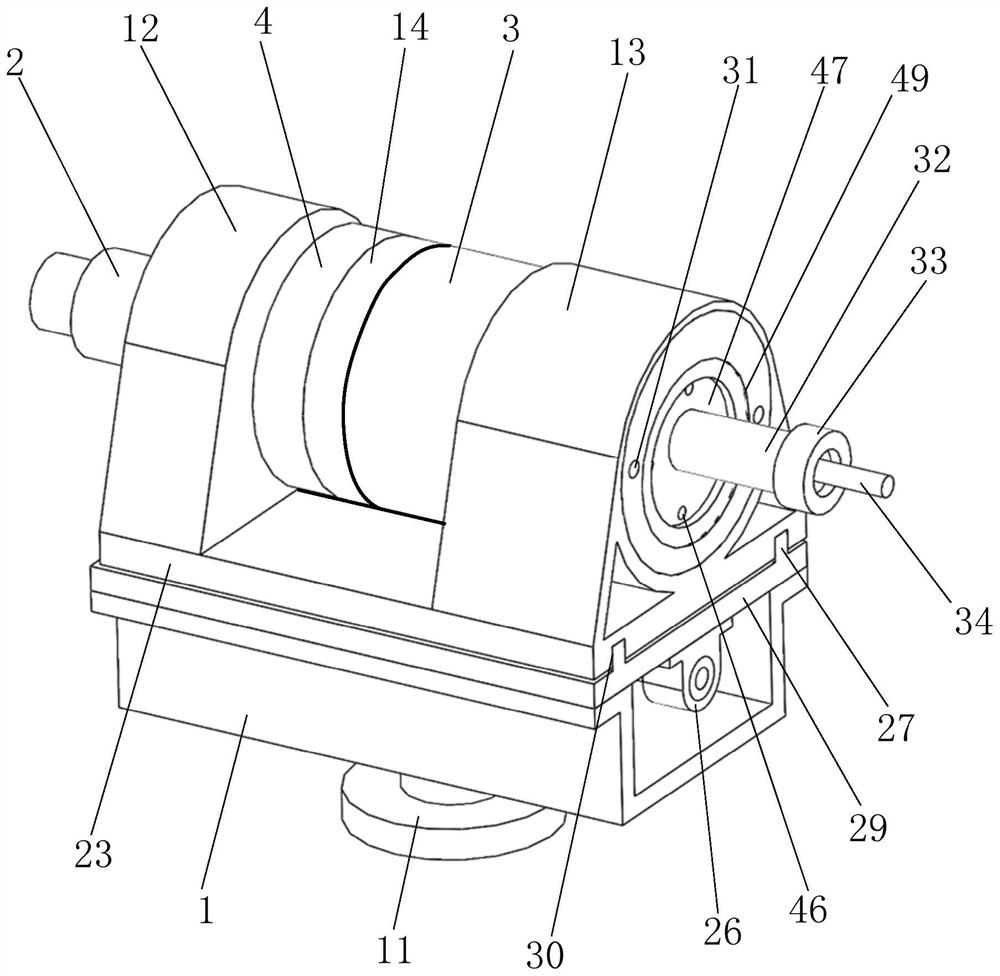

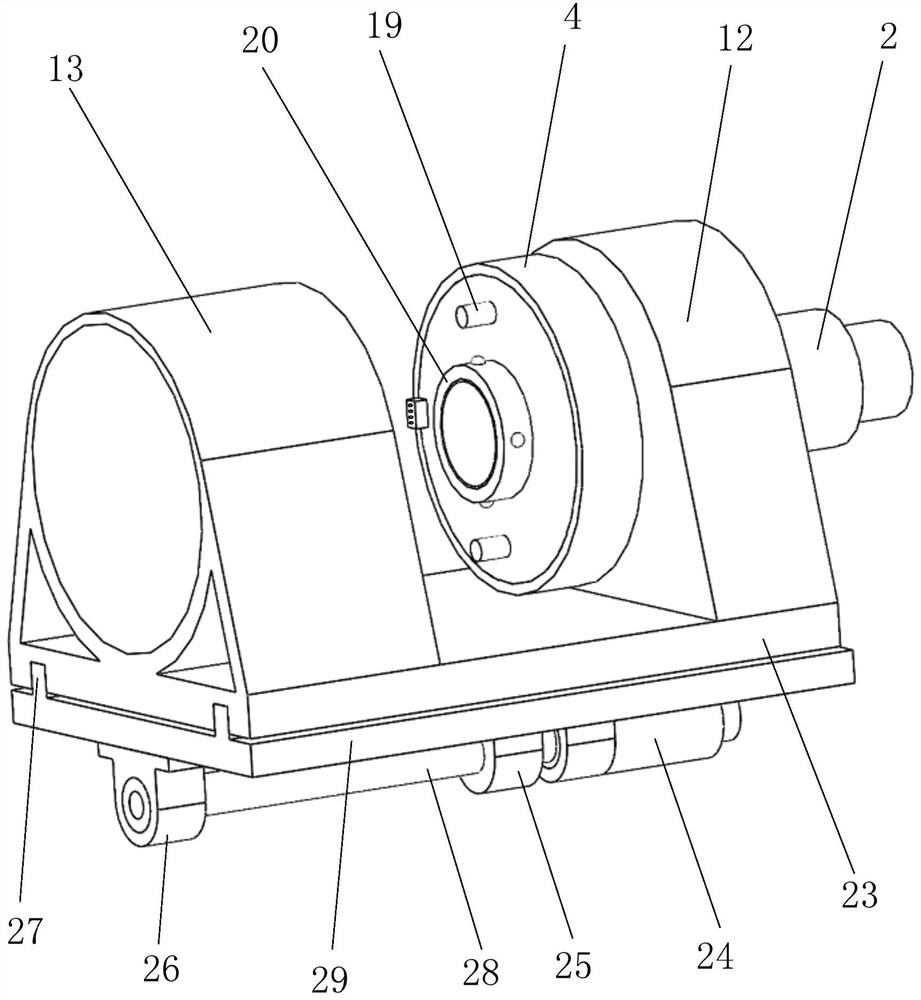

[0029] Such as Figure 1-8 As shown, the power head of the present invention that facilitates the automatic replacement of the eccentric spindle unit by the robot includes: the power head support, the feed mechanism, the revolution drive mechanism, the eccentric spindle unit, the quick docking module, the hole making tool mechanism and the tool setting table; the eccentric The spindle unit includes a revolution adjustment mechanism and an autorotation adjustment mechanism;

[0030] The feed mechanism is installed on the power head bracket, and the power head bracket is used to install the feed mechanism on the robot; the autorotation adjustment mechanism is eccentrically rotated and installed on the revolution adjustment mechanism; the revolution drive mechanism and the revolution adjustment mechanism are both rotatably installed on the feeder. On the feed mechanism, and the revolution drive mechanism is detachably docked with the revolution adjustment mechanism through the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com