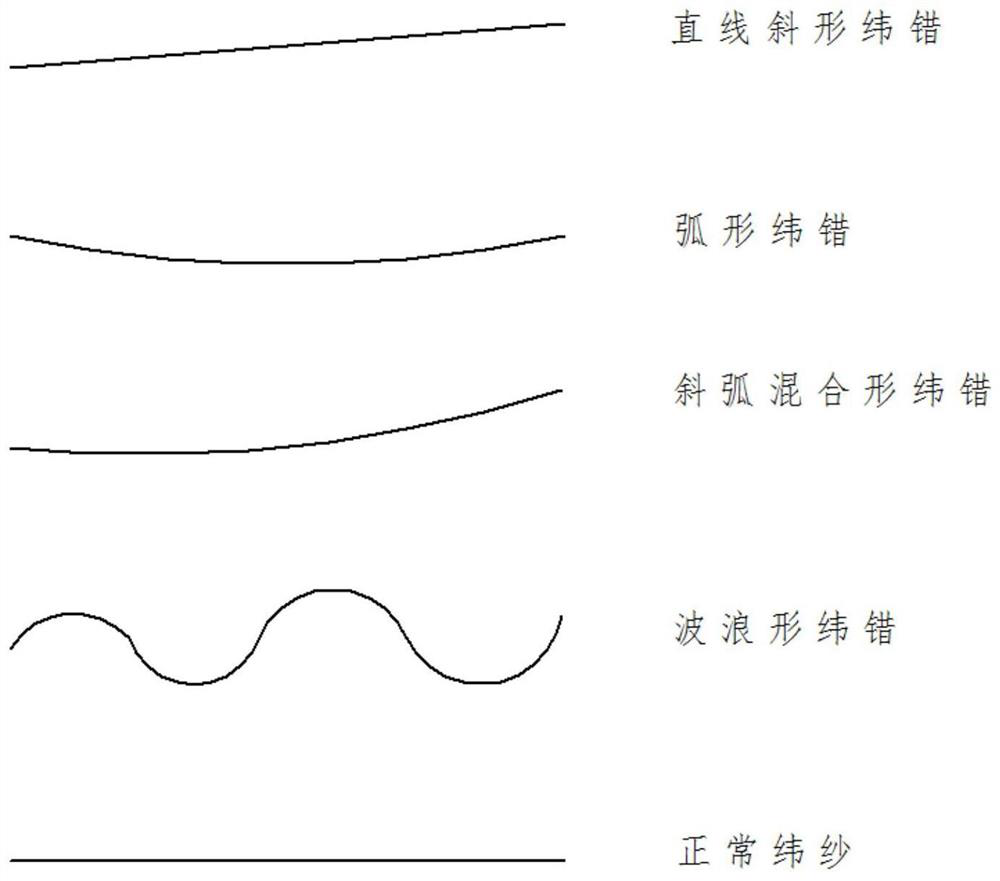

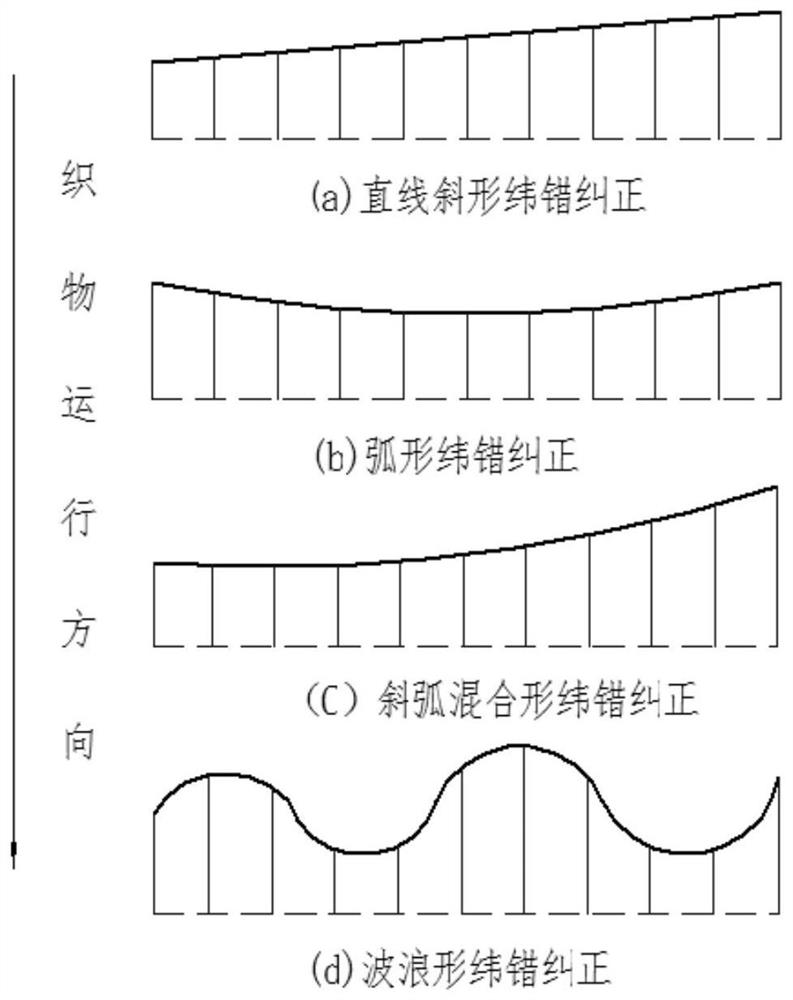

A weft adjustment method, a weft adjustment mechanism and a device for solving the wavy bending of fabric weft yarns

A wavy and fabric technology, which is applied to the field of fabric weft adjustment method and weft adjustment mechanism, can solve the problems of complicated structure design and complicated weft adjustment control, etc., and achieves great economic and practical value, good weft adjustment effect and simple structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

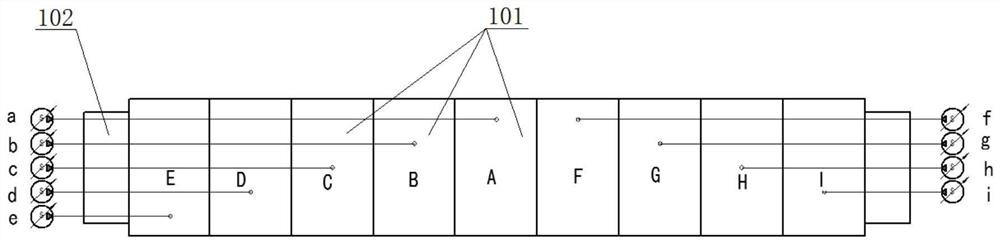

[0061] Figure 5 to Figure 13 It is a structural schematic diagram of a weft alignment mechanism for solving the wavy bend of the fabric weft yarn in this embodiment. A weft alignment mechanism for solving the wavy bending of fabric weft yarns in this embodiment includes installation shaft rollers 102 and several groups of driving rollers 101 with the same diameter, the installation shaft rollers 102 are arranged along the weft direction of the fabric, and each group of driving rollers 101 rotates axially Each set of driving rollers 101 is connected with a group of driving mechanisms for driving the driving rollers 101 to rotate and controlling the rotation speed, forming multiple transmission rollers 100 with the same diameter. Specific as Figure 5 As shown, the multi-stage transmission roller 100 with the same diameter includes an inner cylinder 2 and several groups of outer casing rollers 1 with the same diameter. The inner casing 2 is installed as the shaft roller 102, t...

Embodiment 2

[0067] Figure 14 to Figure 16 It is a structural schematic diagram of a weft alignment mechanism for solving the wavy bend of the fabric weft yarn in this embodiment. A kind of weft adjusting mechanism of this embodiment that solves the wavy bending of fabric weft yarns, its basic structure and weft adjusting principle are the same as in Embodiment 1, the difference is that in this embodiment, the driving mechanism that controls the rotation of each group of drive rollers 101 Compared with Embodiment 1, the installation space is more compact by adopting the structure form of the sleeve-rotating motor. Specifically, such as Figure 14 to Figure 16 As shown, the multi-section transmission roller 100 with the same diameter includes an installation shaft 2' and several sets of sleeve motors 1' with the same diameter, the installation shaft 2' is used as the installation shaft roller 102, the sleeve motor 1' is used as the transmission roller 101, and each group of sleeves The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com