A plug-in machine for motor rotor terminals

A technology for connecting terminals and motor rotors, which is used in electrical components, electric components, and manufacturing of motor generators, etc., can solve the problems of difficult to achieve continuous plug-in operation, low production and processing efficiency, and uneven quality of finished products. Improve production and processing efficiency, improve production and processing efficiency, and stabilize the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

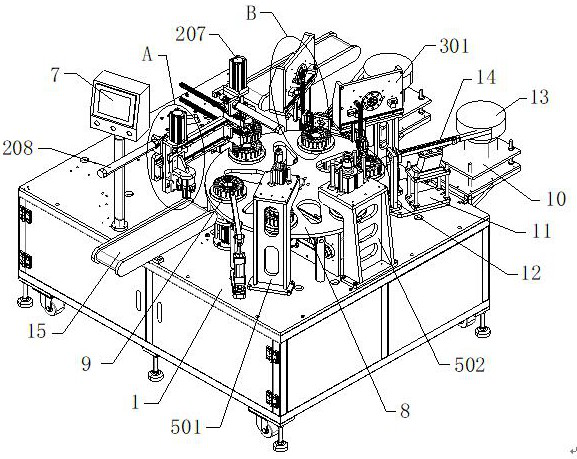

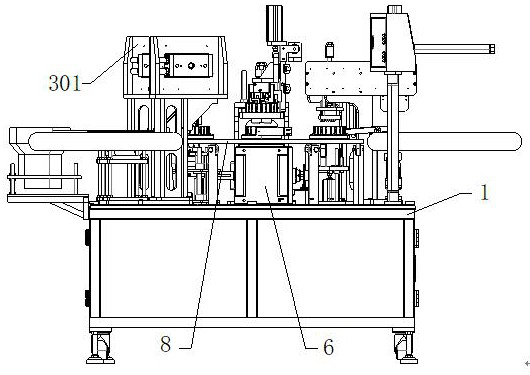

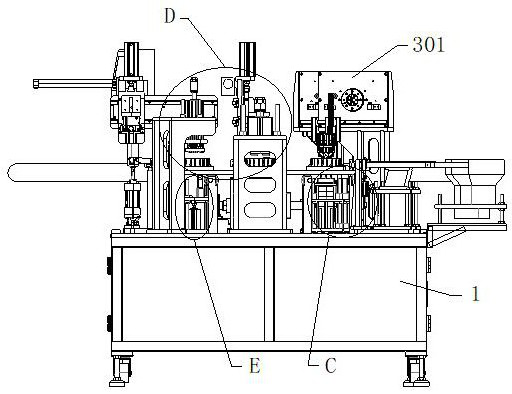

[0028] see Figure 1-10 , the present invention provides a technical solution: a plug-in machine for motor rotor terminals, including a frame 1, which is provided with a feeding and discharging mechanism 2, a plug-in mechanism 3, a top mold rotating mechanism 4 and a pressing mechanism 5. The servo motor 6 and the main control panel 7 are fixedly installed on the top of the frame 1, and the output shaft of the servo motor 6 is fixedly installed with a turntable 8 through a coupling. The top of the turntable 8 is provided with six sets of installation holes distributed in a circular array , the rotor tray 9 is installed in the installation hole, the rear side of the frame 1 is fixedly installed with two sets of mounting platforms 10, the top of the frame 1 is fixedly installed with two sets of support frames 11, and the tops of the mounting platforms 10 and support frames 11 are respectively A feeding vibrating plate 13 and a baffle plate 12 are fixedly installed, and a feeding...

Embodiment 2

[0032] see Figure 1-10 , on the basis of Embodiment 1, the feeding and discharging mechanism 2 includes a mounting plate 201, a first guide rail 202, a first sliding seat 203, a mounting seat 204, a support 205, a first clamping cylinder 206, a first cylinder 207, a hydraulic pressure Rod 208 and connecting block 209, two sets of mounting plates 201 are erected above the frame 1 and are vertically distributed above the two sets of conveyor belts 15, and two sets of first guide rails 202 are fixedly installed on the outer wall of one side of the mounting plate 201, One side of the mounting plate 201 is provided with a mounting seat 204, and two groups of first sliding seats 203 are fixedly installed on one side of the mounting seat 204. The first sliding seats 203 are slidably installed on the first guide rail 202. The seat 204 is slidingly installed, and a guide rail is fixedly installed on the outer wall of the other side of the mounting seat 204. A support 205 is slidably i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com