Variable-operating-area lifting platform

A technology of operating area and lifting platform, applied in the direction of lifting device, lifting equipment safety device, etc., can solve the problems of difficult expansion, fixed operation area, affecting the work efficiency of workers on the lifting platform, etc., to increase the scope of application, increase Great construction efficiency and the effect of increasing the horizontal span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

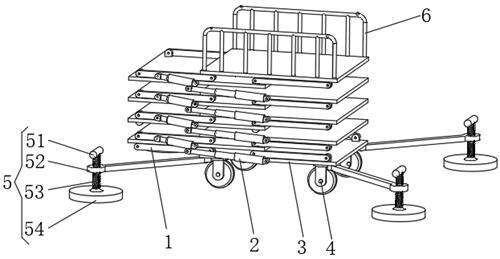

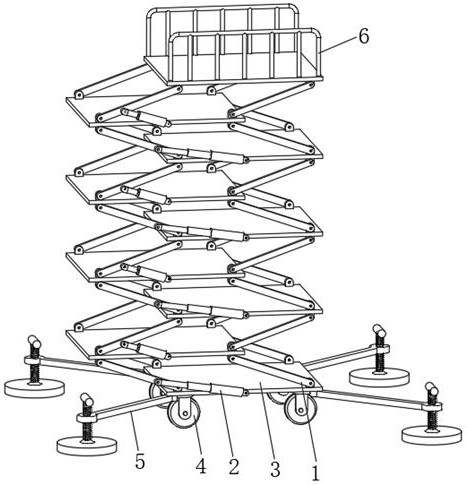

[0032] Example 1: See figure 1 , figure 2 with image 3 This example discloses a lifting platform that can be variable, including a plurality of plates 3 disposed in the vertical direction, and a flat plate 3 is provided, and a highly adjusted member is mounted between the two flat plates 3.

[0033] The height adjustment member includes a drive member 2 and a connecting rod 1 of no less than two parallel settings, and both ends of the connecting rod 1 are rotated on the surface of the adjacent two flat plates 3, and the driver 2 drives one of the connecting rods 1. Turn, the connecting rod 1 between the two flat plates 3 and the two flat plates 3 makes the two flat plates 3 constitute a class parallelogram structure, and the two flat plates 3 can be missed in parallel in the longitudinal direction, and two flat plates 3 The distance between the vertical direction varies with the rotation of the connecting rod 1.

[0034] The driver 2 of each height conditioner 2 drives the connect...

Embodiment 2

[0051] Example 2: Figure 4 with Figure 5 As shown, the present embodiment discloses a lifting platform having a variable operation area, which is substantially the same as the structure of the embodiment, and the present embodiment is, in addition to the upper plate 3, adjacent several The flat plate 3 is offset from the same side; Figure 4 As shown, the flat panel 3 offset from the same side makes a newly added working station, and the newly added working station increases the construction efficiency when it is necessary to work in different high construction work in the same location.

[0052] Further, also including the guard lever 7, both ends of the outer peripheral side of the guard lever 7 fixed a finite block 71, and the upper and lower plates 3 above the same side shift plate 3 are opened, and the guard lever 7 is up and down. The ends are connected to the two card connectors, and the guard lever 7 provides support for the two flat plates 3 above the newly added working s...

Embodiment 3

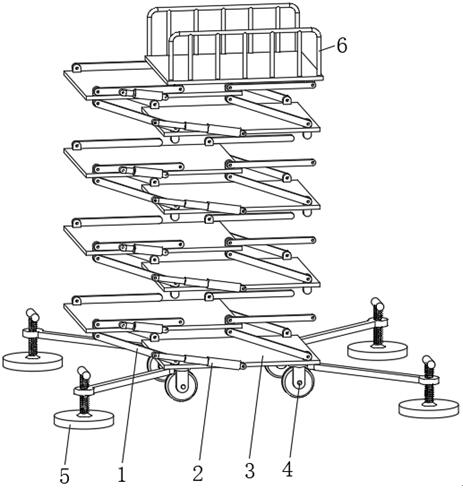

[0055] Example 3: Figure 6 , Figure 7 with Figure 8 As shown, the present embodiment discloses a lifting platform having a variable operation area, on the basis of the first embodiment or the second embodiment, each of which is offset to one end of the length direction thereof; tablet 3 Composition of the ladder, the upper plate 3 is in place, on or fixed on the high object, or placed on the bottom plate 3, or the bottom plate 3 is fixed or welded to the outer place plane on.

[0056] This lifting platform in the state of the ladder is convenient for people's up and down, and the people under fire, rescue, etc. are rapidly evacuated; or facilitate operation of the heights with debris below.

[0057] Such as Figure 7 As shown, a number of adjacent flat plates 3 is inclined together, increasing the lateral span of this lifting platform, increasing the application range of this lifting platform.

[0058] Further, the mounting holes are opened on the plate 3, and the two ends of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com