Embroidery machine power-off protection method and system

A power-off protection, embroidery machine technology, applied in the direction of embroidery machine, embroidery machine mechanism, textile and papermaking, etc., can solve the problems of increasing the workload of operators, machine damage, damage to the machine, etc., to achieve low implementation cost, avoid mistakes Operation, high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

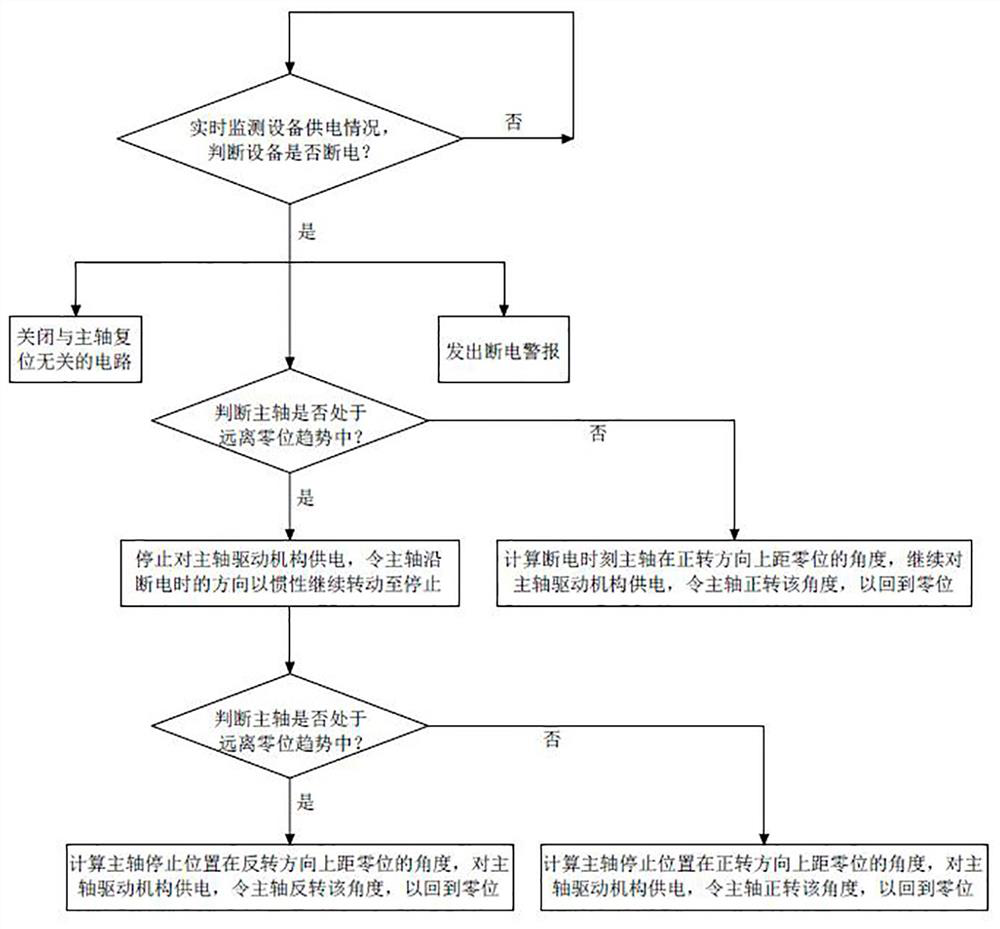

[0039] Such as figure 1 As shown, an embroidery machine power-off protection method includes the following steps:

[0040] Step 1, monitor the power supply of the equipment in real time, and judge whether the equipment is powered off. If so, proceed to steps 2, 3 and 4 at the same time; if not, continue to monitor the power supply of the equipment;

[0041] Step 2, turn off the circuits that are not related to the spindle reset, and store energy for the capacitor in the spindle drive circuit, that is, only open the monitoring circuit of the relevant spindle status or position, so as to avoid the waste of residual electric energy in the circuit and capacitor, so as to ensure that the spindle is reset. required electrical energy;

[0042] Step 3, issue a power failure alarm to notify the staff in time to ensure the timeliness of follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com